[Thorough Explanation] High Precision Touch Switches That Can Be Easily Customized In Only 10 seconds!

Dear designers and production engineers, have you ever had this problem?

- Want to use the best sensor for the equipment, other than an expensive custom-made sensor

- Want to use low-cost, high-precision sensors

- Can't find the right sensor that fits the design perfectly

When designing equipment and jigs, it is difficult to find parts and sensors that exactly match the application and conditions.

Requesting custom-made products is expensive and time-consuming.

This article introduces the P10DH series of high-precision touch switches, which can be customized quickly and inexpensively by the user.

The main points of this article

- What is a touch sensor that can be easily customized at low cost and in a short time?

- Know how to select and procure sensors and customized parts

What is METROL’s precision positioning touch switch that increases equipment productivity and accuracy?

Table of Contents

What is the “P10DH Series” of customizable sensors?

- ”Micro-switches don't work under the conditions."

- ”I want to know a high-precision sensor that is perfect for my design."

- ”I want a touch switch with a spherical tip contact."

METROL receives a variety of requests for customization of touch switches on a daily basis.

In recent years, however, user issues have become more diverse, and there are cases where positioning touch switches from catalog products are not sufficient.

Therefore,

We have developed the "P10DH Series" of touch switches that allow users to customize their own contacts.

The following video explains what kind of switch is the "P10DH series". (Time: about 60 seconds)

Normally, METROL's touch switches have a fixed contacting parts (measuring element) on the end of the switch that touches the object to be detected.

