Overview Of The T24M Series, Next-Generation Tool Setters for Machining Centers Made By Yamazaki Mazak

Table of Contents

Introducing the T24M series – next-generation tool setters with higher precision, productivity and convenience.

To users of Mazak machine tools – are you satisfied with your current tool setters?

In this article, we introduce the T24M series, which is a clear upgrade from current tool setters in terms of precision, durability, and ease of use.

The T24M tool setter series was designed exclusively (custom made) for Yamazaki Mazak Corporation.

Already adopted as an option in Japan and China, this series is being incorporated by many machine tool users who aim for effective and high-precision machining.

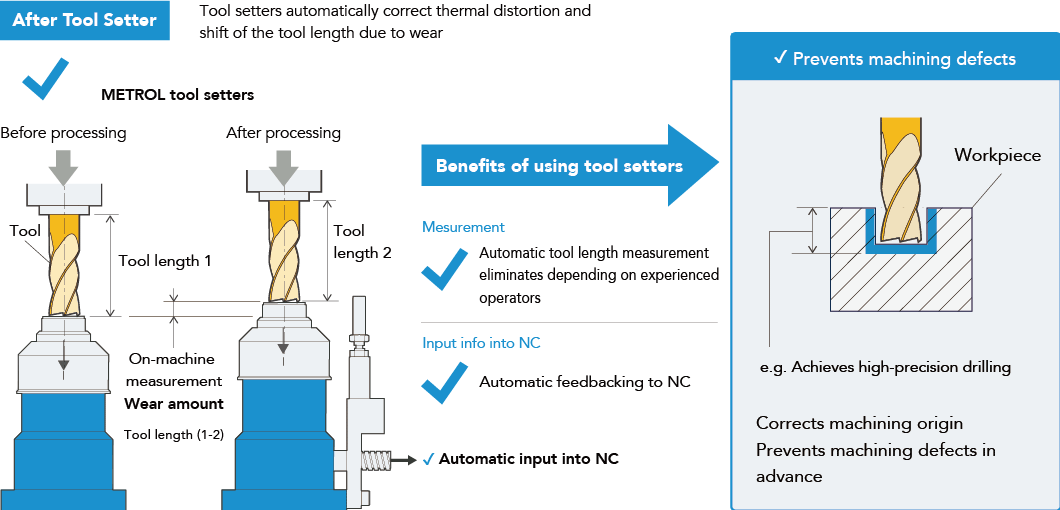

Review: What are tool setters?

Tool setters are mainly contact-type sensors used for measuring tool length at machining centers and other sites.

- Tool breakage detection

- Tool zero point setting before machining

- Correcting thermal variation

Tool setters are used for these and other purposes. Many users are likely already utilizing them.

