MISSION

As a true professional in sensor development,

METROL responds to your needs with sensors designed exclusively for you.

Since our founding in 1976, METROL has supported the improvement of productivity and reduction of defects in machine tools, robots, and medical equipment, to name a few, and we are professionals in the field of "precision positioning sensors".

Even if you require a solution that has never been applied in the past, we will plan and design a custom-made product designed exclusively for you from ground up. This capability is backed by our unique design and development team, which has provided custom-designed sensors to more than 200 equipment builders worldwide.

Many of the customers we consult with have various restrictions and requirements regarding the environment in which the controls, tools, and sensors are used, as well as the mounting space and operating speed of the equipment. We propose the best sensors for your challenges based on careful hearings, a deep understanding of what you want to achieve, and our extensive experience and proven track record.

We not only propose sensors, but also applications that add value to your equipment.

METROL is ready to support you in strengthening your competitiveness and shortening your development timeframe. Please inquire us regarding your current challenges at your convenience.

MACHINE BUILDER

Equipment Manufacturers

We Have Collaborated In The Past

※一部抜粋

REASON

How METROL Wins Customers

REASON 01

Impactful Development Team with high expertise in sensors, positioning and machine tools

REASON 02

Project management skills to work closely with the client's development team

REASON 03

Quick prototyping with our own equipment

REASON 04

Strong production capacity to produce customized products

REASON 05

99.7% or more parts are procured in Japan and Made-in-JAPAN for accelerated production.

PRODUCTS

Main Products Available for Customized Orders

NEEDS

Most Popular Custom-order Needs To Date

Material Specification / Modifications

・Need to be designed with non-outgassing materials for vacuum environment application

・Please quartz the contact probe to prevent damaging the workpiece.

・I am a user of particular machine, and the casing and boot covers corrode, so I want different material.

Size Specifications

・Need a switch that fits in a space of mm.

・I want the fitting dimensions changed to match the drawings.

・I need the distance between the contact surface to the mounting surface less than mm.

・Please build it with a tool length of 20φ.

Motion Specification

・I would like to keep the contact force below ___N because the detected object is easily damaged.

・Having Pre-travel (PT) would be appreciated.

Shape Modifications

・Please modify contact probe / surface shape to match the workpiece material

・I want the stylus to be made to the desired dimensions.

Improving Maintenance

・We want to make it easy maintenance by attaching connectors.

・I want the sensor contact / probe / surface to be removable.

Other Inquiries

・Please remove the interface.

・Need it designed to 200°C heat resistance specifications.

・I need to increase coolant resistance.

・Please make it wireless specs.

・I need a 2 point setting, both with NC output.

・We want to change the LED display color.

・I want it customized to I/O-Link specifications.

