Features

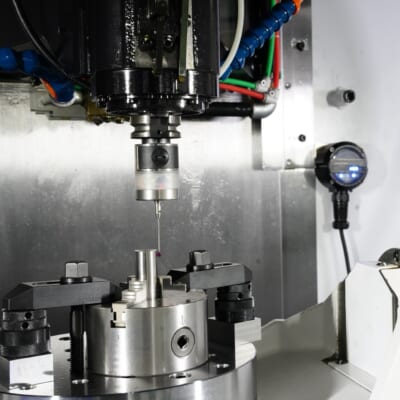

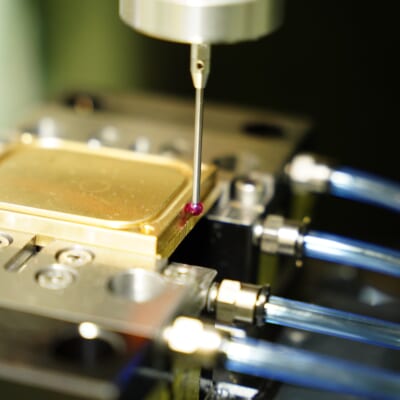

1μm repeatability (2σ), durability of 3 million cycles

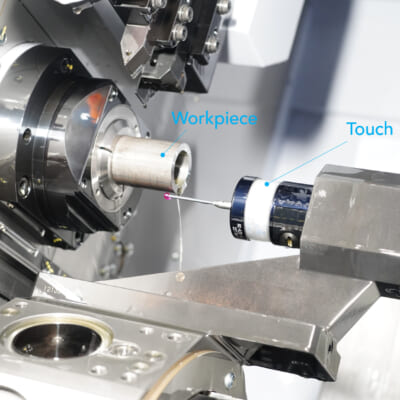

Operates at the moment the touch-probe contacts the workpiece, enabling highly precise position detection.

Noise-resistant wireless communication 2.4GHz

Our unique search technology immediately detects noise and other congestion information and changes the frequency band to be used, overcoming the effects of radio interference and ensuring stable communications.

Highly reliable wireless communication system allows signals to be sent and received from multiple directions without being affected by obstructions.

(Although “infrared communication” is considered effective for communication between straight lines, communication is blocked when obstructions are present, and stable communication is not possible.)

Resistant to vibration due to pre-travel (PT)*

(*Pre-travel: the amount of movement from the time the touch-probe contacts the work to the time the output switches)

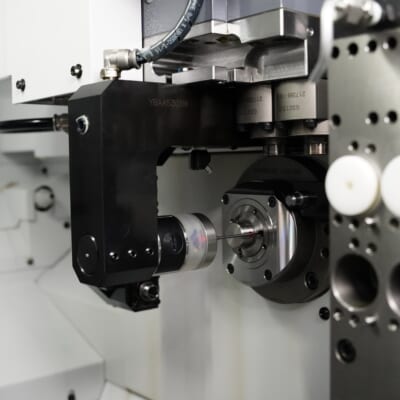

Improved receiver visibility

The receiver can be installed outside the equipment so battery level and communication status can be monitored. Compared to mounting inside the machine, cleaning and maintenance due to coolant and chip spattering is not required.

