Features

Non-contact detection of the machining origin of the rotary grinding wheel with ±0.5µⅿ repeatability

For super abrasive wheels such as diamond and CBN, non-contact detection with an accuracy of 1µⅿ is achieved without stopping the rotation of the grinding wheel.

Outputs 3 identification signals

The amount of air-cut is reduced by setting three thresholds:

(1) deceleration signal, (2) judgment signal, and (3) overtravel signal.

It is also possible to distinguish up to three different types of grinding wheels with as many grit sizes.

Grinding wheel diameter and thermal displacement compensation available

By detecting the grinding wheel from two directions, Z-axis and Y-axis, “grinding wheel wear” and “thermal displacement” in the machine axis direction can be detected and compensated.

Reduces machining cycle time

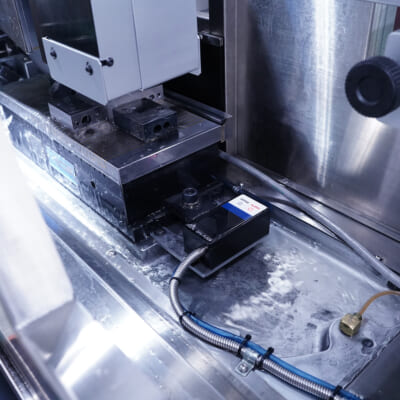

IP67 rating for protection against water, coolant, and dust, and the sensor can be installed inside the machine for shorter air piping.

Shorter pipe length improves signal response and contributes to shorter cycle time in mass production lines.

Coolant flooding tests and severe durability tests are conducted on machine tools assuming that they will be used in adverse environments.

Supply air self-diagnostic function

The self-diagnostic function outputs an alarm when an error occurs in the air supply pressure.

It notifies you of insufficient pressure, pressure fluctuation while the sensor is in use, and excessive pressure.

![Air Gap Sensor [DPA-PLR2B Series]](https://metrol-sensor.com/wp-content/uploads/2021/02/img_products_air_gap_sensor_dpa-plr2b.png)