Consistent detection of 10μm gaps between tire mold and jig

Mold industry

The client is a mold manufacturer who produces tire mold for major automakers.

Production technology managers consulted us on adhesion verification of jigs and molds when performing milling work.

Table of Contents

Client’s Issues

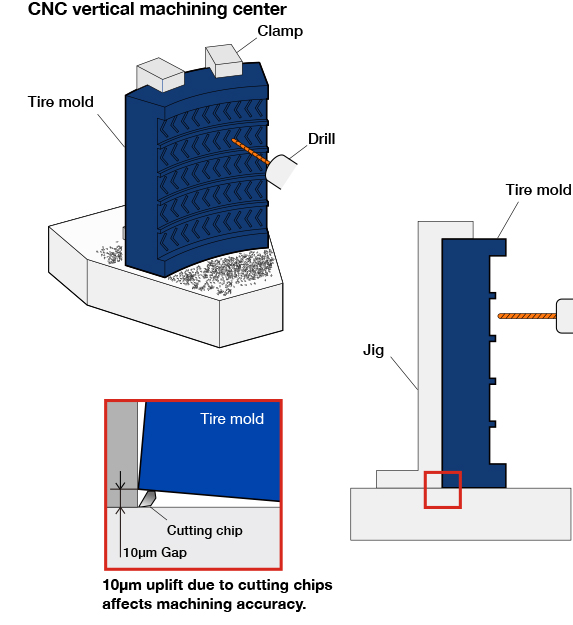

A horizontal CNC machining center was used for milling tired molds;

however,

improperly clamped molds have caused problems with poor machining.

Cutting chips from dry machining can become stuck between the mold and jig bottom when clamping the tire mold in the jig, causing the mold to float up.

Minor gaps of 10μm can majorly affect machining accuracy.

In particular, tire molds are extremely expensive so poor machining cannot be tolerated.

We received an inquiry looking for a sensor that can consistently measure the 10μm gap between the jig and mold, having heard about our sensor at the INTERMOLD die and mold technical exhibit.

The main focus of the issues

10µm gap between the jig and mold shold be detected.

Metrol’s suggestions

Mold milling requires high accuracy, but cuttings or foreign matter can become caught even in the 10μm gap between the mold and jig, causing machining errors that result in large losses.

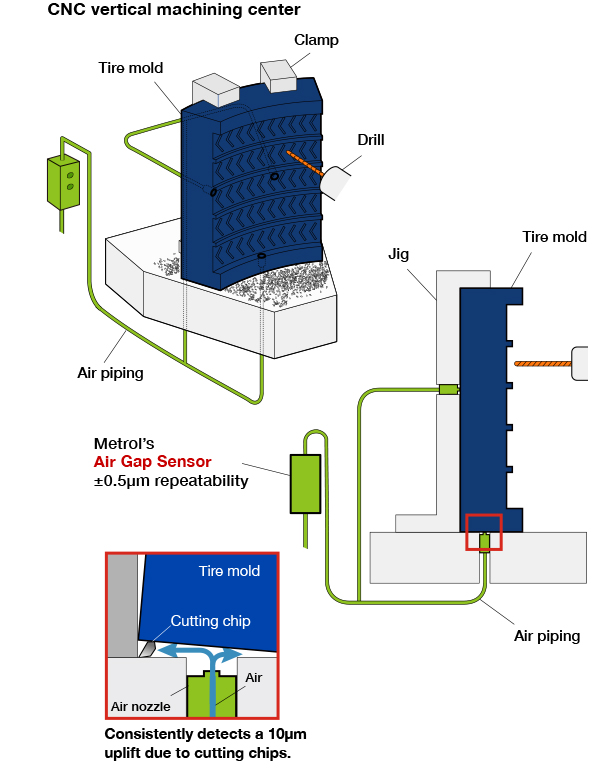

Metrol's "Air Gap Sensor [Short range detection type]" can consistently detect the 10μm gaps caused by cutting chips from dry machining without making contact with ±0.5µm repeatability.

Confirmation of the seating of the mold and jig prevents machining errors due to cuttings, achieving ultra-accurate machining of tire molds.

In addition, the sensor is resistant to harsh working conditions due to the IP67 protective structure and can be installed to horizontal machining centers where cutting chips or coolant splatter.

Improvements

Machining errors can be prevented by detecting 10µm gap caused by cutting chips.

Comment from Metrol representative

“Precision seating confirmation” is essential for CNC machine tool to exhibit its high machining accuracy.

Like the cases introduced here, "Air Gap Sensors" have been widerly adopted by automobile manufactures that require a high-accuracy "machining of the hybrid engine" or "turning process of ABS components".

If you have any troubles with defective products on CNC lathe caused by cutting chips, do not hesitate to contact us.

For further information about the products used in this application

Air Gap Sensor [Short range detection type]

10μm gap caused by foreign materials can be detected with contactless switches.

Precision seating confirmation of jig and workpiece can be realized.