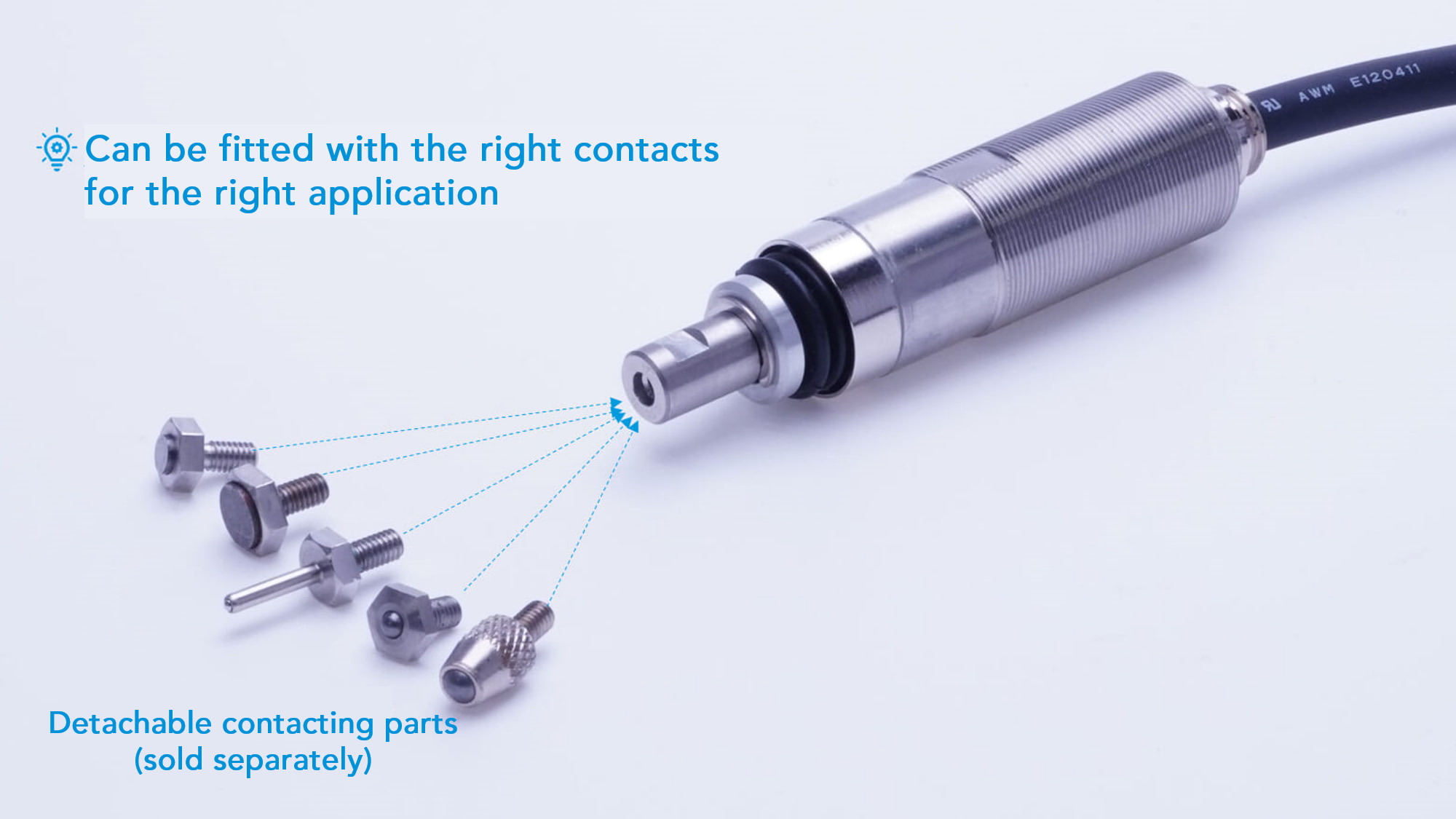

The P10DH series has an M2.5mm threaded hole instead of the absence of a "tip contact " and can be equipped with a contact of your choice.

(see image 1)

By attaching a contacting part of your choice to the touch switch, you can use it in the most suitable form for your application.

