A replacement of the microswitch prevented the double feeding of labels

Printing machine industry

The client is a printer manufacturer that produces label printing presses.

A representative of the label feed unit consulted us on "detection of double label feeding."

Table of Contents

Client’s Issues

The client has been having problems in double feeding when printing the labels.

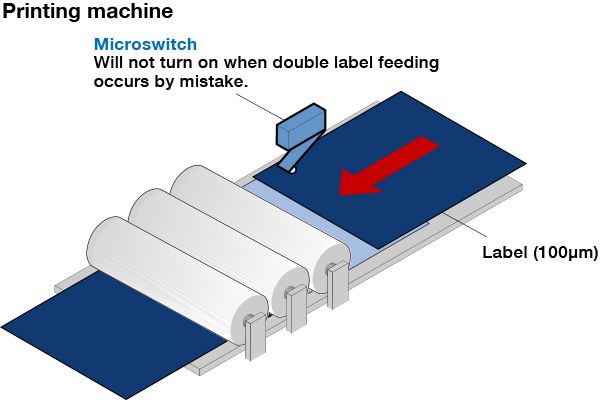

"Microswitch" has been used to detect the number of labels, howeber, the labels are so thin (100µm) that the sensor cannot detect stably.

Although high precision "displacement sensor" or "ultrasonic sensors" were considered, they are so expensive.

The client contacted us through our website looking for a high-precision sensor that can detect 100µm-thick labels.

The main focus of the issues

"Microswitch" is not capable of detecting double feeding of 100µm-thick labels because of the low accuracy.

Metrol’s suggestions

Many engineers think that contact switches like “Microswitch” or “Limit switch” are not suitable for detecting thin labels because of the low accuracy.

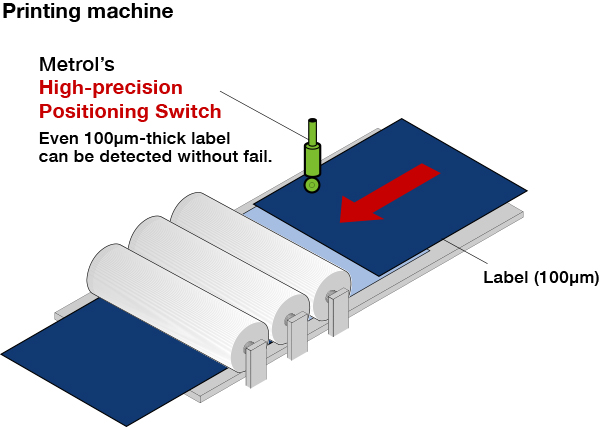

Although Metrol’s “Precision Positioning Switch” is contact type mechanical switch, it contains a uniquely developed switch structure and can demonstrate 0.5µm repeatability.

Double feeding of 100µm-thick labels can be prevented with its tip contact changed to a roller bearing.

Improvements

Double feeding of 100µm-thick labels can be detected by using "High-precision Positioning Switch."

Comment from Metrol representative

"High-precision Positioning Switches" have been introduced widely in the printing industry for the detection of 50µm or thinner sheets and their take-up check.

If you have any trouble with sheet thickness detection on printing machines, please feel free to contact us.

For further information about the products used in this application

High-precision Positioning Switch [MT]

0.5µm in repetetive accuracy.

Realize precision detection of double label feeding.