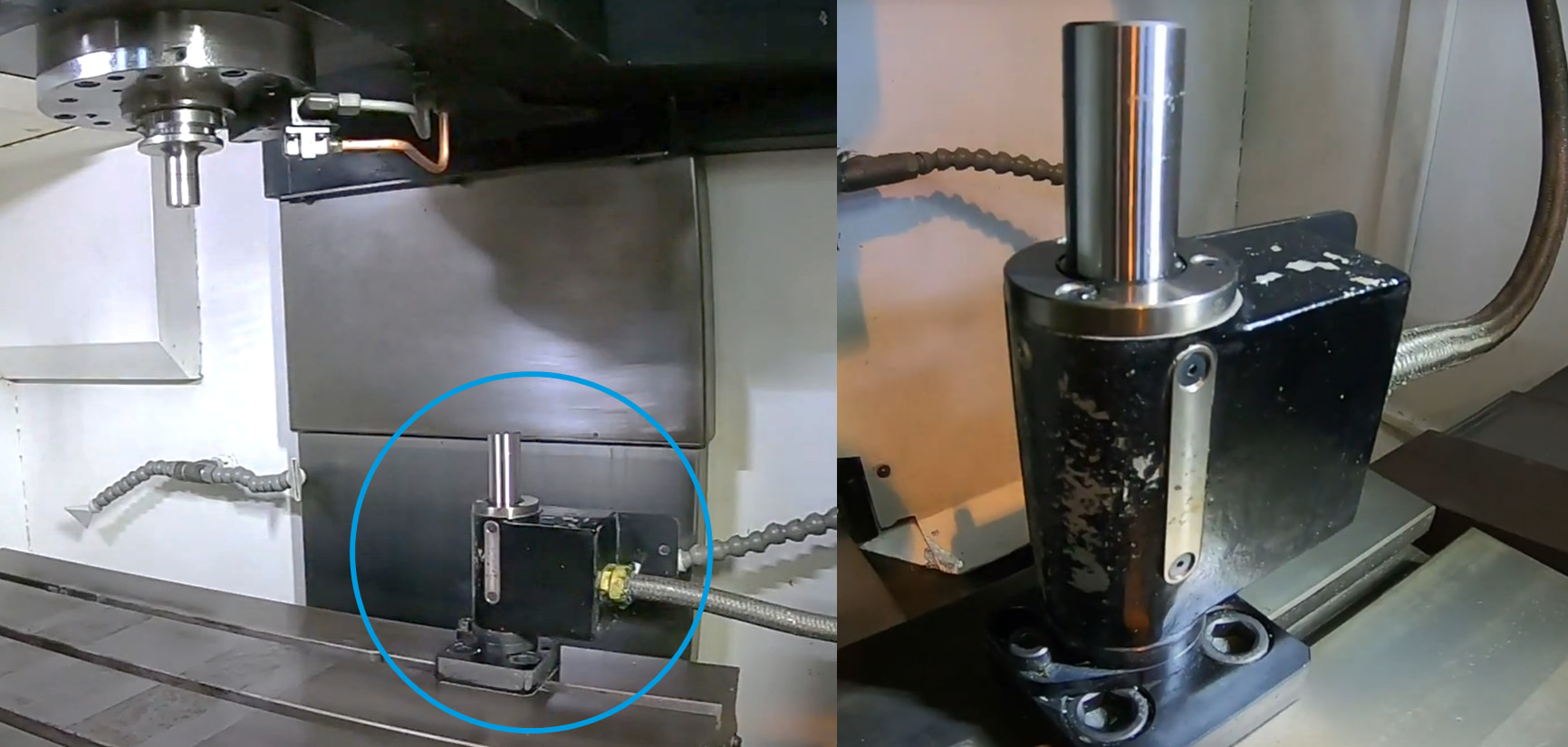

Current genuine tool setters for Yamazaki Mazak.

Genuine tool setters are equipped on many Yamazaki Mazak machine tools.

These official tool setters have basic functions for detecting breakage to the tool length.

Features of current tool setters

There are many users who want higher precision when seeking high-precision machining with a repeatability of 10 µm.

Correcting tool length from thermal variations in machines and handling small-diameter tools are both issues that users deal with, leading them to demand higher precision and more convenient tools.

- Purpose: Detecting breakage in cutting tools

- Repeatability: ±10 µm

- Contact force: 30N

- Total length: 200 mm

- Air blower for chip removal: N/A

- Attachment/detachment: Fixed with a hexagon nut

T24M tool setter series, a new option for Mazak users

Tool setters play an important role in tool length measurement and correction during precision machining.

On the other hand,

- Improving the required precision for metal machining

- Diversifying tools

- Labor saving for setup work / Ease of use of machines

are all examples of users’ needs becoming increasingly diverse. This has also led to demand for “increased precision”, “productivity improvements”, and “ease of use” for current tool setters.

METROL has developed the “T24M series”, next-generation tool setters for Yamazaki Mazak, to meet these needs.

[Option usage] Vertical machining center VCN series

The T24 series is already used as an option for Yamazaki Mazak’s vertical machining center VCN series.