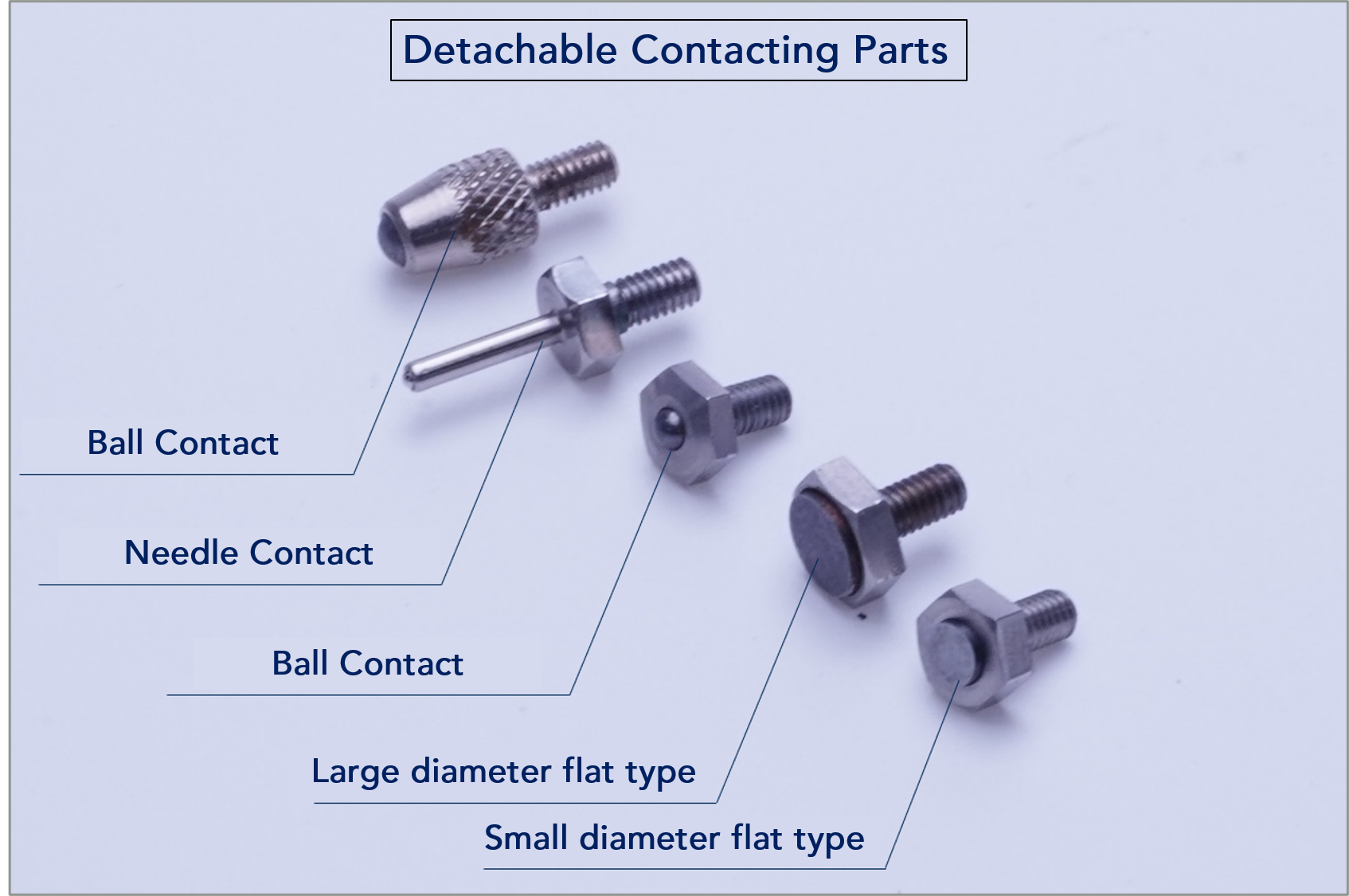

Below are 6 examples of various contacts worn.

When is the P10DH series beneficial?

The contacting part itself can be obtained inexpensively.

- I want to try different contacting parts while designing equipment.

- Instrument specifications have changed and the measurement device has to be changed.

P10DH will work well in the above situations.

Among other benefits, the P10DH series also contributes to cost reduction.

Even if the contact is damaged, it can be used for a long period of time by replacing only the contacting part without having to purchase a new switch body.

Basic specifications of the P10DH series

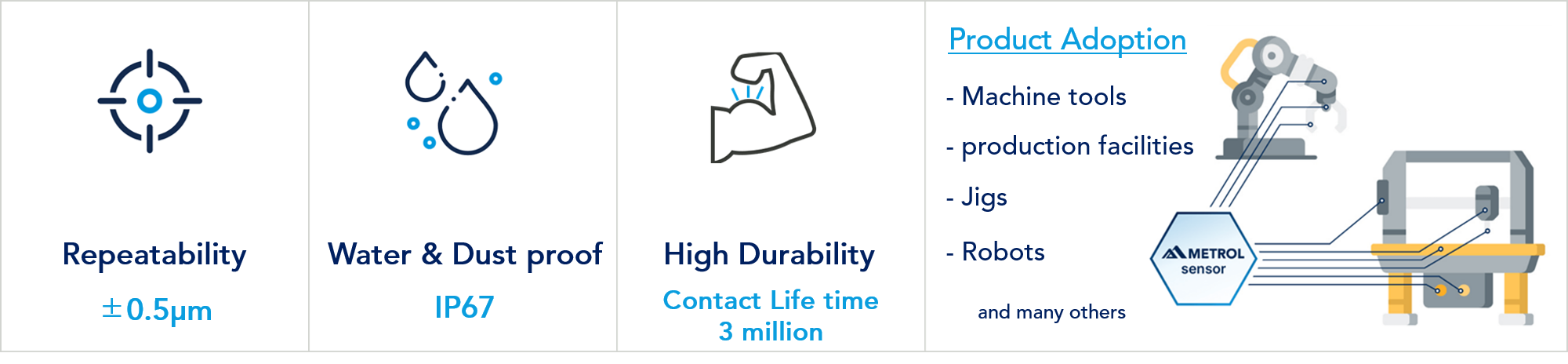

Furthermore, the basic functions of the P10DH series offer the highest level of Durability and Accuracy among positioning touch switches, including micro switches and limit switches.

- Repeatability of 0.5μm(the highest level of accuracy in the series)

- Waterproof mechanism with protection class IP67 (proven in machine tools)

- Contact life of more than 3 million cycles

They are used in many high-precision positioning for machine tools, automatic machines, robots, conveying equipment, and various other equipment that use water or oil.

Coolant (cutting oil) durability test

The P10DH series is used inside machine tools and has a protective structure to withstand direct coolant injection.

(See video)

Glossary: What is a “Contacting part”?

The measuring element (=contact) is the part that the touch switch contacts when it detects an object to be detected.

These parts are familiar mainly with dial gauges.

