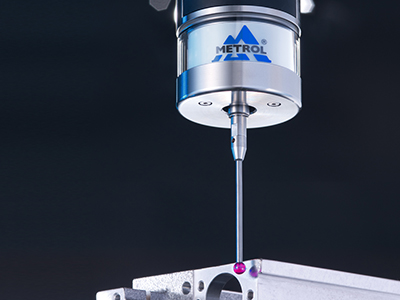

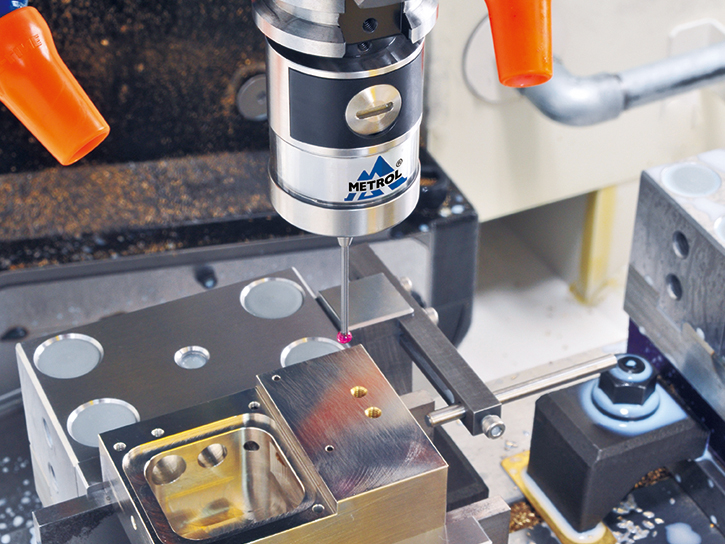

What is “3D Touch Probe”?

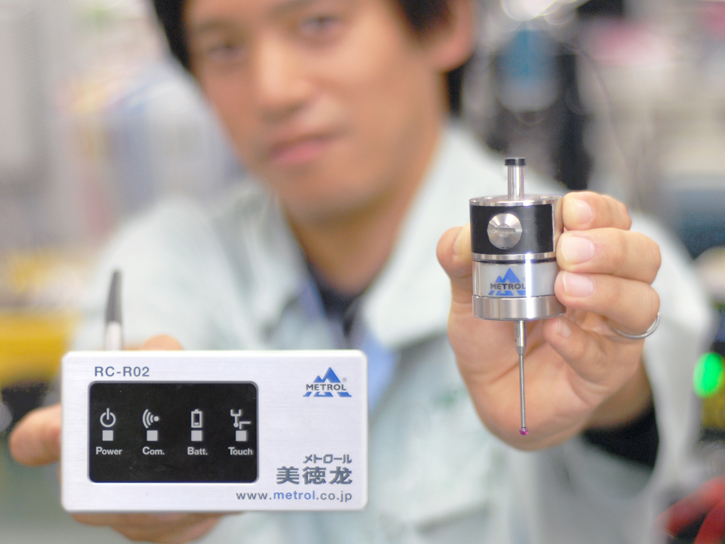

3D touch probes are measurement devices mounted inside industrial CNC machines

for measuring the length, width and height of workpieces in 3 dimensions

in order to improve the machining accuracy of machine tools.

Most of these are expensive products imported from overseas.

