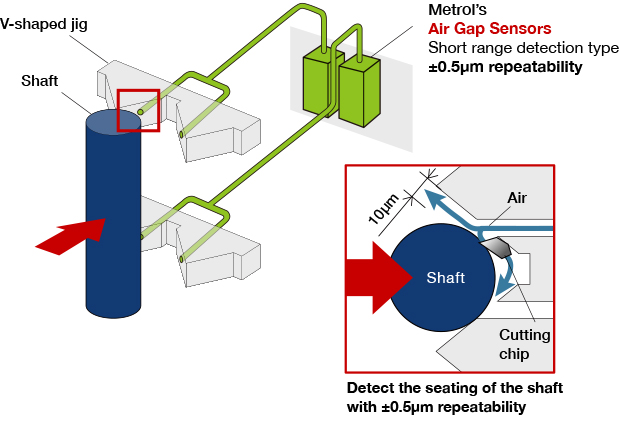

Prevents defective products by detecting seating of the shaft with ±0.5µm repeatability

Precision machining industry

A precision components manufacturer that produces shafts for automobiles.

A representative of the engineering department consulted us on “seating confirmation” of the shaft and jig.

Table of Contents

Client’s Issues

The client has a trouble with cutting chips put between the shaft and jig when clamping the shaft in V-shaped jig in machining by CNC horizontal machining center.

A air sensor was used to detect the seating of the shaft, however, because of the low repeatability of 20µm, the uplifts by 10µm cutting chips cannot be detected stably.

A 10µm slight uplifts caused by cutting chips result in defective products.

He needed a non-contact air sensor that can detect the seating with good accuracy and inquired us after sales representative visited him for PR.

The main focus of the issues

A 10µm slight uplift by cutting chips should be detected.

Metrol’s suggestions

Accurate workpiece seating confirmation is important to prevent defective products before machining.

However, most of “air sensors” adopted on machining centers as standard equipments are intended for “existence detection” of workpieces and not suited for “precision seating confirmation.”

Metrol’s “Air Gap Sensor short range detection type”, on the other hand, is the non-contact type air sensor containing a uniquely developed pneumatic circuit.

It can demonstrate 0.5µm repeatability which is more than 10 times as precise as that of conventional air sensors and detect the uplifts due to cutting chips stably.

Defective products can be prevented by realizing accurate seating confirmation of the shaft and jig.

Improvements

A 10µm slight uplift caused by cutting chips can be detected reliably.

Defective products can be prevented.

Comment from Metrol representative

“Air sensors and gap sensors used in the machining centers are not capable of precision seating confirmation because of low accuracy."

“Defective products should be prevented in the machining process…”

Metrol’s ”Air gap sensor" introduced here was developed in response to such demands.

If you have any trouble with the low accuracy of your air sensors and gap sensors, please feel free to contact us.

For further information about the products used in this application

Air Gap Sensor [Short range detection type]

±0.5µm repeatability!

Capable of checking the precise seating of workpieces and jigs, making ultra-accurate machining with CNC machine tools possible.