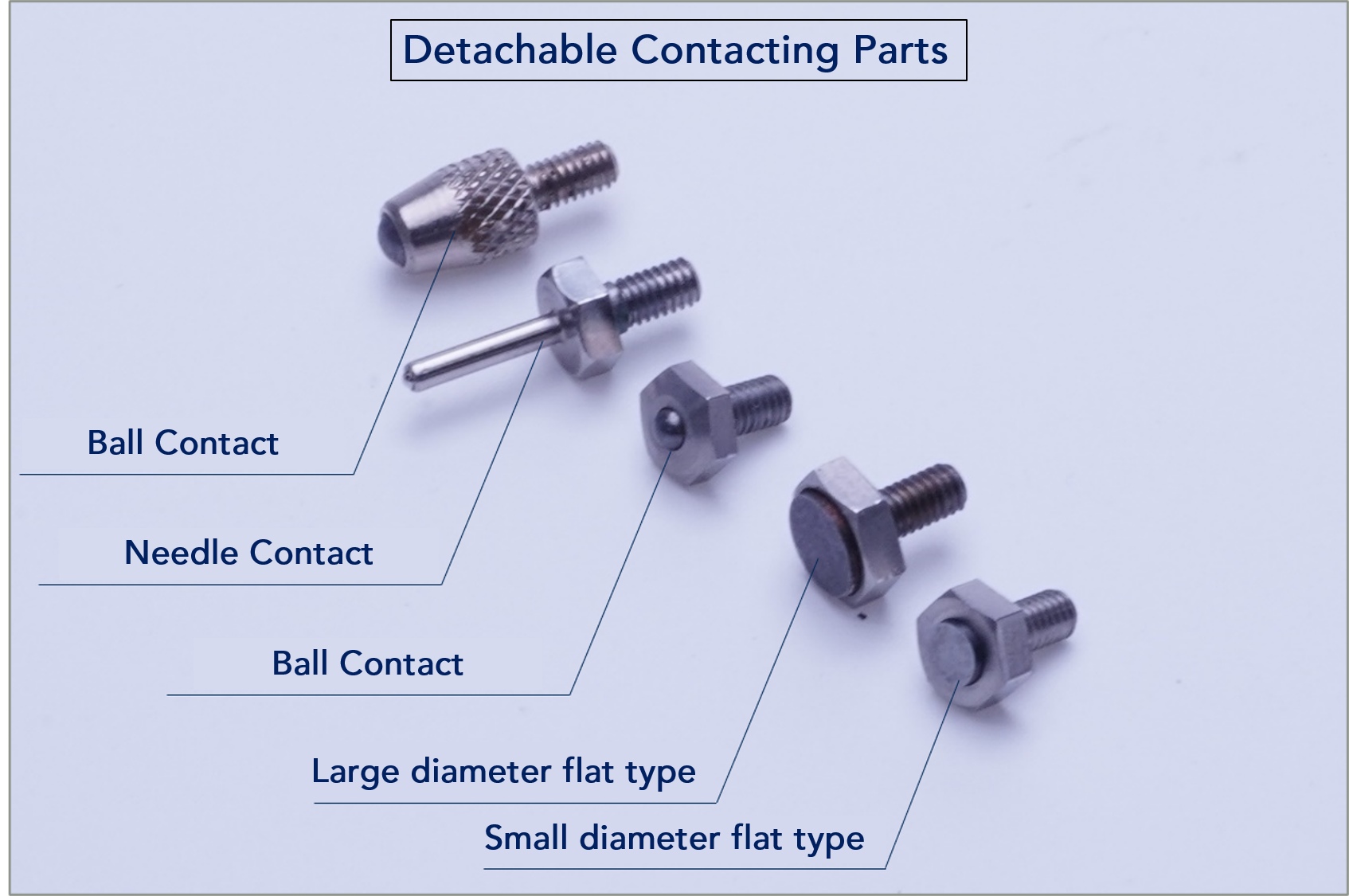

In general, there is a wide variety of measuring elements in terms of diameter size, shape, and material.

It is an important part when selecting a switch because it is used depending on the location where it is used and the workpiece to be detected.

Can also be used as a single-axis touch probe

The P10DH series can also be equipped with a stylus for touch probe and can be used as a single-axis touch probe.

It can also be applied to cases where it is mounted on equipment such as grinding machines and 3D printers to detect only the Z-direction, such as the height dimension of a workpiece.

How to Select a Contacting part by Type

The P10DH series comes with an M2.5 threaded section, and it is essential to select an appropriate contacting part".

For example,

- If you want to detect the bottom of a narrow hole, you need an elongated "needle-shaped" contacting part.

- If you want to hit the workpiece from an angle, you can use the "R shaped" contacting part.

- If the workpiece is to be detected by sliding the switch from right beside it, a "ball-type" contact part is needed.

- If you want to detect two sheets of paper in your paper feeder equipment, then the "Roller type" is for you.

Examples of commercially available contacting parts

Although not handled by Metrol, roller-type measuring elements and other products are available on commercial e-commerce sites. They are used for detecting double sheets of paper in paper feeders, etc.