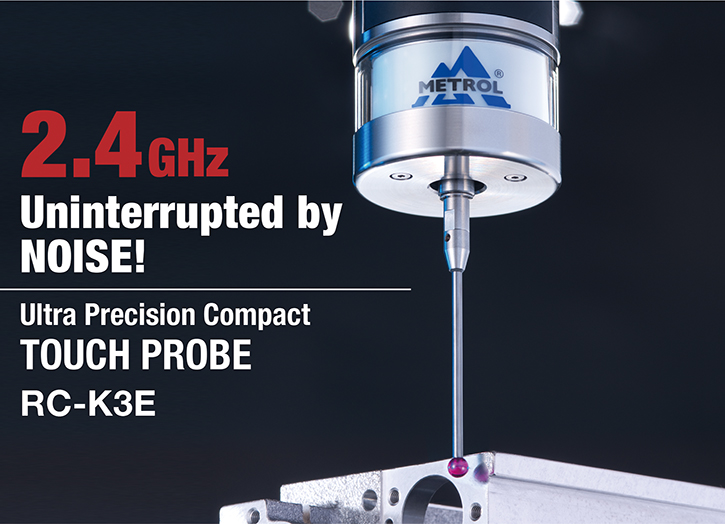

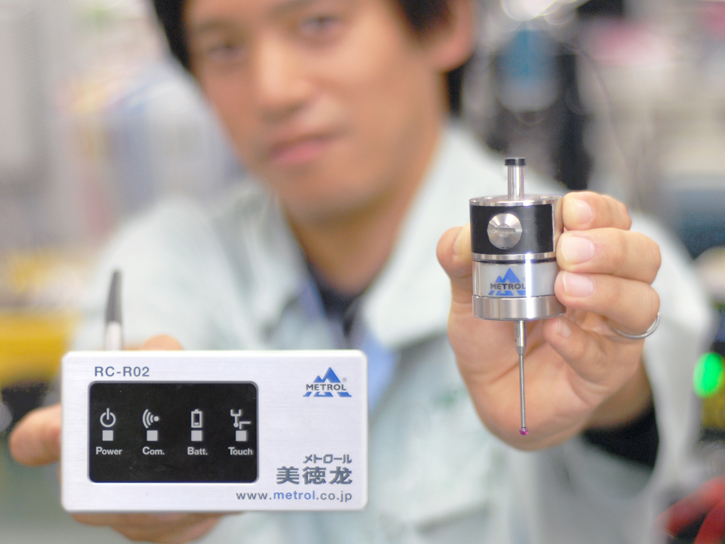

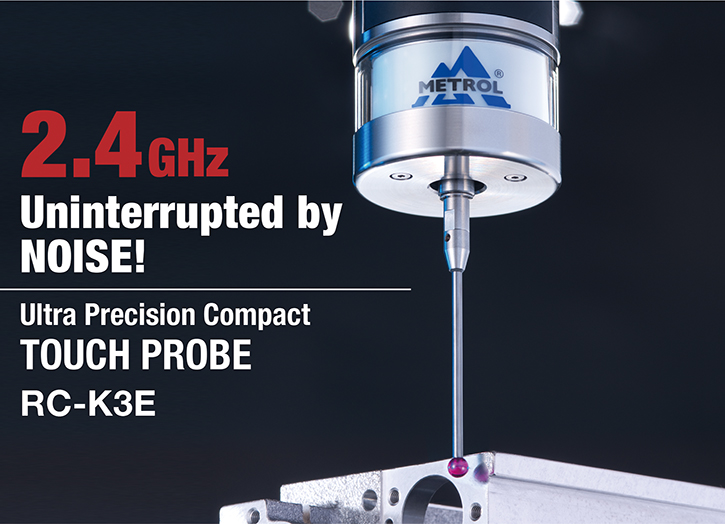

Metrol's Wireless 3D Touch Probe [RC-K3E] achieves 1μm repeatability not possible with conventional infrared 3D touch probes and can send and receive signals from multiple directions.

The weaknesses of wireless communication, such as noise or electrical interference in harsh environments,

have been overcome to create a 3D Touch Probe capable of consistent communication from multiple directions.

