Shank adhesion confirmation realizes ultra-precise machining

Machine tool industry

A machine tool manufacturer that produces machining centers.

A designer of ATC consulted us on "Adhesion confirmation" of the shank.

Table of Contents

Client’s Issues

The client had a trouble with the small chips put between the "tool holder" and "shank" during the tool change on CNC vertical machining center.

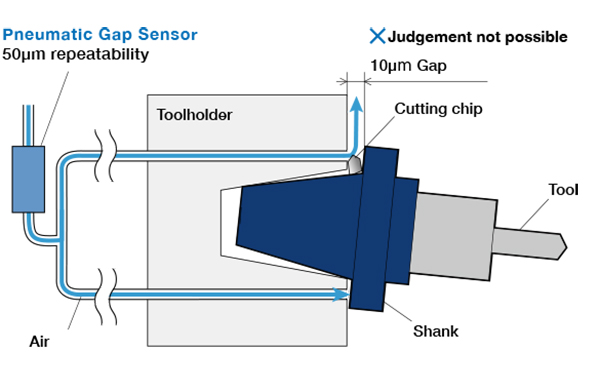

The "Air sensor " has beenused to confirm the adhesion of the shank through the air holes on the tool holder, however, because of the low detection accuracy 50μm, the uplifts by 10 μm cutting chips cannot be detected.

Even a slight uplift of the shank results in processing defects.

He needed a high-precision air sensor and got to know Metrol by the visit of our booth at JIMTOF.

The main focus of the issues

A 10µm slight uplift caused by cutting chips should be detected.

Poor adhesion of the shank produces defective products.

Metrol’s suggestions

Conventional pneumatic "gap sensors" are intended for "existence detection" of workpieces and not suited for precise "confirmation of adhesion".

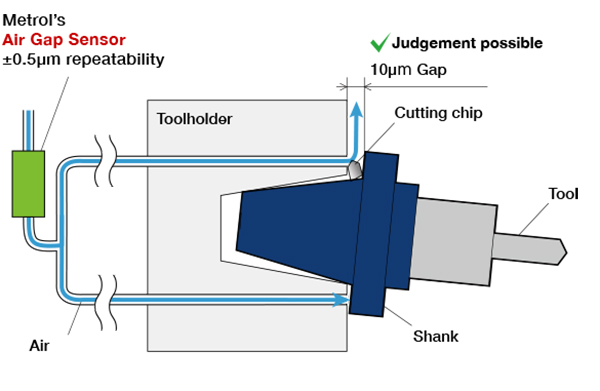

Metrol's "Air Gap Sensor [Short range detection type]" is capable of ±0.5μm repeat accuracy and can consistently detect gaps of 1μm.

Installing in the tool changer of a CNC machining center allowed the detection of a 10μm gap in which cuttings became stuck between the shank and tool holder.

Prevents machining errors due to tool floating, achieving ultra-high precision machining with machine tools.

In addition, use in pre-existing air piping is possible, eliminating the need for bothersome air pipework design and making installation easy.

Improvements

A 10µm slight uplift caused by cutting chips can be detected reliably.

Adhesion confirmation of the shank realizes precision machining.

Comment from Metrol representative

Not only machine tool manufacturers but also many machine users have troubles with processing defects caused by cutting chips put between the taper shank and tool holder.

If you are looking for high-precision pneumatic sensors, do not hesitate to contact us!

For further information about the products used in this application

Air Gap Sensor [Short range detection type]

±0.5µm repeatability!

Capable of checking the precise seating of workpieces and jigs, making ultra-accurate machining with CNC machine tools possible.