How to Select a Contacting Part by Shape

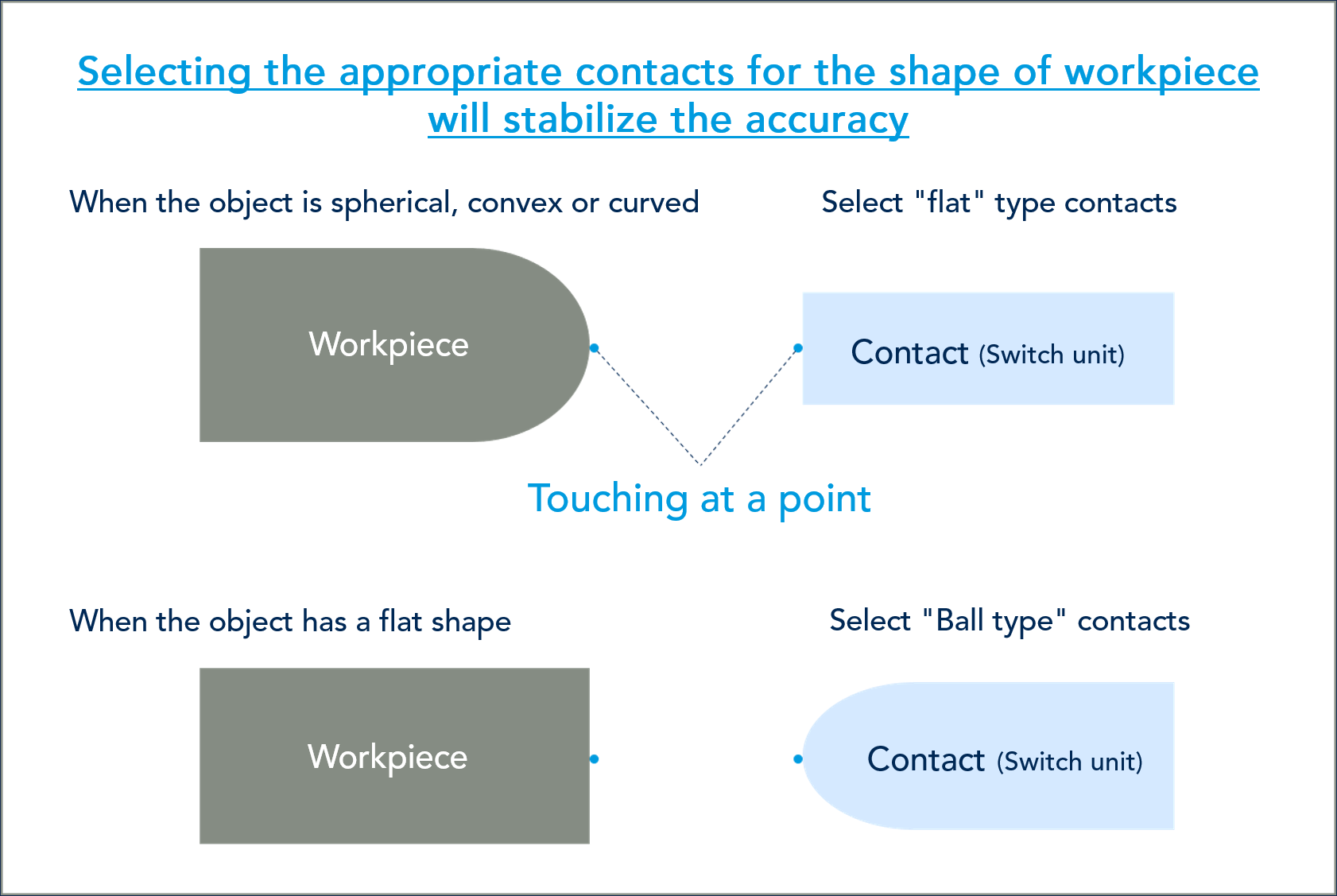

If an appropriate contacting part is not selected depending on the shape of the object to be detected, inconsistent accuracy can occur.

Basically, the relationship between the object to be detected and the shape of the contact is a combination of the following

- If the detected workpiece is "R shape", then "flat contact".

- If the detected workpiece is a "flat shape", then "R shape contact".

Note that accuracy is not stable when planes or R shapes contact each other.

Three ways to procure contacting parts

The "P10DH series" main unit does not come with a measuring device, which must be prepared separately.

There are three main ways to prepare a contacting part.

- Select from the METROL catalog

- Purchase a commercially available measuring device from another company.

- Users fabricate their own measuring elements.