Product features: Evolution point for the T24M series

Here we give concrete explanations, one by one, of which specifications were updated.

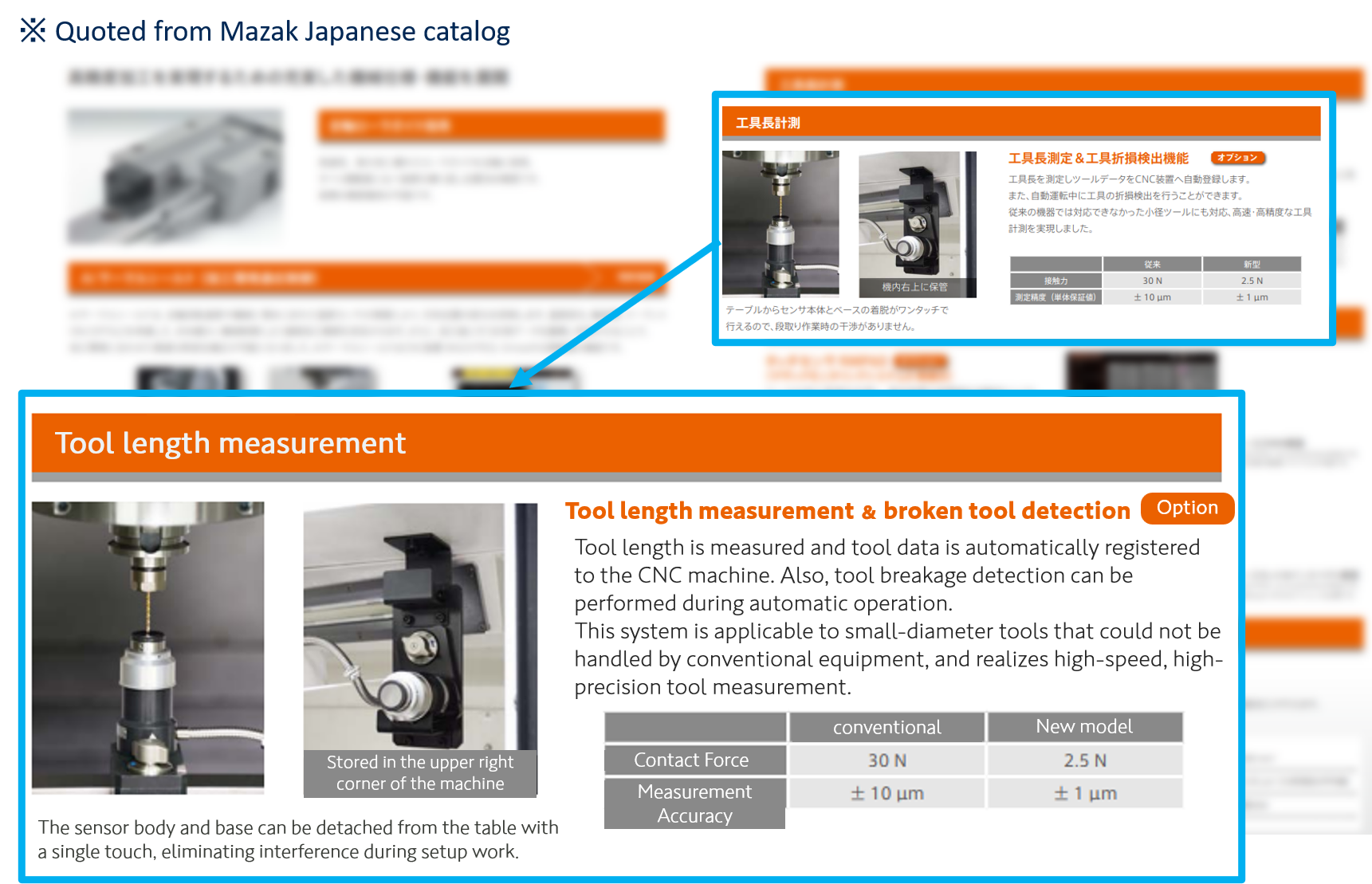

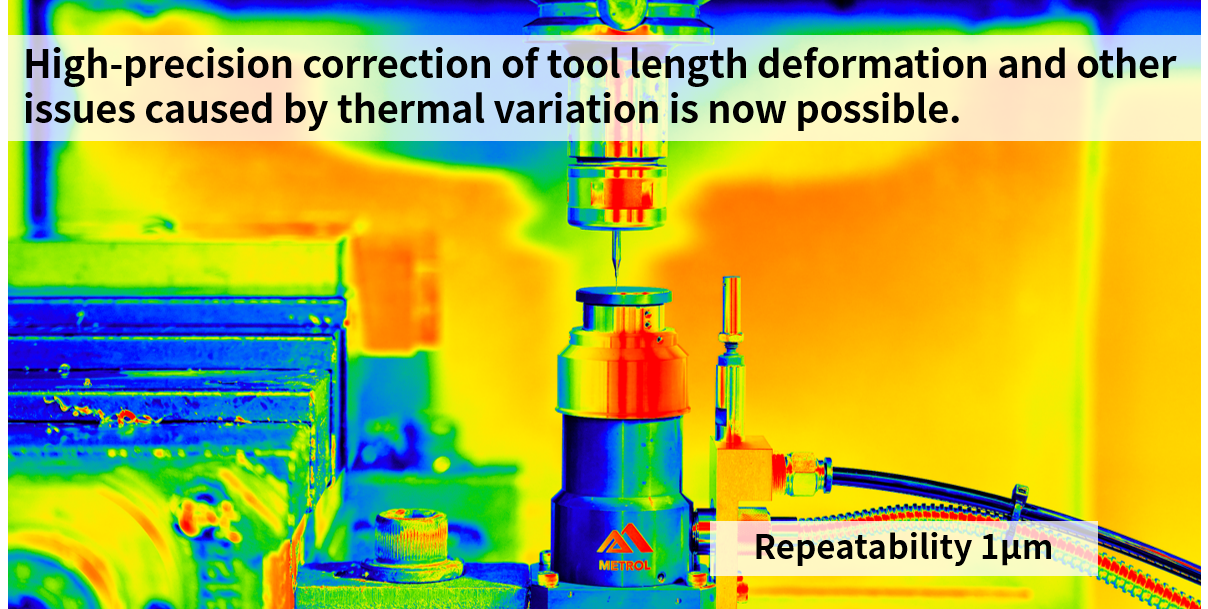

Thermal variation correction possible. 10 times more precise than current products.

Repeatability has been improved by 10 times – from the current ±10 µm to ±1 µm. Tool length deformation caused by thermal variations can now be corrected.

