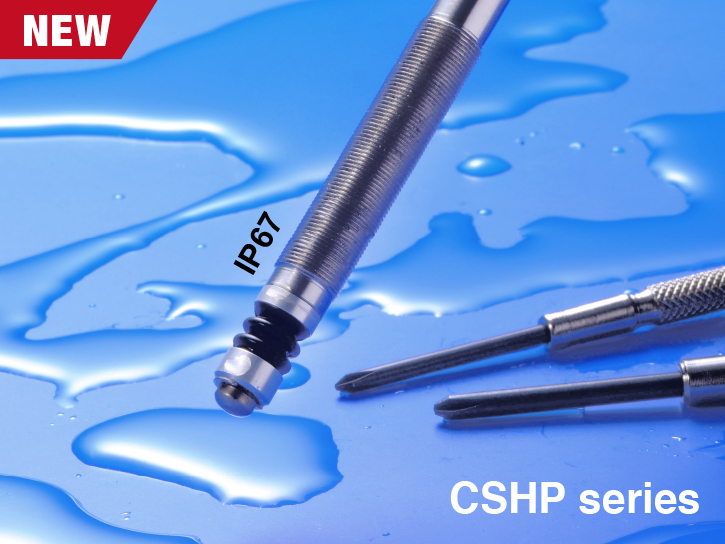

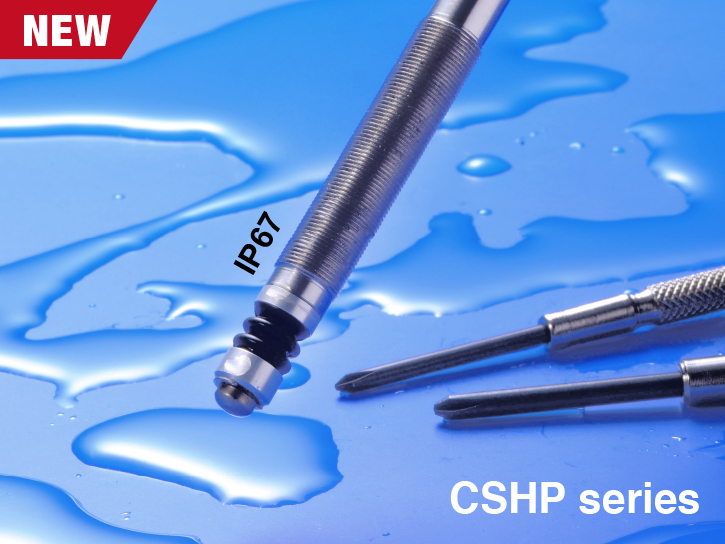

New Touch Switch, CSHP.