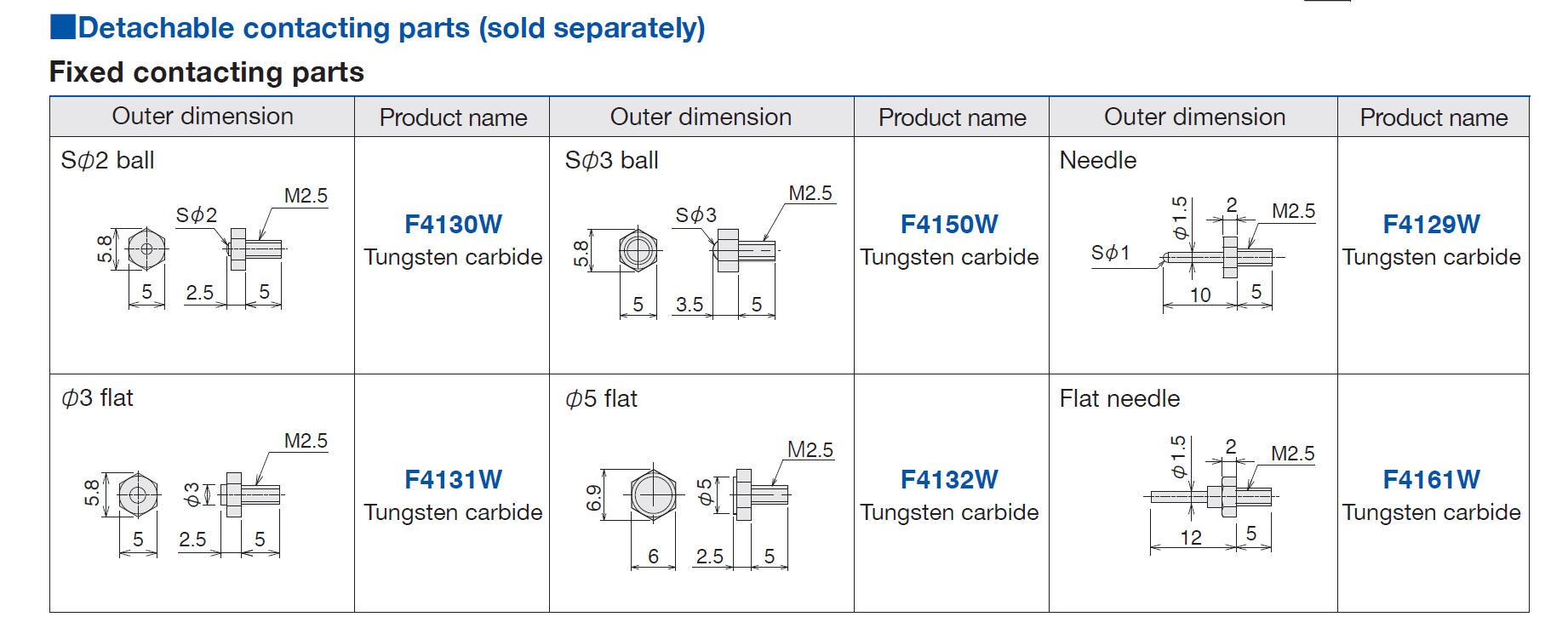

Procurement Method 1: Select from the METROL catalog

There are 12 types of contacting parts hat METROL sells as standard products in its catalog.

You can choose from pages [3-19] of the catalog.

Of course, METROL can also design and manufacture special products even if they are not listed in our catalog.

Please feel free to contact us.