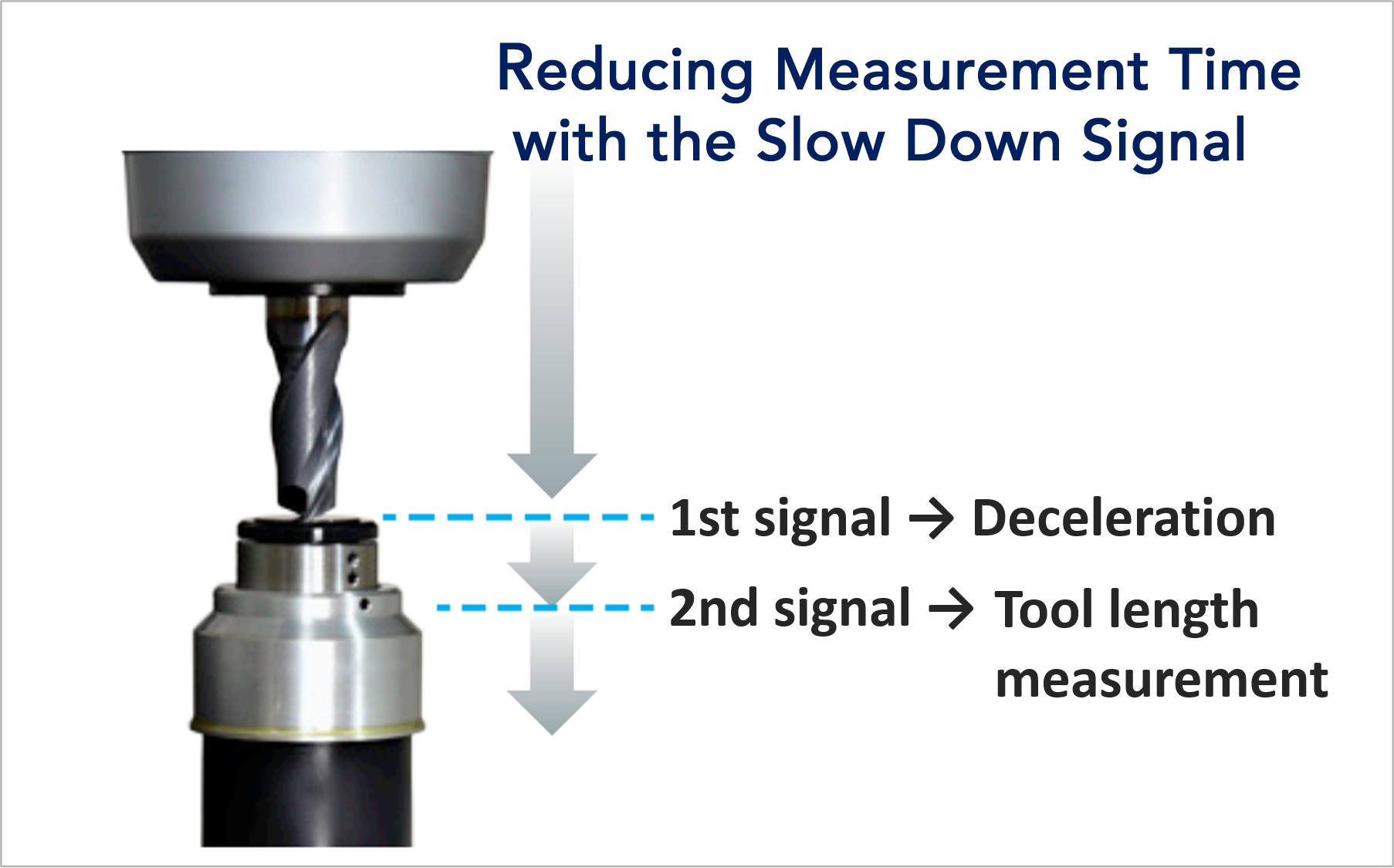

Measurement without reducing productivity, 2 signal functions

Measurement without compromising productivity is now possible, thanks to the 2 signal functions of deceleration signals and tool length measurement.

With the 1st signal – deceleration signal – users can inspect the tool length without damaging the sensor even if the tool touches the sensor at high speed.

