Features

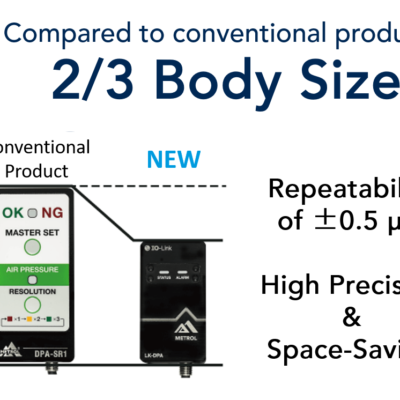

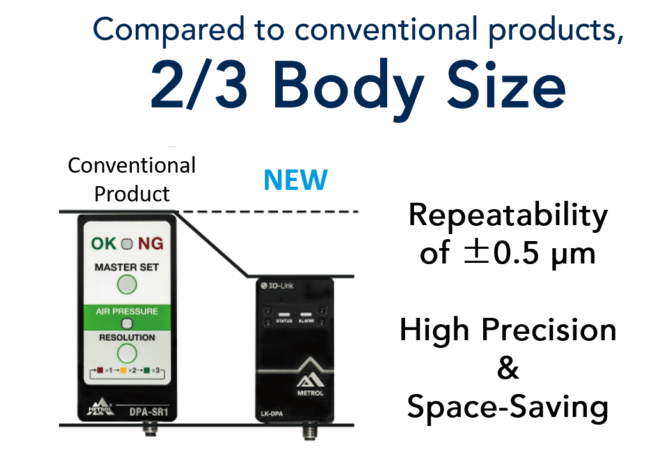

Space-saving, compact sensor

The size of the sensor has been reduced to two-thirds that of the previous product, making it easy to install in any location.

Set up to 8 thresholds

Repetition accuracy of ±0.5μm prevents any false readings

Gaps of “20 μm or less”, which cannot be detected by conventional gap sensors, are accurately detected with a repeatability of ±0.5 μm.

Reduces machining cycle time

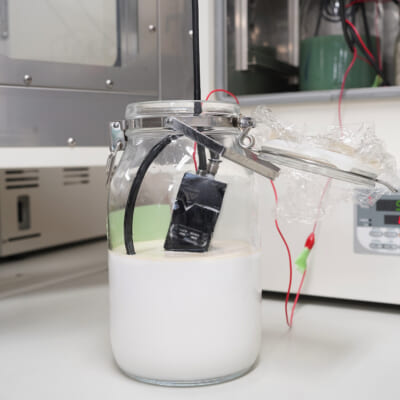

IP67 rating for protection against water, coolant, and dust, and the sensor can be installed inside the machine for shorter air piping.

Shorter pipe length improves signal response and contributes to shorter cycle time in mass production lines.

Coolant flooding tests and severe durability tests are conducted on machine tools assuming that they will be used in adverse environments.

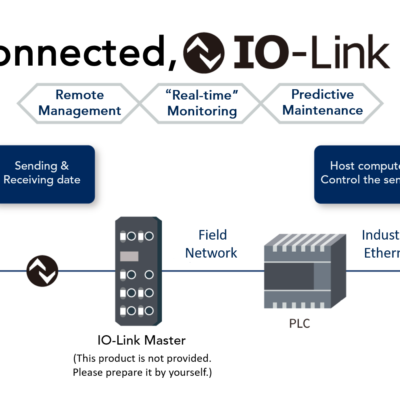

What IO-link's Air Gap Sensors Can Do For You

Remote management

The operator can set sensor thresholds from a remote location via PLC.

The supply pressure of the sensor and the amount of gap on the secondary side (nozzle side) are quantified, enabling data management through periodic output.

Continuous “Real-time” monitoring and predictive maintenance

In the event of an error such as a clogged orifice or nozzle, real-time monitoring of operating conditions enables immediate identification of the location of the error and quickest possible equipment recovery. This enables investigation and predictive prevention of factors based on internal data, and is effective in improving the efficiency of production.

In addition, when replacing or repairing sensors, information necessary for maintenance, such as product model name, year of manufacture, and other important information, is centrally managed.

![Air Gap Sensor [LK-DPA Series]](https://metrol-sensor.com/wp-content/uploads/2021/02/img_products_air_gap_sensor_lk-dpa.png)