Replacement of air micrometers drastically reduce the cost of inner diameter measurements

Automobile industry

An automotive parts manufacturer that produces handle parts for major automakers.

A representative of the machine development department consulted us on "measuring inner diameter" after the drilling process.

Table of Contents

Client’s Issues

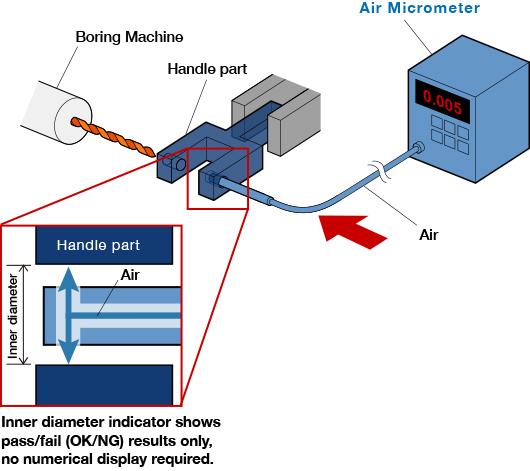

An "air micrometer" has been used for measuring inner diameter of the hole after machining, however, the device was expensive and this was a financial burden.

The client consulted major sensor manufacturers and tried a optical sensor, however, it can not measure inner diameter correctly because the hole is too small.

We received an inquiry through an internet search for an affordable sensor capable of inner diameter measurements, based on demands for cost reduction from automobile manufacturers.

The main focus of the issues

Air micrometer costs a lot.

Metrol’s suggestions

For a measurement in automated lines for detecting constant positions, the number display is often unnecessary, and "air micrometer" gives the machine overperformances for such application in many cases.

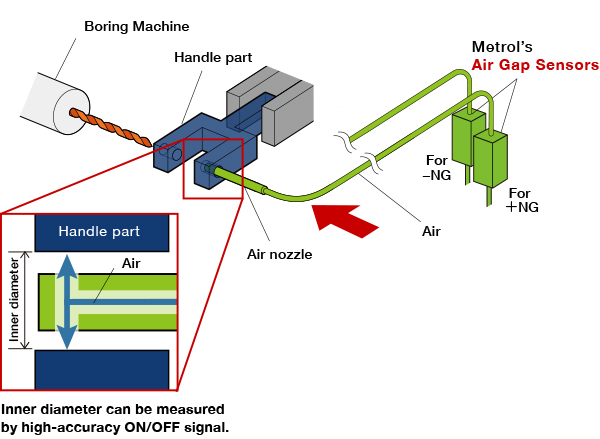

The inner diameter can be measured by high accuracy ON/OFF signals.

Though the accuracy of the switch is the same as that of air micrometer, the switch can reduce the cost to about 1/5 by eliminating the number display.

Improvements

Reduced the cost to 1/5 by eliminating the number display.

Comment from Metrol representative

"Air Gap Sensor" was featured in a famous japanese journal of manufacturing for its high accuracy and reliability.

If you are considering cost reduction by replacing an air micrometer, please feel free to contact us.

For further information about the products used in this application

Air Gap Sensor [Short range detection type]

A significant cost reduction can be realized by replacing an air micrometer with Air Gap Sensor.

Continuously adopted in the automotive industry for its high accuracy!