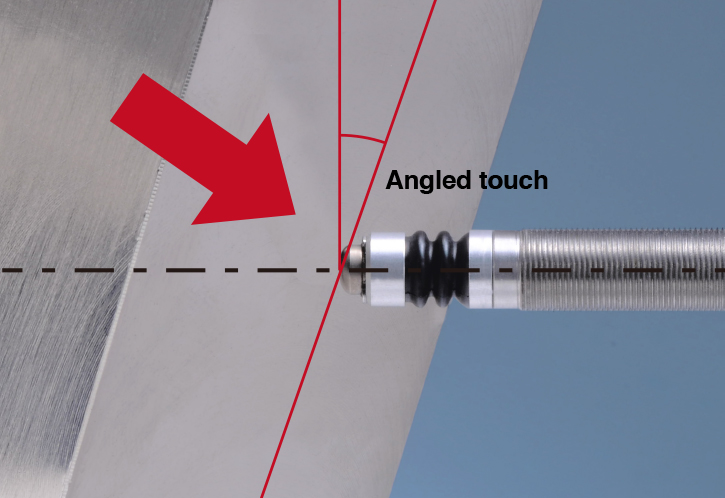

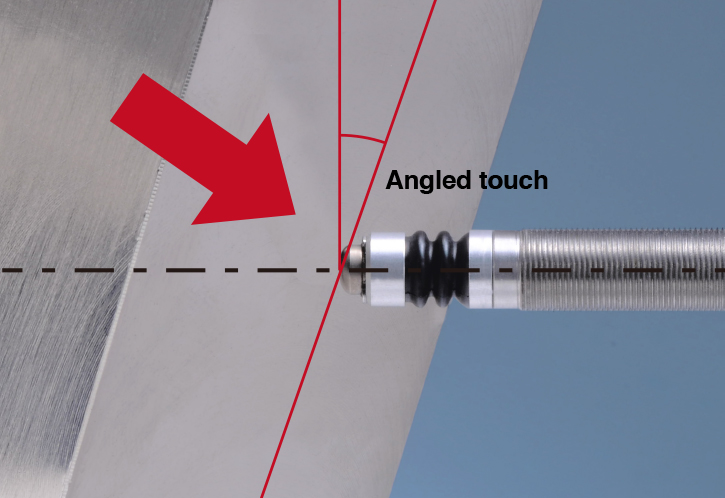

CS Touch Switch [CSH Series] makes it possible to support workpieces from all directions.

The [H] in the model name stands for Japanese word "Henkaku", which means "Angled touch".

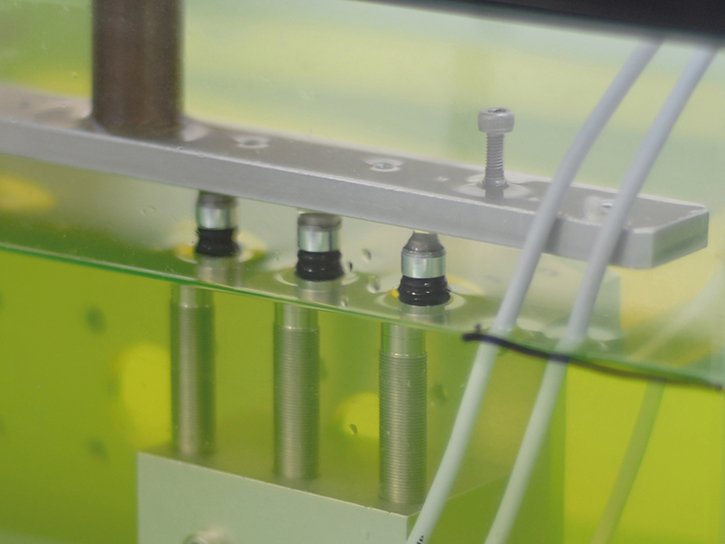

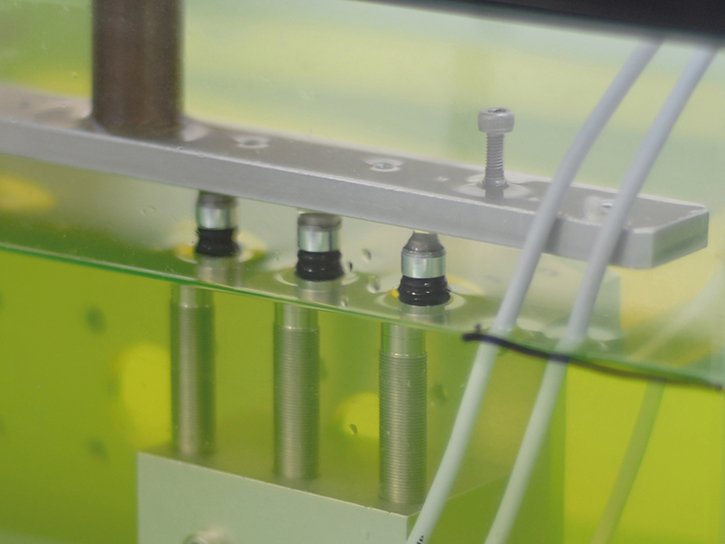

Adopts a linear bushing bearing that is strong against vibration and shocks, as a long-time selling product for Metrol.

In 2014, the newest addition to the series 〔CSHP〕 has been developed.

IP67- High waterproofing and coolant resistant properties are designated by a 〔P〕at the end.

The origin of development

As a tough "Precision Positioning Switch" which doesn't break even if it hits the workpiece declination,

the [CSH Series] has consistently expanded in sales since its release as it garners more and more customer support.