CUSTOM-MADE

Past Customization Projects

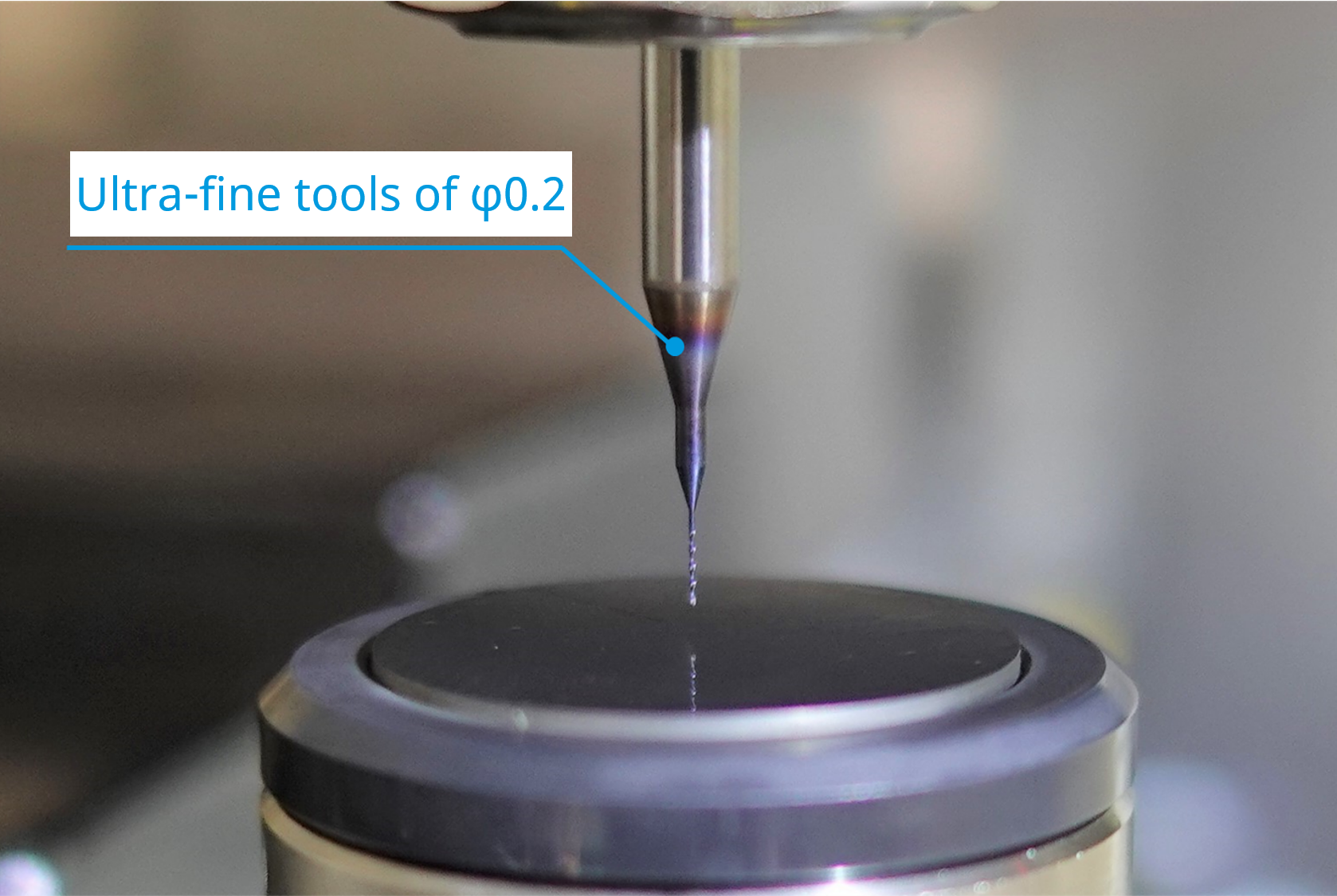

Case 1:

Customization request order from machine tool manufacturer

Development of a tool setter perfectly compatible with our machining centers

Exclusively designed tool setter

Details of Customization Request

・Want two signals, a deceleration signal and a tool length measurement signal, and be compatible with equipment control.

・Smooth sliding of bearings to comply with small-diameter tools.

・Need to make contacts detachable.

・Want to attach a quick one-touch detachable base.

Standard tool setter

(prior to customization)

One-touch detachment for space saving when not in use

Replacing only contact probe / surface enabled and low cost

Capable of measuring ultra-fine tools of φ0.2 without damage

Mirror finish prevents snagging and small-diameter tools from breaking

Case 2:

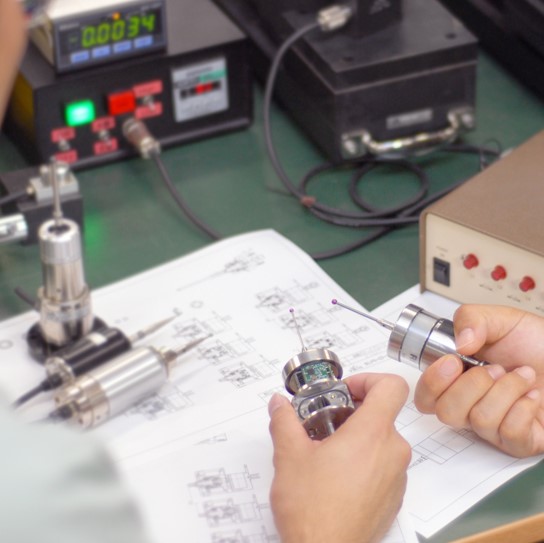

Customization request order from touch-probe user

A variety of customization of micro touch probes

Exclusively designed touch probe

Details of Customization Request

・Narrowing of the diameter to fit the equipment.

・Make it SUS based (modification of material).

・Attaching connectors directly to the sensor for better maintenance.

・Adding a flange for mounting on equipment.

・Make it wireless due to wiring difficulties.

Standard model

(prior to customization)

Material modified model

(Top: SUS / Bottom: Aluminum)

Model with connectors directly attached

Model with a flange for mounting

Wireless model (probe + transmitter)

*Receiver included separately

Model with Screw M16 x 1 for mounting

FLOW

Flow of Customization and Special Orders

Please be reminded that this is a standard case.

The actual process and timeframe will vary depending on the specifications and agreements upon discussion.

STEP 01

Inquiry by contacting us

STEP 02

Discussion on specifications

(visits or online)

STEP 03

Specification agreement

STEP 04

Drafting

(1-2 weeks)

STEP 05

Exchange of drawings

STEP 06

Quotation

STEP 07

Purchase Order

FORM