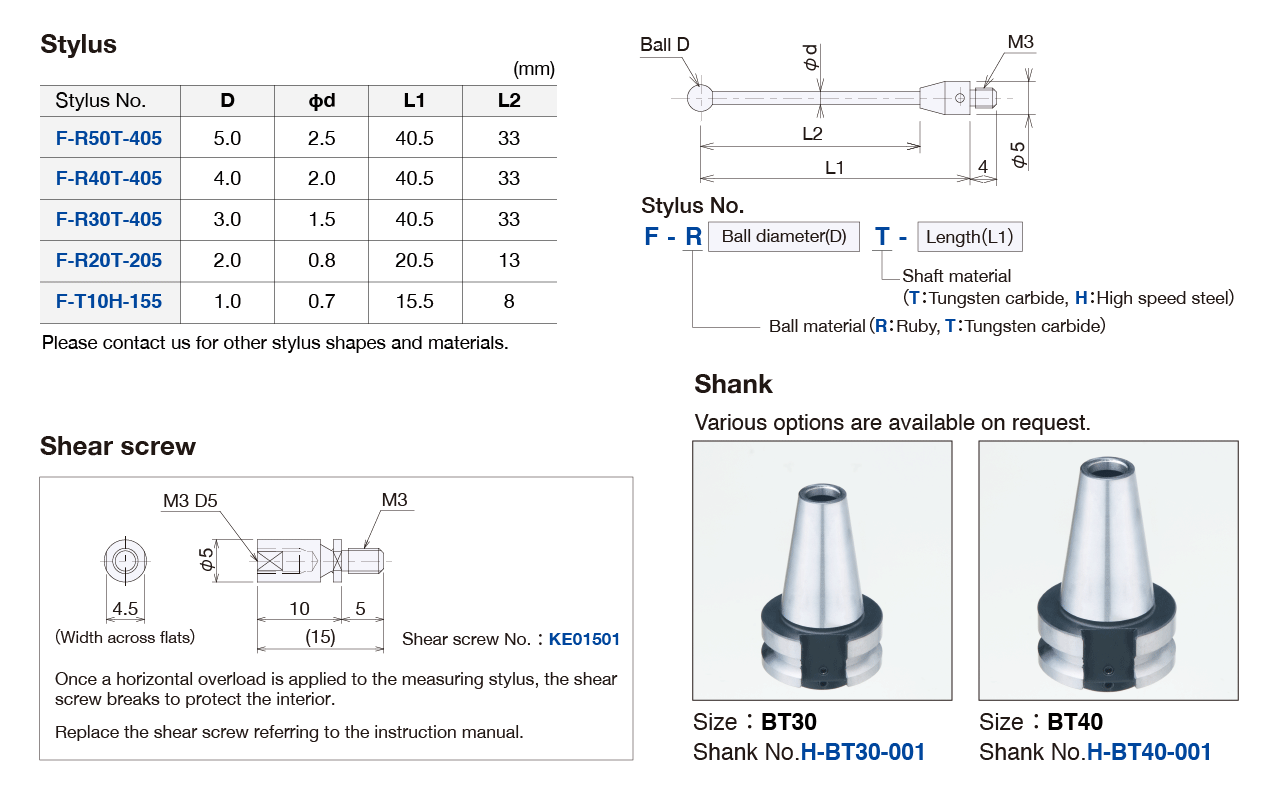

Wide variety of optional items

Stylus, mounting method, cord length, and other options can be selected.

Expedited after-sales follow-up service

We can provide immediate support for inquiries on sensors and adjusting delivery dates of parts.

Most of the 3D touch probes made by other companies have imported parts, thus repairs and parts replacement are expensive. Lead-times for responding to inquiries also generally tend to be longer.

Since METROL completes all manufacturing processes in Japan, we can quickly provide follow-up services, including investigation reports, in the event of any problems.

Waterproof and oilproof construction with IP68 rating: Resistant to Water and Liquids

RC-K3X Series are designed for use in adverse environments and has passed high-pressure coolant durability tests inside machine.

High repeatability even when used in machine tools with splashing coolant and chips.

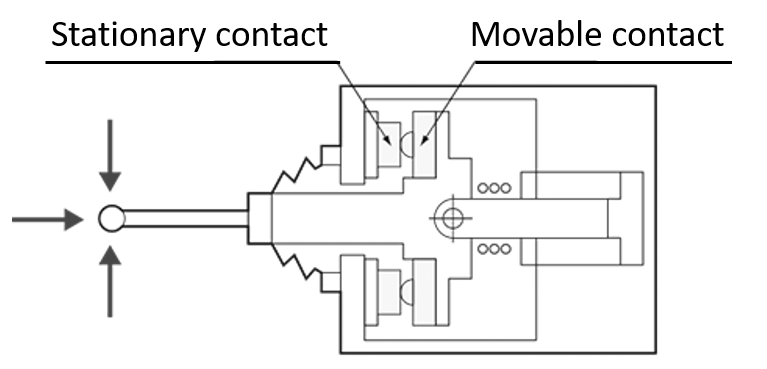

Principle Structure

By placing the touch-probe on the stylus tip against the workpiece or table, a high-precision ON/OFF signal is output, which can be input to NC/PC equipment.

The moving part swings with the three points of contact as fulcrums. Since the contacts play the role of fulcrums, a momentary ON/OFF signal is output when one of the fulcrums is detached.

*The contact force varies depending on the direction of detection. If the contact force varies depending on the detection direction, a perfect circle will not be formed when measuring a perfect circle shape (roving phenomenon), and thus it is necessary to take this specific quality into account.

![Wireless High-Precision Touch Probe[RC-K3X Series]](https://metrol-sensor.com/wp-content/uploads/2021/02/RC-K3X-image.png)