However, the existing product has IP65 protection so was not completely waterproof and was slightly thick with an M12 outer diameter.

"Cannot be used in places where cutting oil may splatter."

"Not enough mounting space for an M12 sized unit."

Despite the need for positioning switches supporting declination angles, they cannot always stand up to the needs of the customer...

That irritation was the origin of [CSHP].

Foreseeing the birth of a long-seller

(1) Resistant to harsh environments, (2) Robust enough to withstand workpiece detection from all directions, (3) High accuracy, (4) Compact.

No positioning switch could satisfy all of the criteria, even from the group of Metrol sensor products spanning 700 types.

A switch that is both waterproof and robust would be unrivalled.

Product development of [CSHP] was launched, with Engineer S in the lead.

Drowning prototype...?

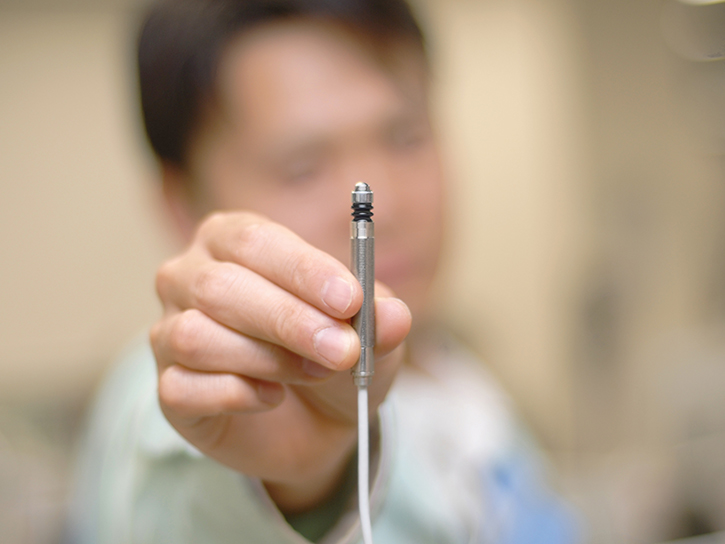

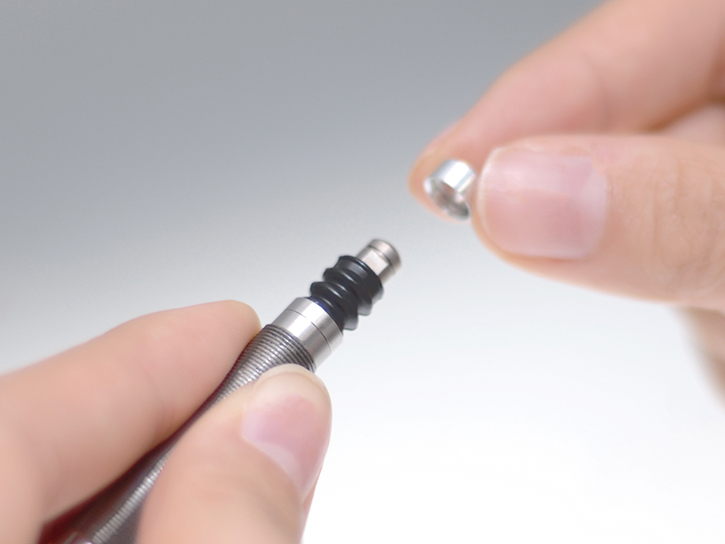

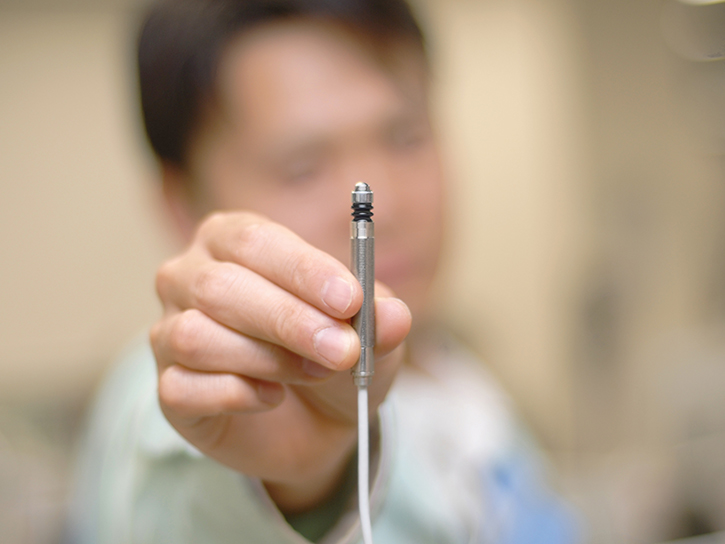

