Detects seating of die cast components with rough surfaces with ±5μm accuracy

Automobile industry

An automotive parts manufacturer that produces die casting parts for major automakers.

A representative of the machining department consulted us on "seating confirmation" of the parts in cutting by CNC machining center.

Table of Contents

Client’s Issues

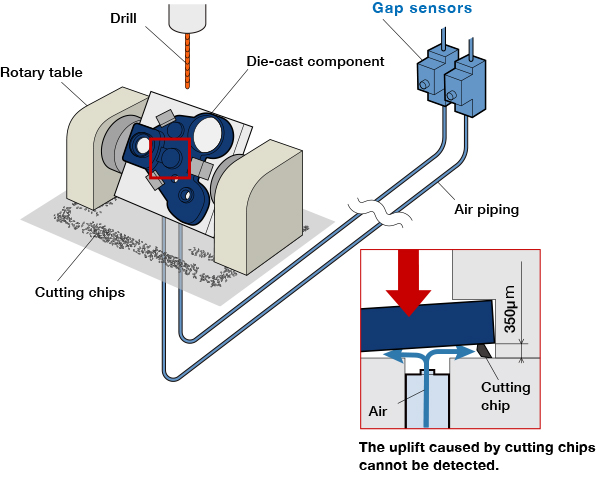

The client had a trouble with the processing defects caused by the small chips put between the "jig" and "die cast component" when chucking the component to the rotary table in cutting by CNC machining center.

A pneumatic gap sensor was used to detect the seating of die cast components;

however, the low repeat accuracy of the sensor meant that it couldn't detect accurate seating of rough die cast component, leading to accurate seating failing the tests and multiple incorrect detections.

The rough surface leaves a large gap between the jig and the workpiece, requiring a sensor that can detect the seating with good accuracy;

they found Metrol's sensor by the visit our booth in JIMTOF2014.

The main focus of the issues

Accurate seating detection is needed on rough-surfaced workpiece.

Metrol’s suggestions

Gap sensors used for "existence detection" of machining work materials have variance in the repeatability for longer detection distances, making them unsuitable for use checking the seating of large work materials or materials with rough surfaces, such as die cast components.

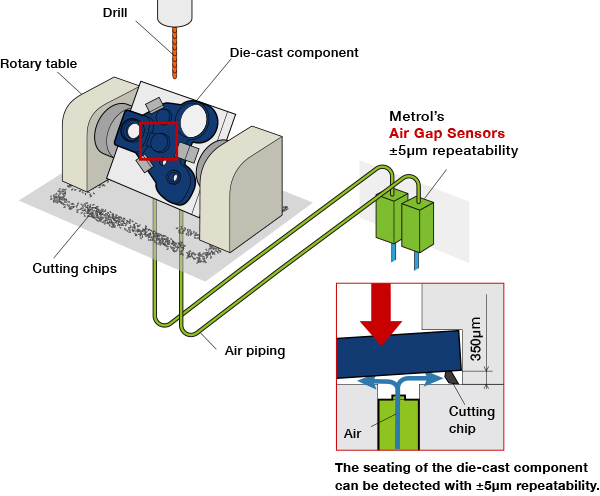

Metrol's new Air Gap Sensor supports long distance detection up to 350μm with a repeat accuracy of ±5μm.

The threshold value can also be easily set by inserting the master in the jig then pressing one button, and accurate seating verification of rough aluminum die cast components or large workpieces is made possible, achieving an ultra-accurate industrial CNC machine.

In addition, the sensor is resistant to harsh working conditions by IP67 protective structure, by installing it inside CNC machine tool where cutting chips or coolant splatter,

・Air piping: 12 → 1.5m

・Response speed: 5 → 0.8 seconds

The considerable productivity of Air Micro Switch has been realized.

Improvements

Accurate seating confirmation on rough-surfaced workpiece was realized with ±5µm repeatability.

Comment from Metrol representative

The Air Gap Sensor introduced here was developed in response to cries such as, "If only there was a gap sensor capable of detecting accurate seating for rough-surfaced aluminum die cast workpieces or large workpieces with high repeat accuracy, then we could prevent defective machining..." from the customer.

At JIMTOF(Japan International Machine Tool Fair), a lot of visitors lookd excited to see its high functionality and high precision.

If you have any troubles with the gap sensor for its low repeatability, please do not hesitate to contact us.

For further information about the products used in this application

Air Gap Sensor [Long range detection type]

350μm long detection distance.

Achieves 5μm repeatability for accurate verification of jig and workpiece seating!