One of the features of Metrol's "Precision Pisitioning Switches" is high water-proofness.

Metrol has been pursuing "water-proof sturucture" so that the switches can work in high accuracy without being damaged or affected by harsh environments where coolant and cutting chips exist.

The water-proof type "Precision Positioning Switches" that was co-invented with TOYOTA in 1977 have IP67 protective structure, making it possible to be used even in automobile manufacturing lines.

In order to prevent coolant as well as water from penetrating, the IP67 switches are completely sealed.

Full inspection to guarantee water-proofness

After assembled, all IP67 "Precision Positioning Switches" are inspected one by one to check water-proof structure.

Apply air pressure to the switch interior and inspect it for air leakage by using an internal pressure meter.

In case the value is abnormal, submerge the switch in water so as to find out where the air leakage comes from.

In this way, we can examine the part which is not completely sealed and think of the ways to make better products next time.

The secret of water-proof structure

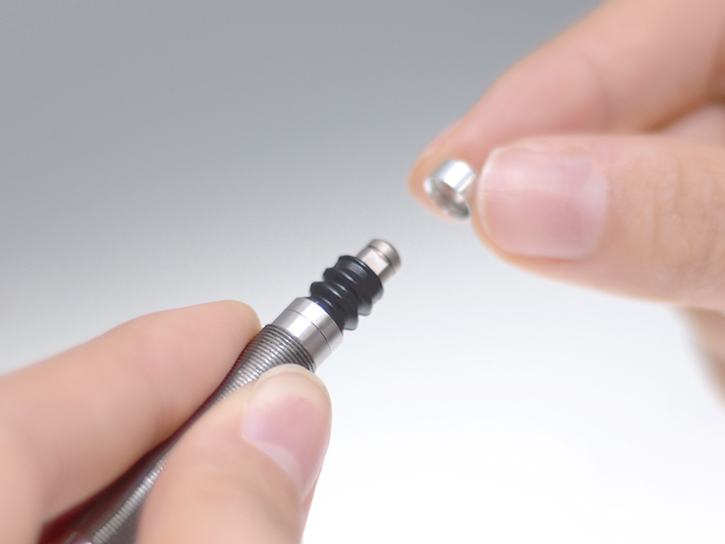

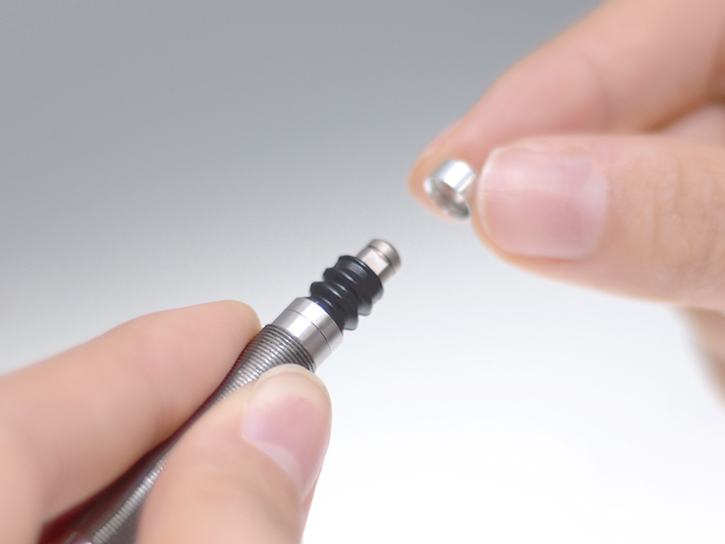

What is essential for sealing structure of the switch is the black rubber bellows boot.

Metrol's rubber boots are made from the raw ingredients consist of a special mixture that gives them not only great waterproof qualities but also coolant resistance (mainly for alkaline coolant).

This unique and special rubber boots realize water-proof structure that has high durability against harsh environments where coolant and cutting chips splutter.

Packed with Metrol's waterproofing know-how, IP67 type "Precision Positioning Switches" have been continuously adopted to various manufacturing sites and used for precision positioning under harsh working conditions including automobile production lines and CNC machine tools.