A new prototype model was soon completed that slimmed the previous model down from an M12 diameter to M8.

Its characteristic linear bushing bearing had both improved robustness and a slim body.

The seemingly simple development had one major problem in its path -- waterproofing.

IP67 waterproofing tests require air pressure to be applied to the switch interior as it is submerged in water.

All the completed prototypes had air leakage from somewhere, causing bubbles to escape.

This means that waterproof protection could not be guaranteed.

An IP67 switch ought to be sealed...

So where is the leakage coming from...?!

Waterproof and the rubber boot

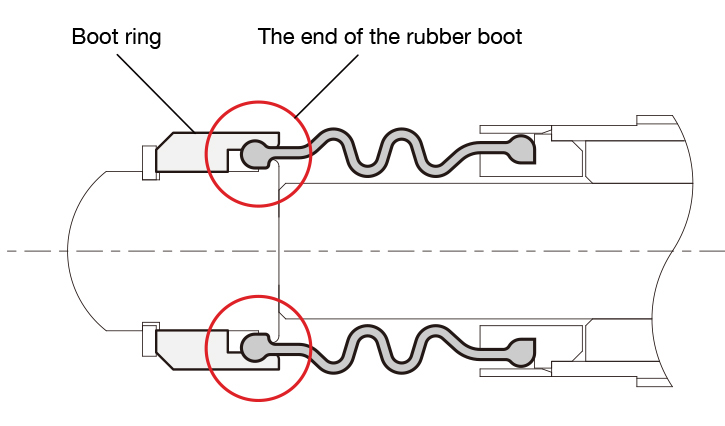

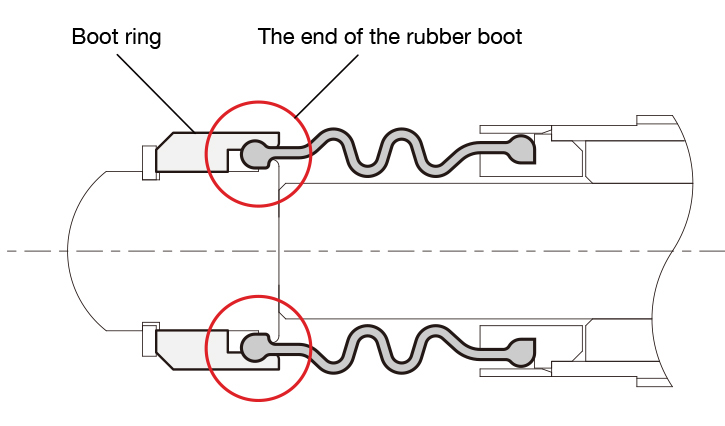

The air escape path was in the rubber boot.

Metrol's rubber boots are specially created products packed with our waterproofing know-how.

The raw ingredients consist of a special mixture that gives them not only great waterproof qualities but also coolant resistance.