For stable and reliable communication

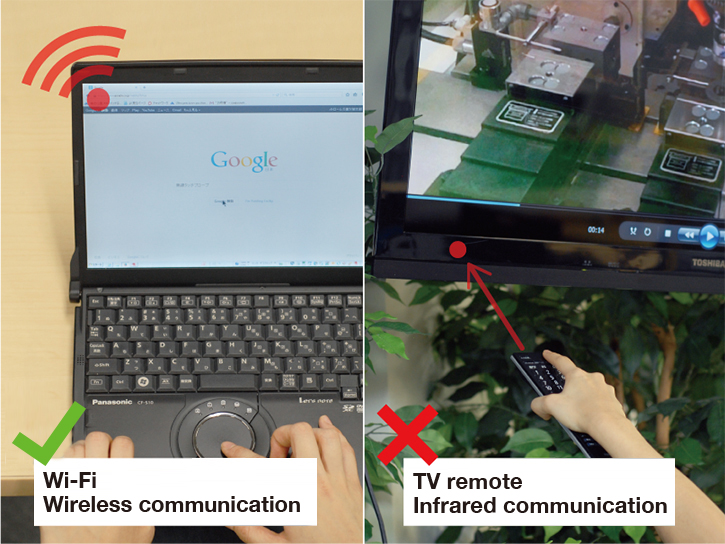

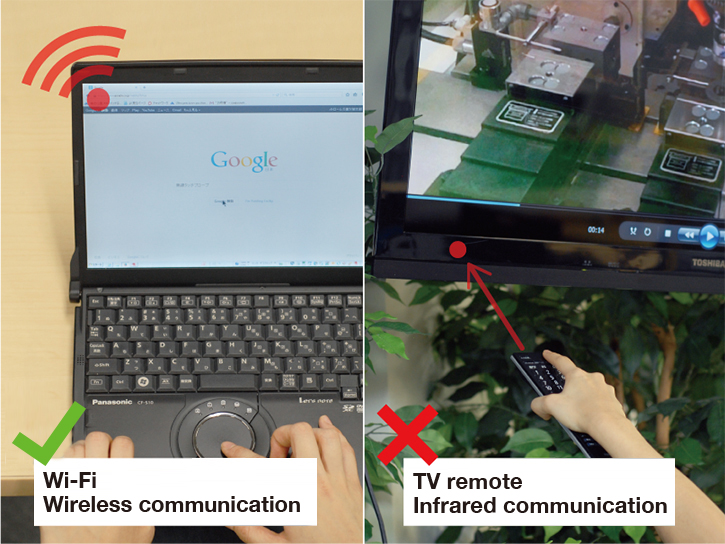

The common method of wireless communication for 3D touch probes is infra-red optical communication.

It is used when you change channels on TV.

Infrared communication works well in linear directions, but becomes blocked if objects are in the way and cannot be used for long distance communication.

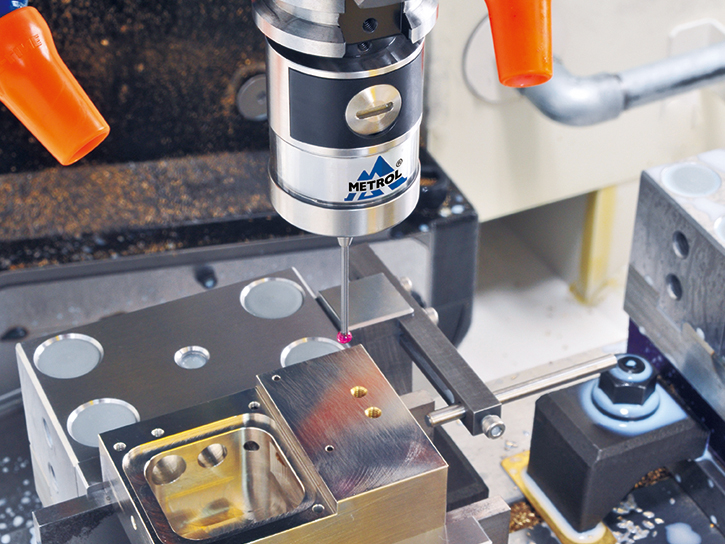

In recent years the shapes of workpieces have grown more complex and machining technology has grown more diverse,

increasing implementation of 5-axis machinery or robots, and in turn leading to increased demand for wireless communication devices that work from multiple directions.

Remote controls don't work unless they are directly pointed at the receiver.

Everybody uses Wi-Fi because it is less stressful and more useful.

However, unlike in office or household environments, the motors and other machinery in factories cause electromagnetic interference, making high reliability wireless communication impossible.

