Story of Made in JAPAN Vol.3 ~Air Micro Switch~

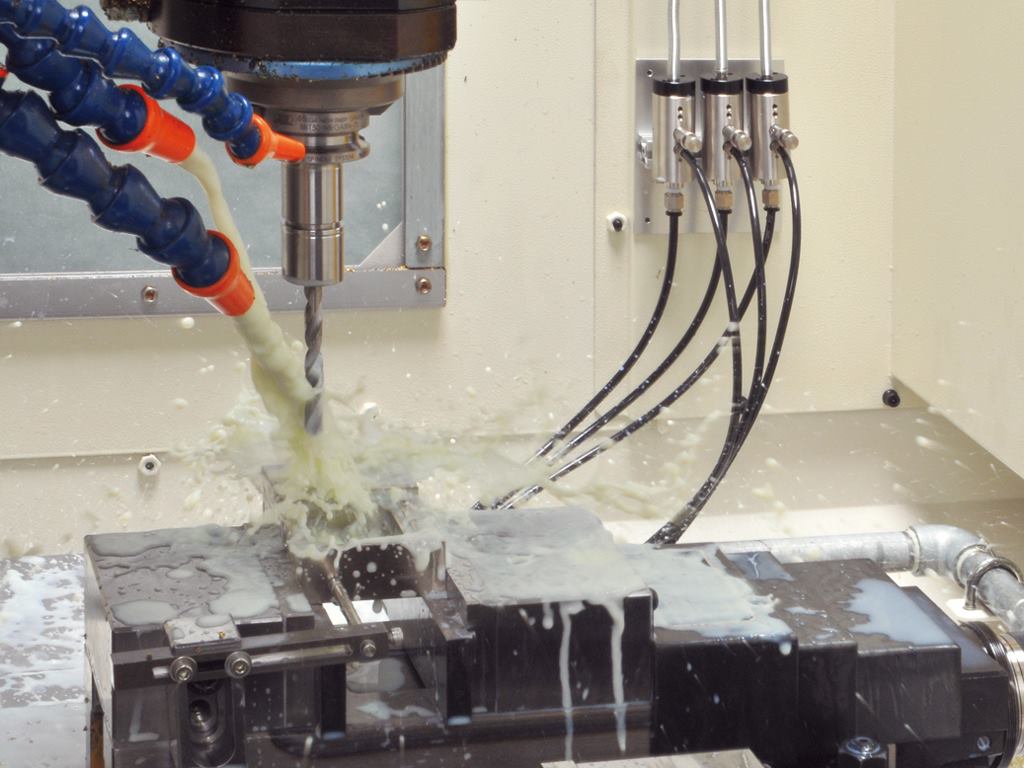

This high-precision Metal Cutting work represents one of the Japanese "Monozukuri*" industries where Metrol's technology plays a vital role behind the scenes.

*Monozukuri is the Japanese term to express Zen Art of Design and Manufacturing of product.

To produce precision Automobile components, it requires accurate positioning of the workpiece in the chuck and fixtures.

Yet, inside the Machining and Turning Centers where metal chips scatter all over, there have been product failures due to small chips being caught in between the workpiece and chuck; which results in the component having different dimensions than what was originally designed in the CAD model.

Table of Contents

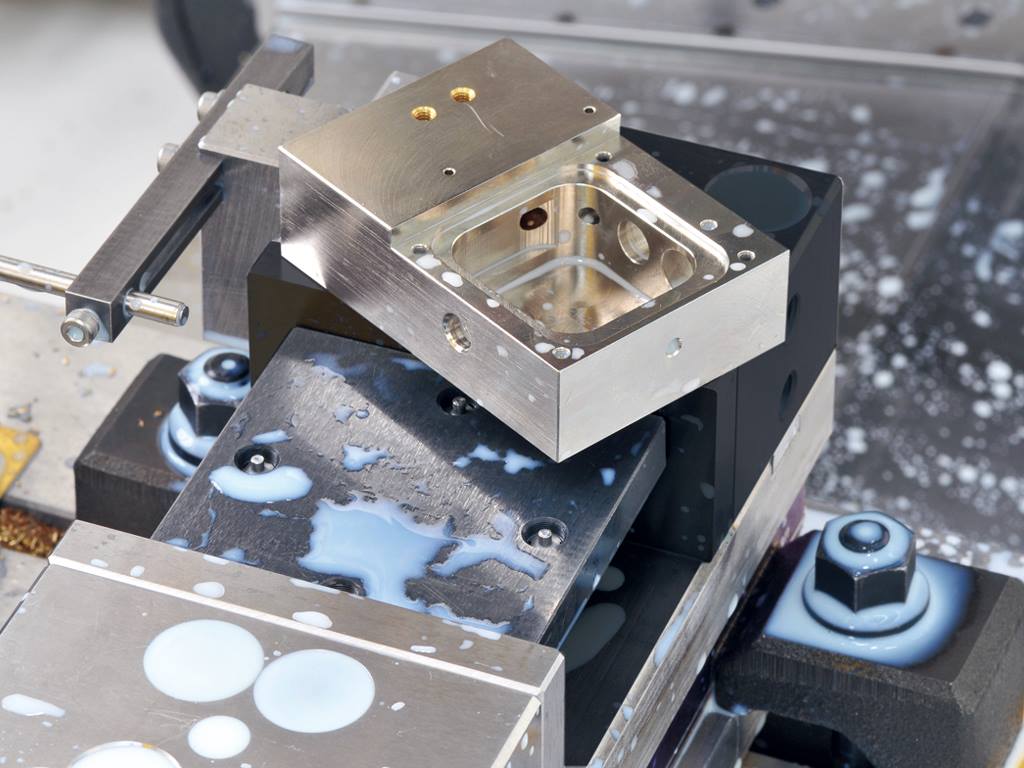

And that is where Metrol “Air Microswitch” come to the rescue!!

Using the changes in air pressure, Metrol Air Microswitch detects even the tiny gap of 2 micron gap between the workpiece and chuck.

The “gap” is only 0.002 mm!

Detection of slight gaps as small as 1/50 of human hair supports manufacturing of Japanese high performance "automobiles".

Feel Free to contact us if you have any questions about our products and technical inquiries.

Our experienced engineers will be more than happy to assist you.

+81 50 5558 7366

Monday - Friday 8:30-17:30 JST.

+81 42 528 1442

Write down your questions