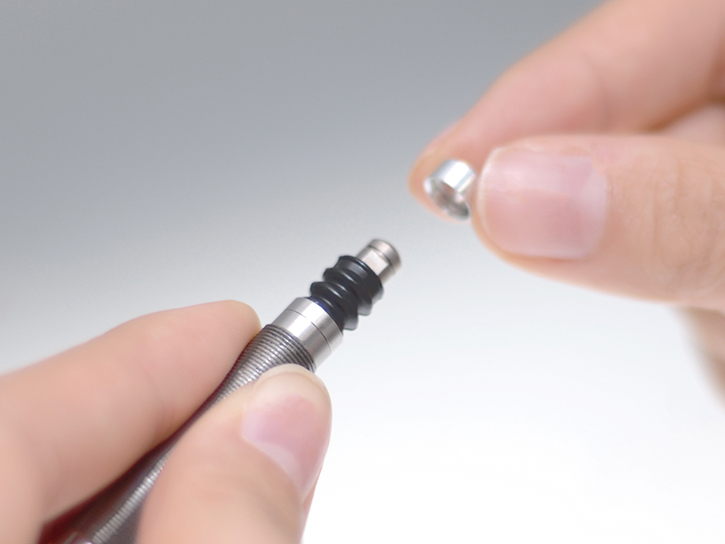

The cause was found to be the "crushed state" of the rubber boot.

Each end of the rubber boot pushes on a boot ring in a design that increases the sealing performance of the switch.

However, the crushed state of the boot was insufficient, forming a minute gap which allowed water to penetrate.

However, if the boot is crushed too much then assembly issues would result.

The rubber boots become hard, making them difficult to insert and leading to rubber damage.

The best “crushed state” of the rubber boot

Not too loose, not too hard.

In order to achieve such an ideal rubber boot, we re-designed the boot ring shape through repeated delicate compromises.

The slim M8 outer diameter made those tactics even more stringent.

Build and submerge, build and submerge...

Limited by the ease of assembly without damaging the rubber boot and the constraint of leaving no gaps large enough for water to penetrate.

After pursuing the borders of the two constraints we finally stumbled upon the answer.

We then conducted cutting oil resistance tests by submerging in a tank filled with coolant.

The rubber boot successfully prevented oil from penetrating, guaranteeing IP67 protection even with cutting oil.

Through trial and error

We added the [P] mark that indicates IP67 waterproofing, and [CSHP] was born.