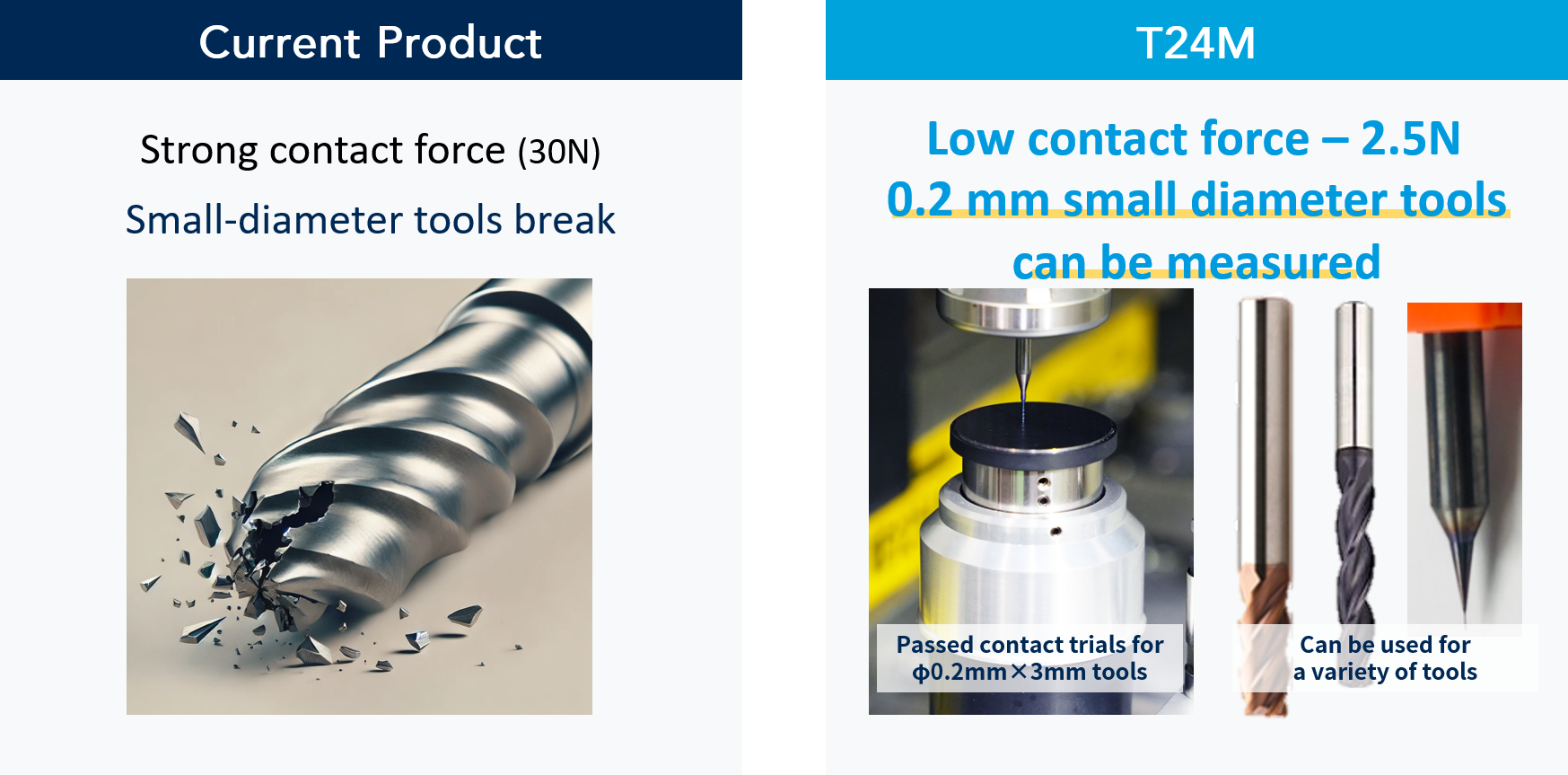

Low contact force that enables measurement of small-diameter tools

The contact force needed to operate the sensor is reduced from the current 30N to 2.5N – a nearly 80% reduction, allowing for measurement of a wide range of tools, including small-diameter tools.

