The precision switch included in a ball plunger miniaturizes the equipment

Industrial equipment industry

The client is a manufacturer of assembling equipments for automobiles.

A representative of the design department inquired us about "indexing " using a ball plunger.

Table of Contents

Client’s Issues

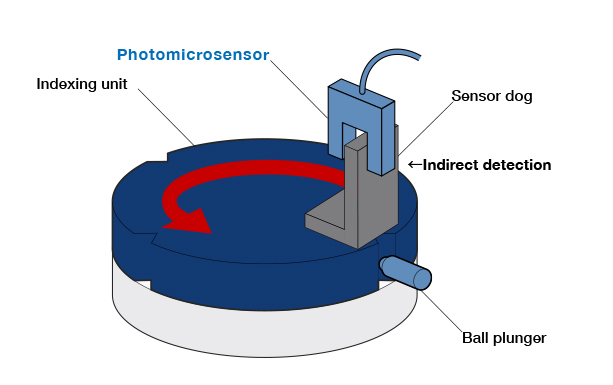

The photomicrosensor and ball plunger have been used for confirming the position of the indexing unit, however, the sensor dog is needed, which requires a lot of installation space.

Reducing the size of the equipments was an urgent task because the client had many indexing units to be installed.

He contacted Metrol through the website, looking for the way to downsize the equipments.

The main focus of the issues

The sensor dog for photomicrosensor requires a large installation space.

Metrol’s suggestions

The sensor dog must be provided when using the "photomicrosensor" which is not suitable for directly detecting the object.

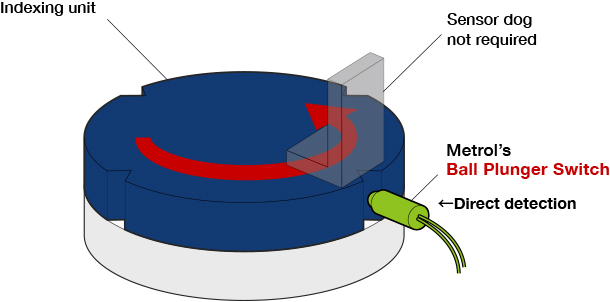

Houing a precision switch in a ball plunger, Metrol's "Ball Plunger Switch" can play two roles in one device and provide identifying and positioning functions as well as output a confirmation signal.

The indexing unit can be miniaturized dramatically by reducing the numbers of components.

Improvements

The indexing unit can be miniaturized by using the ball plunger which has a built-in precision switch.

Comment from Metrol representative

Like this case, many manufacturers have succeded in machine miniaturizing by using our "Ball Plunger Switch" in applications such as "positioning" of the glass substrate on a conveyor and "Detecting the starting point" of the XY table.

If you are in trouble with "index positioning" of the indexing unit, please feel free to contact us.

For further information about the products used in this application

Ball Plunger Switch

The Ball Plunger with a Built-in Switch!

Able to provide identifying and positioning functions using notches on index rotating or sliding objects as well as output a confirmation signal.