Even in poor environments in direct contact with water and coolant,

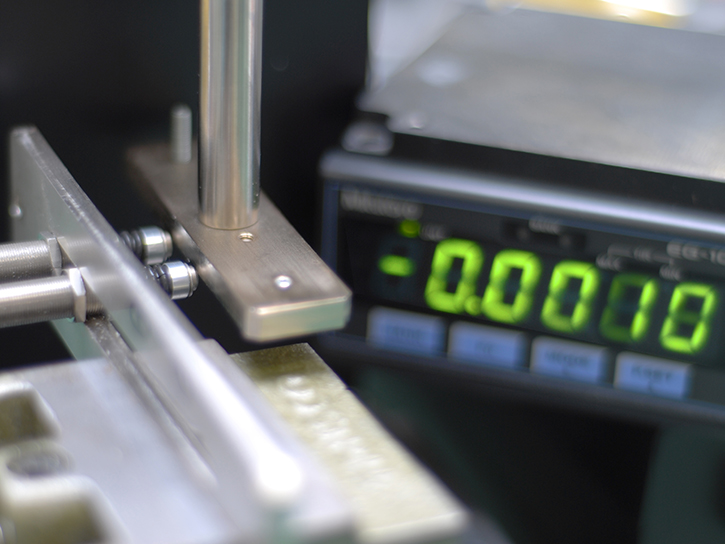

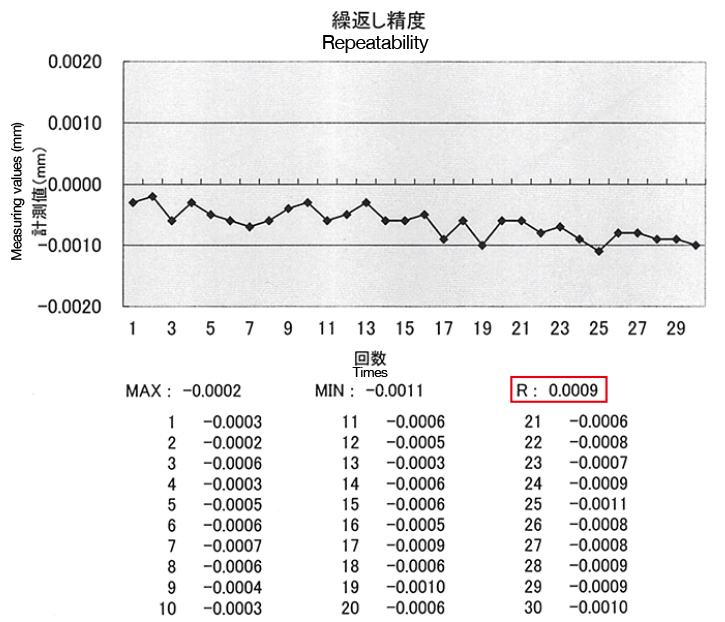

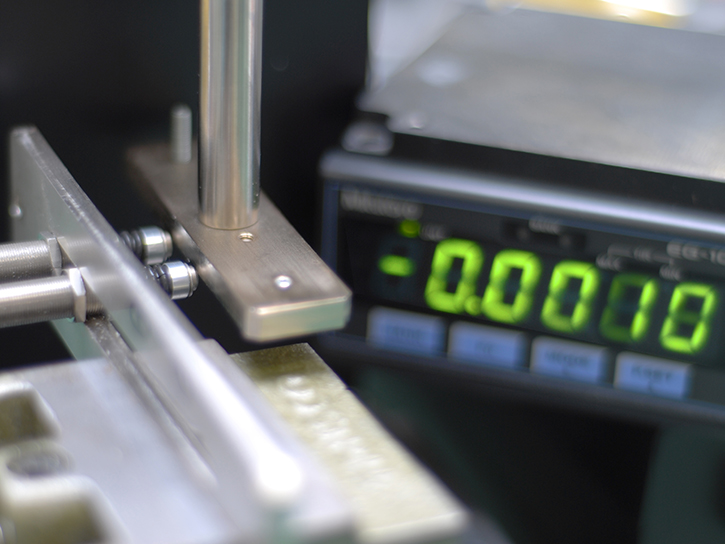

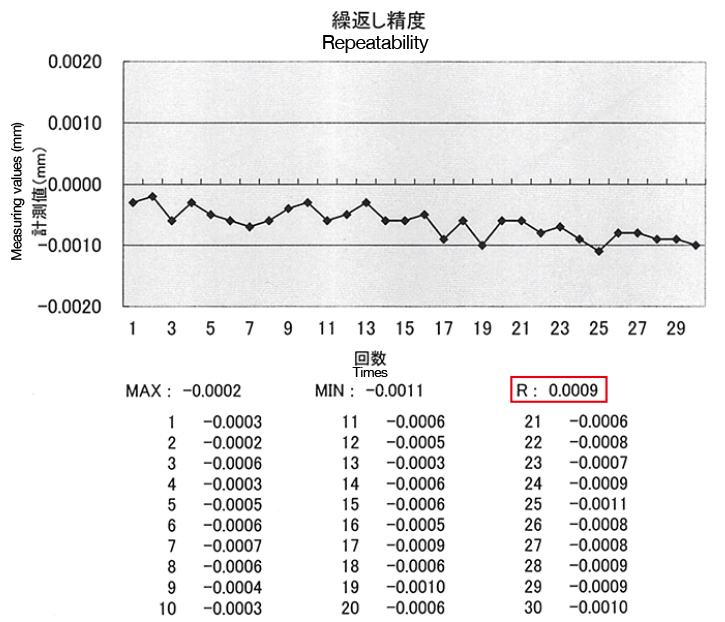

even striking the workpiece from the side, the repeatability is 5μm.

Durability tests conducted over 2 months showed an accurate lifetime guaranteed for more than 10 million operations.

High precision and Long life.

The greatness of the [CSH Series] still continues to this day.

No matter where it is・・・

Slimmed down from an M12 size to M8 while both waterproof and robust.

This was the debut of the new [CSHP] products with a shape changed beyond recognition from conventional products.

Slim, strong against harsh environments and capable of striking the workpiece from all directions.

If in doubt, get this!

The ease of use that [CSHP] boasts really comes down to its true toughness.

"No environment in which it cannot be used"

Performance affirmed by the development engineers themselves.

[CSHP] has no weak spots.