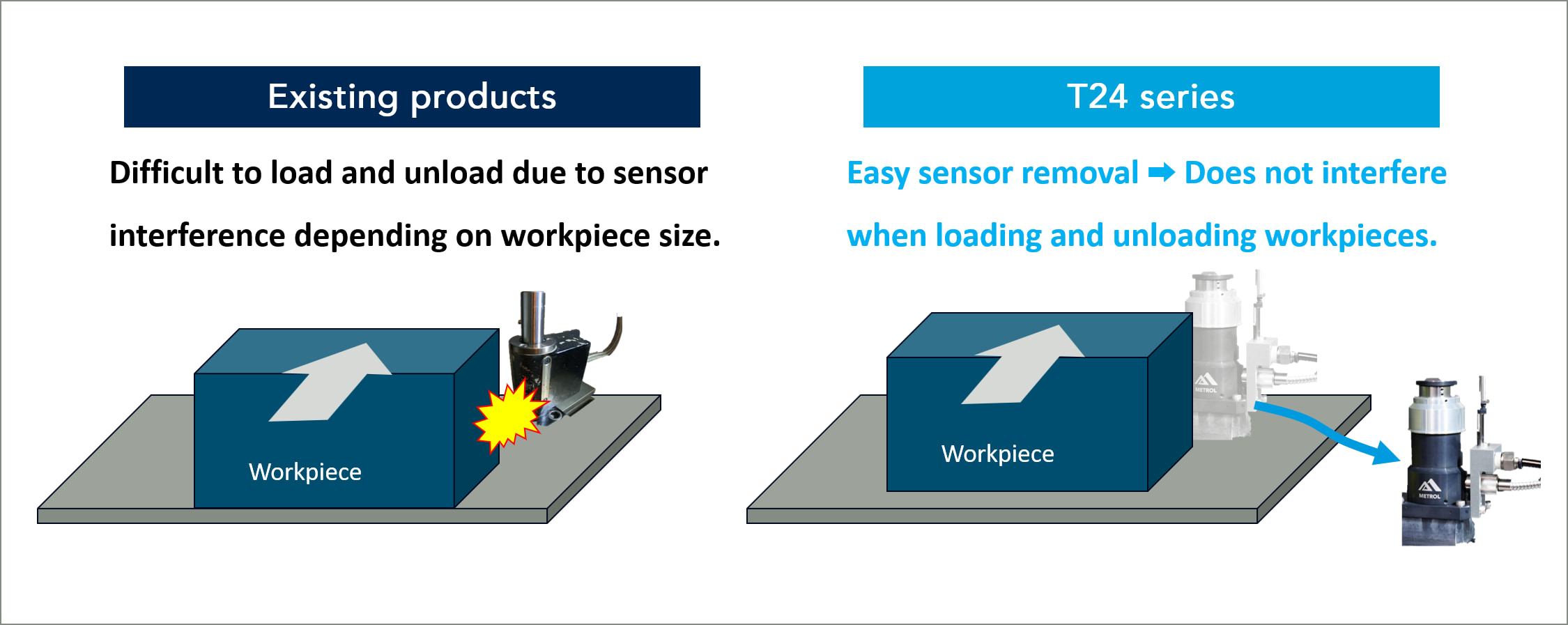

Single press removal possible (single-press clamp function)

Thanks to the single-press clamp function, users can remove the sensor in one motion when loading and unloading large size workpieces that interfere with sensors and workpieces.

Preventing erroneous detection due to chips: Air blower function

The T24 series is equipped with an air blower, a feature not included in existing tool setters.

The air blower can prevent erroneous detection by removing chips and coolant liquid on the contact surface that detects the tool.

Passed strict durability trials: Extremely waterproof and durable

IP67 specifications that have undergone high-load durability trials and waterproofing trials. Can be used for long periods even in a coolant environment.

Please see the durability trial video.

Connector specifications that allow for easy sensor replacement

Even if the sensor is broken, users can remove the connector and replace just the body.

Cable wiring work and other tasks also take no effort at all.