Metrol engineers have always challenged themselves in developing products resistant to harsh environment.

The next challenge should be developing reliable wireless communication which is able to work under harsh environment without being interrupted by noise.

Fusion of application and new technologies

Communication in the 2.4GHz ISM band has great versatility and can be shared with multiple wireless systems, but has insufficient reliability for industrial applications.

It is important to develop a wireless communications system that can withstand noisy factory environments in order to increase communication reliability.

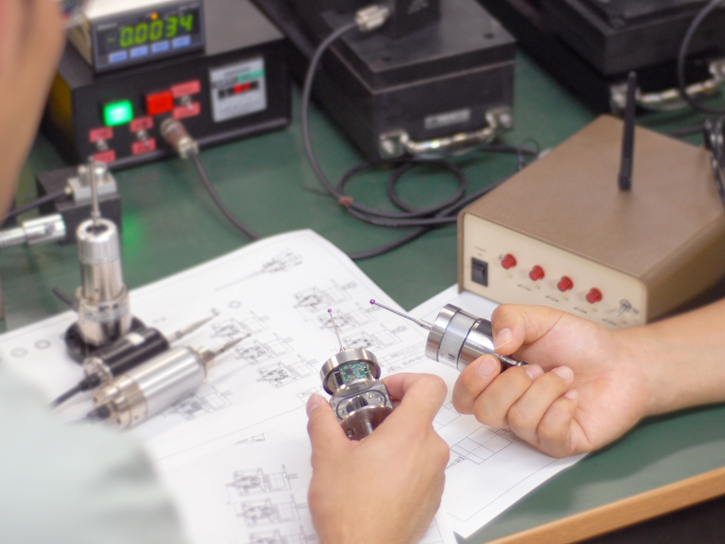

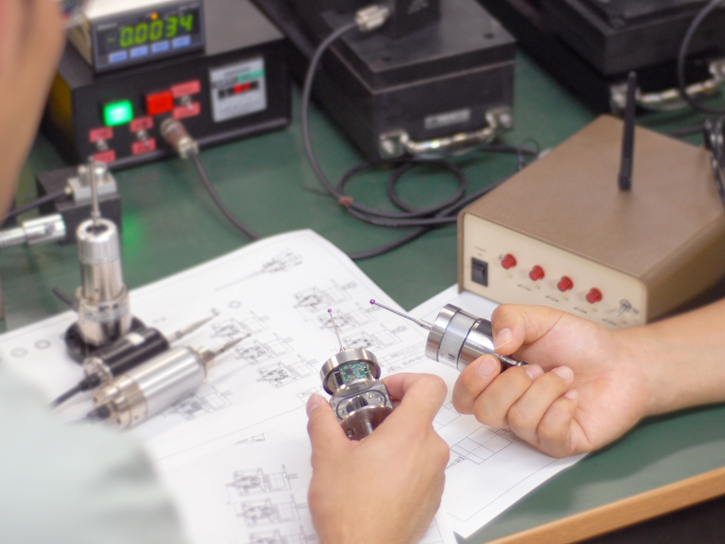

Mechanical and communications engineers hence teamed up to develop a wireless communication method that works uninterrupted.

A prototype was created that uses the accurate mechanical technology of conventional wired touch probes equipped with a wireless system structure perfected through simulations.

Finally, precise communications evaluation tests began.

Invisible obstacles...?

Few days past after starting evaluation test.

Errors, however, would frequently occur around noon on weekdays and in the evenings of specific days of the week.

Are there any system or mechanical problems?

It was disturbing that they always occurred with similar timing.

When we looked for the cause, both the system and mechanical sides were problem-free, so it was determined that external noise must be having an effect.

However, what could be causing such noise during lunch break?