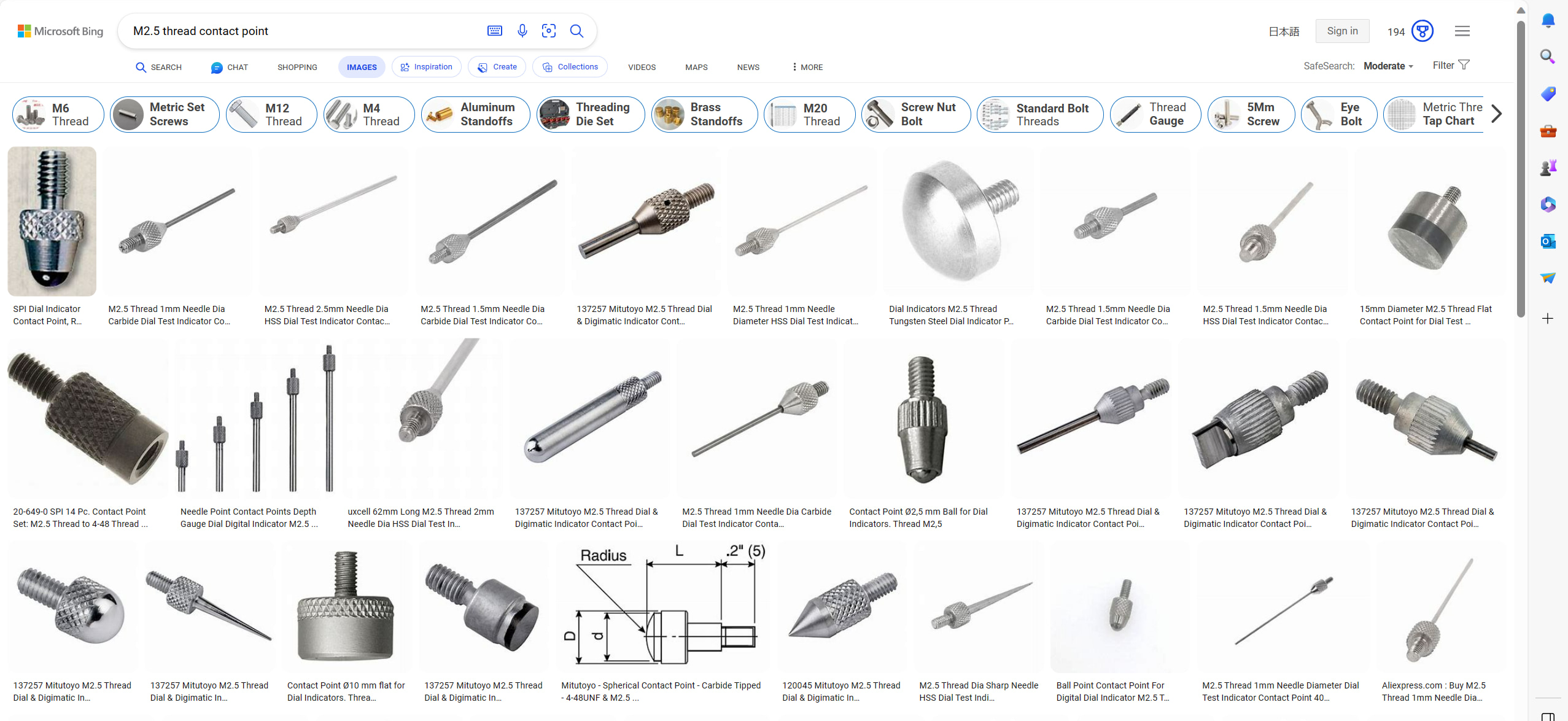

Procurement method 2: Purchase a contacting part made by another company

A search for "M2.5 contact point" on the Internet turns up a large number of contacting parts made by other companies.

There are also many specialized contacting parts for various applications, which can be selected here.

Procurement method 3: Users manufacture their own measuring elements

If you cannot find suitable contacting parts for your purpose, you can make it yourself.

In fact, many users have adopted the "P10DH series" customized by manufacturing their own measuring elements on their machine tools.

If the shape of the measuring element is special, or if you need to control tolerances and quality in-house, we recommend that you make your own.

