Story of Made in JAPAN Vol.4 ~Touch Switches in Manufacturing Scenes~

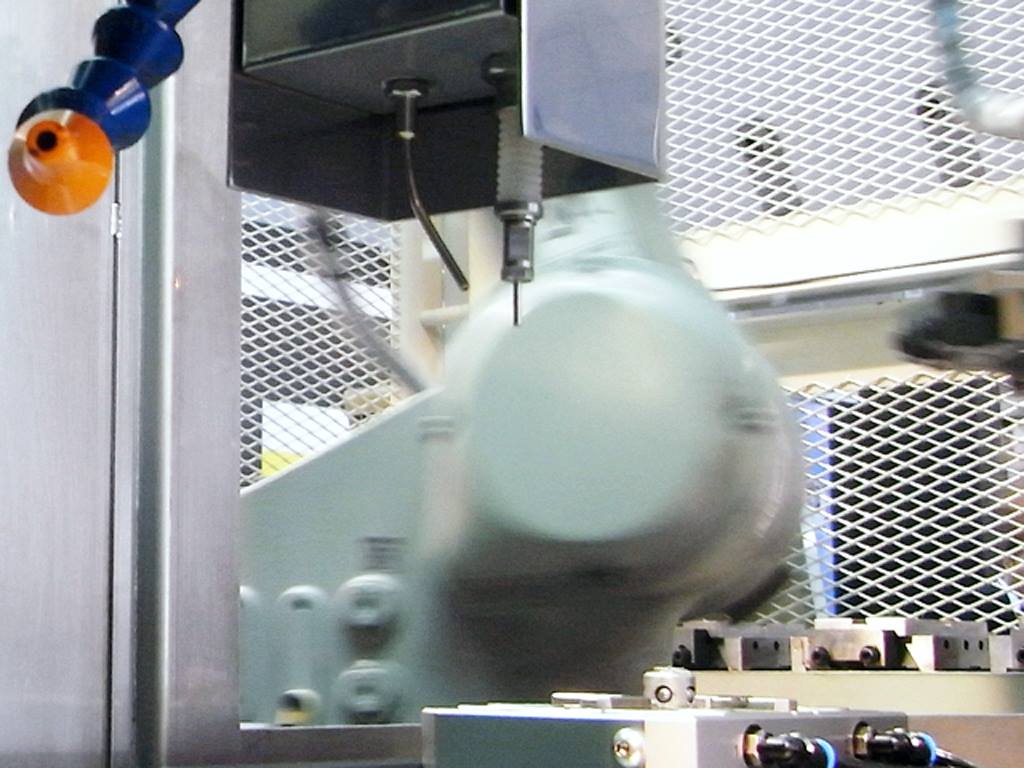

Industrial robots can be around everywhere in Japanese "Monozukuri (manufacturing)" scenes.

These industrial robots are essential for automating automobile and semiconductor manufacturing lines, and Metrol's "Made in Japan" technology also plays a vital role behind those industrial robots.

Industrial robots are equipped with many digital sensors, such as, optical sensors, touch sensors, vision sensors, angle sensors, and speed sensors… which could play as their eyes and hands.

Among all sensors,

"positioning" is the most important applications can be done with sensors in determining the original position of the robot.

For example, welding Robots will start welding all together when car body is carried out in the conveyer, yet even programmed welding robots cannot deliver precise performance if their original home position is not accurate.

Even with the latest digital technology, it is still not the easiest thing to get the original position precisely.

And this is where Metrol's positioning switch will come to rescue!

Original position for the robots to start welding can be easily controlled by using "positioning switch" with 0.5 micron accuracy (which is just 1/2000 of 1mm).

This "positioning switch is made of the mechanical parts and you will find no digital technology such as electronics.

With a combination of Japanese sophisticated analog techniques - "precision machining" and " precision assembling"-, high-accuracy positioning becomes possible.

Zero seek for the drills of CNC machine tools.

Our switch can be used to detect the wear of a drill at an accuracy of 0.5 μm even under a harsh environment.