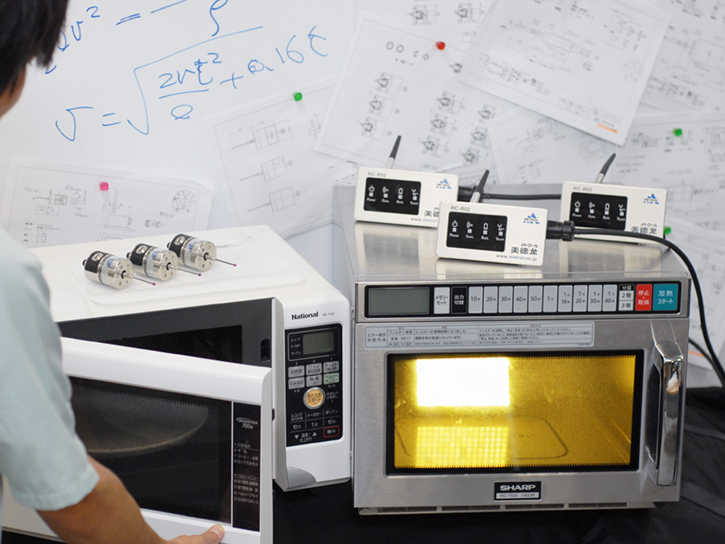

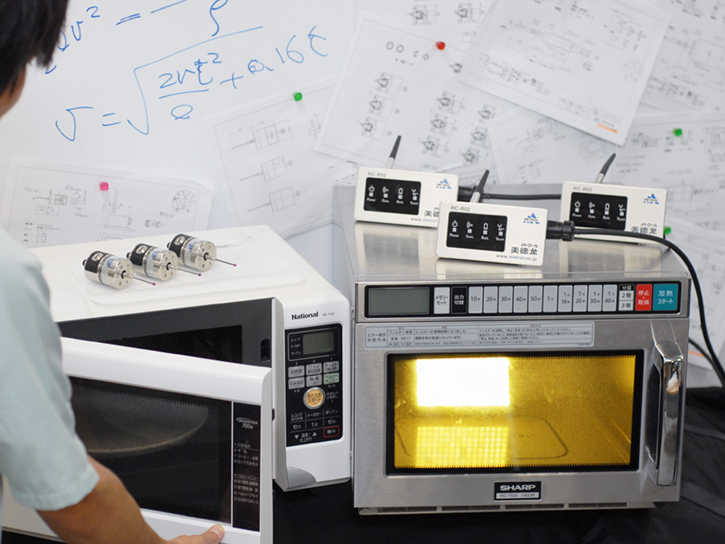

Several microwave units are used at once during lunch in order to heat up food.

To test if this was the culprit, the microwave units were turned on at a shifted time period...

As anticipated, communication errors occurred.

Noises from the microwaves caused the communication errors.

The root cause of the frequent errors in the evening was also thought to be related to planes flying over the airspace above the factory.

There are a big air base around Metrol, and airplanes and helicopters fly above the factory.

Best environment for evaluation tests

The development environment for the new product had to make the best of the fact that it happens to be in a noise-prone environment, and evaluation tests were conducted in an even harsher noise environment.

A microwave unit was placed next to the product and the signal stability of the transmitter evaluated.

When an error display was generated, we analyzed the data and reconfigured the system.

Accidentally conducting tests in a particularly noisy environment rather than that of a regular factoryhelped to perfect a wireless communications system with high reliability.

Strength in unique technology

The completed wireless communications system incorporates international standards and proprietary state-of-the-art technology.

As the wireless communications band is shared, external signals intertwine making communication unstable.

Our unique searching technology that switches the frequency used makes it possible to achieve stable communication by instantly catching mixed information.

Furthermore, in addition to improving the signal stability of the system structure, International Standard ISA100 has been adopted to give security to the transmitted information while reducing communication errors to approximately 1/6 as many as conventionally occur.

Ending is beginning.

A highly reliable wireless communications system capable of transmitting signals from multiple directions,

something that is very difficult using infrared signaling without influence from objects in the way, has been achieved and is actively used for 5-axis processing equipment, robots and large CNC machinery both domestically and internationally.

By creating a wireless communications system with high reliability in factory environments,

not only a 3D Touch Probe but several new products including Air Gap Sensors have been developed and release for sale!