Story of Made in JAPAN Vol.2 ~Sensors for CNC Machine tools~

Table of Contents

Do you know the machines called “mother machine”?

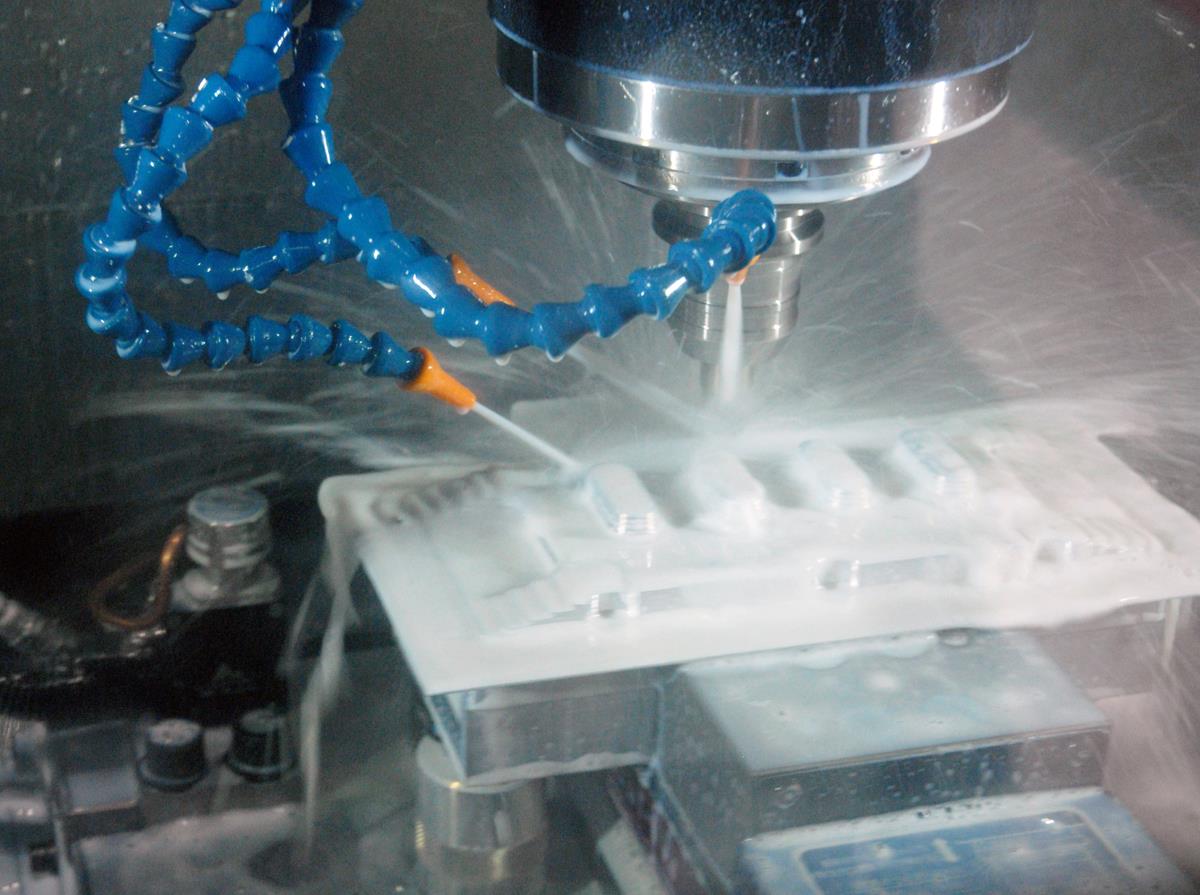

"Machine tools" used to cut metal parts and molds of cars, cellular phones or cameras are called "Mother Machine".

There are various kind of tool machines, such as machining centers, lathes, milling machines and so on.

All of these tool machines are required to have the machining accuracy in micron level.

In order to achieve the machining accuracy, measuring a length of drill is essential.

Tool length is subjected to change every day – because of the tool wear after machining and temperature difference throughout the day.

However, it is extremely difficult to measure the tool length in microns under harsh environment, where metal chips and coolants spatter all over.

And that is where Metrol “Tool setters” come to the rescue!!

Even 1 micron (1/1000mm) of Tool wear can be detected, which can be updated for achieving high machining accuracy.

Metrol Tool setters have been chosen by Machine Tools Builders in more than 17 countries around the world, and over 500,000 units are now used regularly in order to support the World's "Mother Machines".