Why METROL Wins Customers

Reason 1:

Protection rating IP67 against water, coolant, dust, and also supports high-speed application.

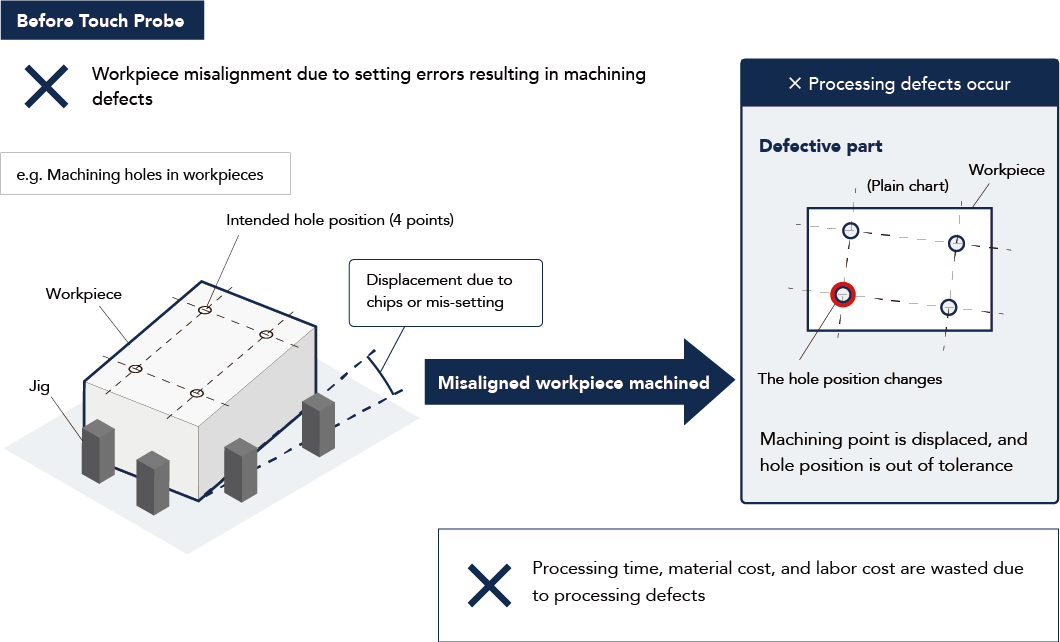

Touch probes must be able to perform stable detection even in adverse environments exposed to dust, chips, and coolant.

METROL touch probes sensors are IP67 rated for high durability and applicable on fast moving machine tools, thus contributing to shorter cycle times.

METROL is also an active user of touch probes in our own factory. We have conducted severe coolant and durability tests on actual machines and have implemented the necessary functions for touch probes from the user's perspective through a series of improvements.

Reason 2:

A wide-ranging product lineup to choose from

Our touch probe sensors can be used in a wide variety of customer applications.

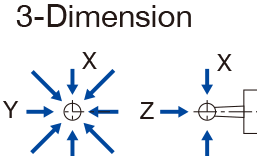

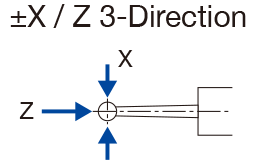

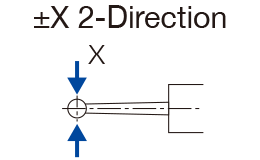

Wired or wireless type, as well as 1-to-3-dimensional direction of detection can be selected, and various customizations such as flange for mounting, LED, cable connector, in addition to other options, are all available.

All stylus (measuring probes) for touch probe sensors are designed and made in our own factory, and we can design them in any shape and material to suit your purpose and needs.

Reason 3:

Low-cost, expedited engineering services achieved by Made-in-JAPAN quality

“I want to use touch probe sensors, but it is too pricey”

“We use touch probes from another company, but they take time to respond to repairs, inquiries, etc.”

In recent years, the need for touch probes has increased dramatically due to factory automation, but touch probes made by other brands are still expensive in terms of both price and maintenance costs.

METROL touch probe sensors are manufactured extensively in Japan while maintaining low prices. Even in the unlikely event of a technical problem, the most advanced inspection equipment will be used to investigate and identify the cause of the problem. Our engineers will provide expedited service that can only be provided by METROL.

Reason 4:

Highly trusted communication performance

With the spread of 5-axis machines and robots, the need for wireless touch probes is rapidly increasing.

Our wireless touch probe series consists of a 2.4 GHz band and highly reliable software to ensure stable communication. The battery, which has been a bottleneck in the past, can now be used continuously for long periods of time, contributing to a reduction in the maintenance burden.