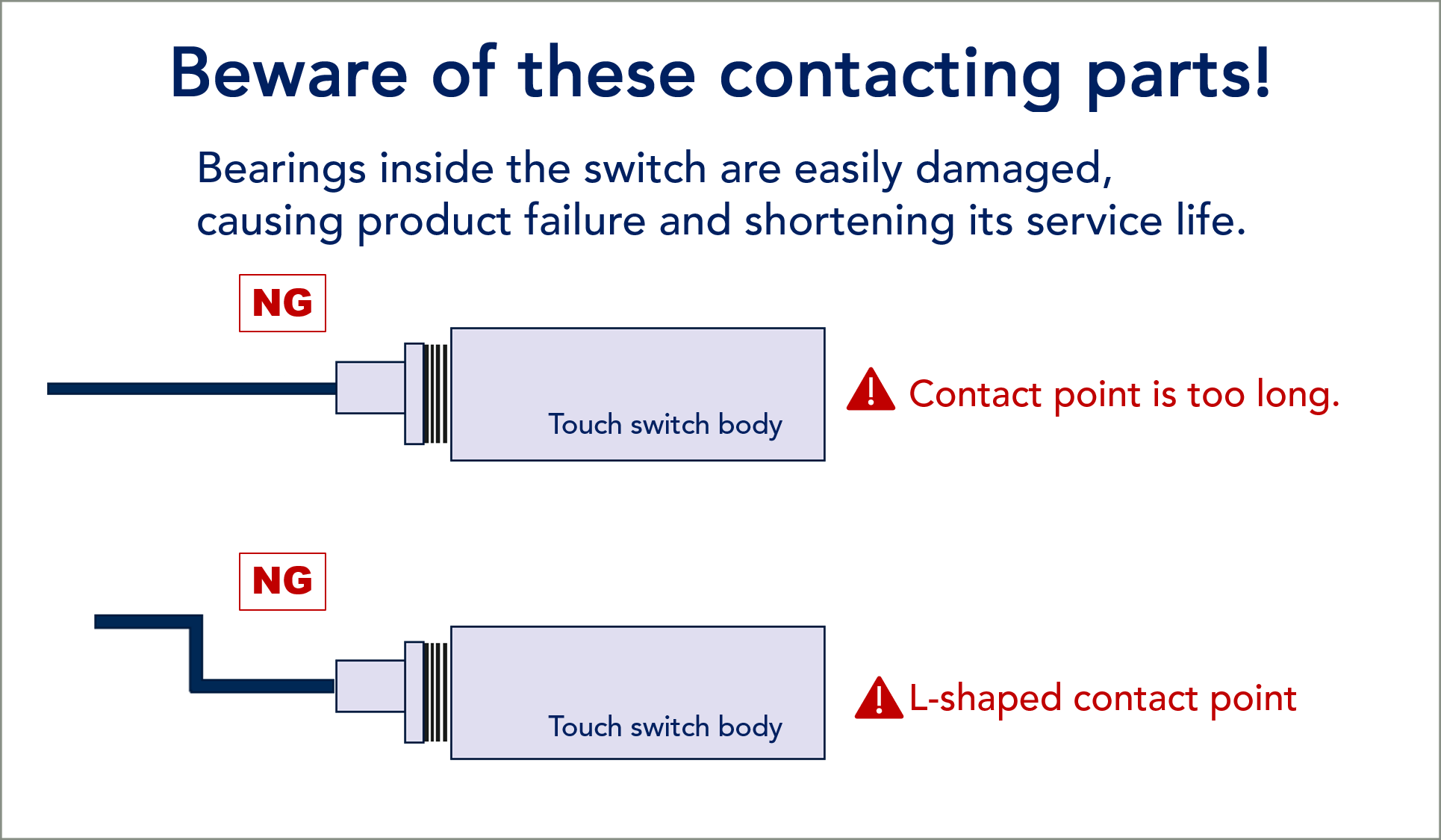

Beware of these contacting parts!

Using a contacting part that is too long or an L-shaped (offset), etc., may put a load on the bearing, resulting in a lack of guaranteed accuracy or risk of damage. The touch switch is structured so that the measuring element is pushed in by a linear bearing (ball bearing) and outputs an on/off signal.

Repeated contact without taking this structure into consideration will put a strain on the bearings and contacting parts, which will affect the life and accuracy.

Conclusion: Features of contacting point Customization [P10DH Series]

- M2.5mm contacting parts can be freely customized.

- In-house designed or third-party contacting parts can be combined

- Low cost due to a replaceable contacting part only, even if it is deteriorated.

- Repeatability ±0.5µm, protection class IP67 for high accuracy even in environments exposed to oil or water

METROL's original "P10DH series" touch switches, which allow flexible customization of the contacting parts.

The advantage of being able to replace only the contacting parts has been well received by many users in terms of cost.

If you are a designer who wants to incorporate a touch switch that fits your own design at a low cost, please share this information within your company.

METROL can also customize and select other customer-specific touch switches and sensors.

Please feel free to contact us.

Purchase Flow of Touch Switches and Contacting parts

If you would like to purchase this product, please visit this page on our website.

Enter the product number "P10DH" and quantity to request a quote.

Click here to purchase

METROL direct shopping EC site

Other Distributors

Please contact the distributors listed below.

List of Sales Agents

Products mentioned in this article

Contacting parts Customization [P10DH Series]

Touch switch to which an optional contacting parts can be freely attached.

The advantage is that it can be easily customized and parts can be replaced, reducing expensive order-made costs and parts maintenance costs.

![Contacting parts Customization [P10DH Series]](https://metrol-sensor.com/wp-content/uploads/2021/10/MET_D_2_P10DHA_T-3-scaled-1-800x530.jpg)