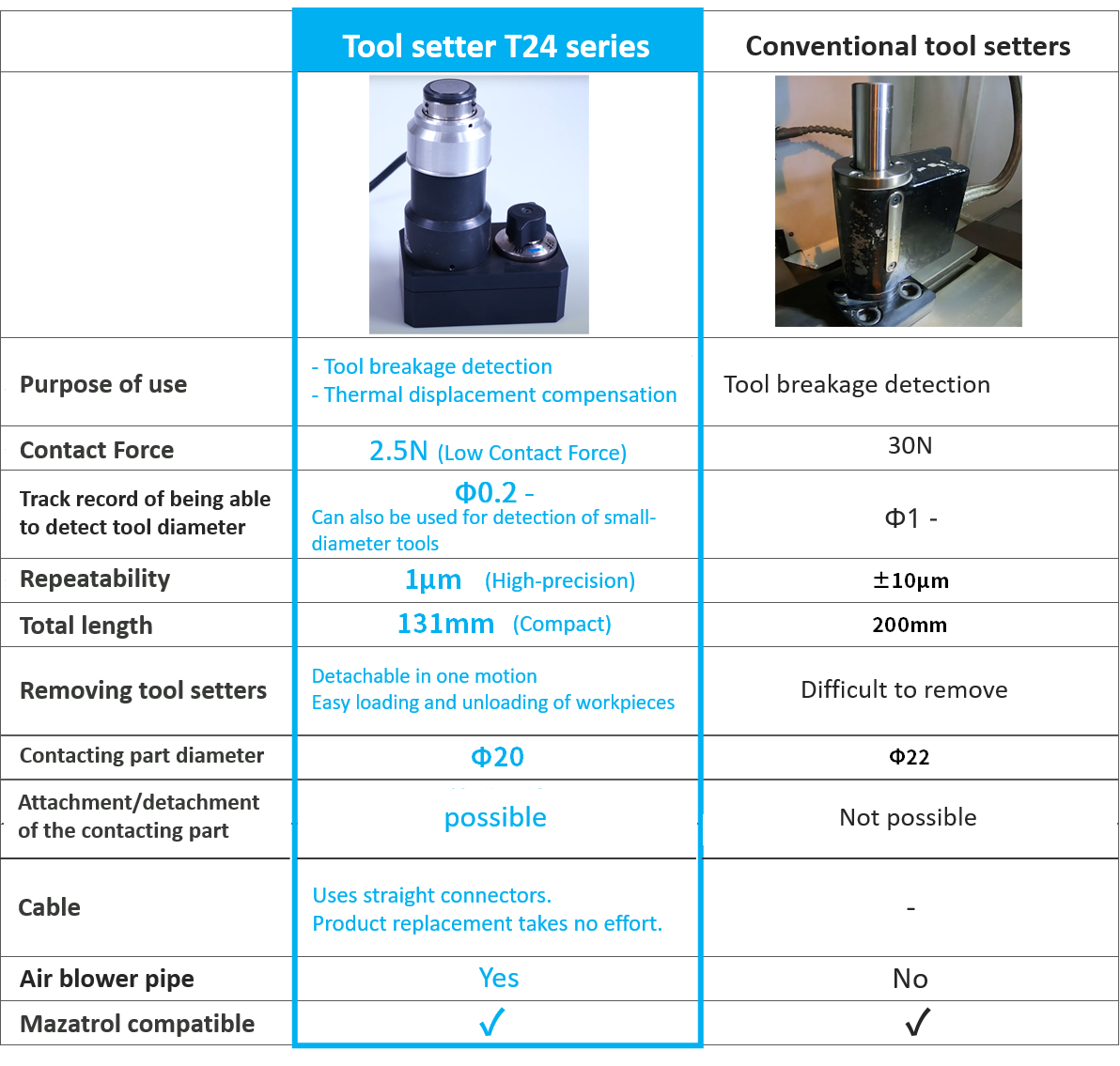

Summary: Comparison of current products and T24 series

Compare specs for current tool setters and the T24M series exclusively designed for Yamazaki Mazak and you’ll find the following differences.

The T24 series does not just improve precision – it updates specifications that are useful for machine tool users in various aspects, including improving productivity and usability.

Interested users should inquire with machine tool makers or with METROL.