[CNC Lathe Users MUST SEE! ] How to Reduce L-dimension defects in Machined Parts to Zero?

Table of Contents

CNC Lathe Users,

Do you have any of these problems?

- When chucked, chips cause the bar material to float, resulting in poor processing…

- Once a processing defect occurs, a large number of defective products are made in succession…

- After defective products are generated, it is very difficult to inspect all the products to determine whether they are good or bad…

- Measurement errors can occur depending on the inspector.

We have also received the following problems from our clients.

Customer’s Concerns: Longitudinal dimensional defects in workpieces after lathe turning.

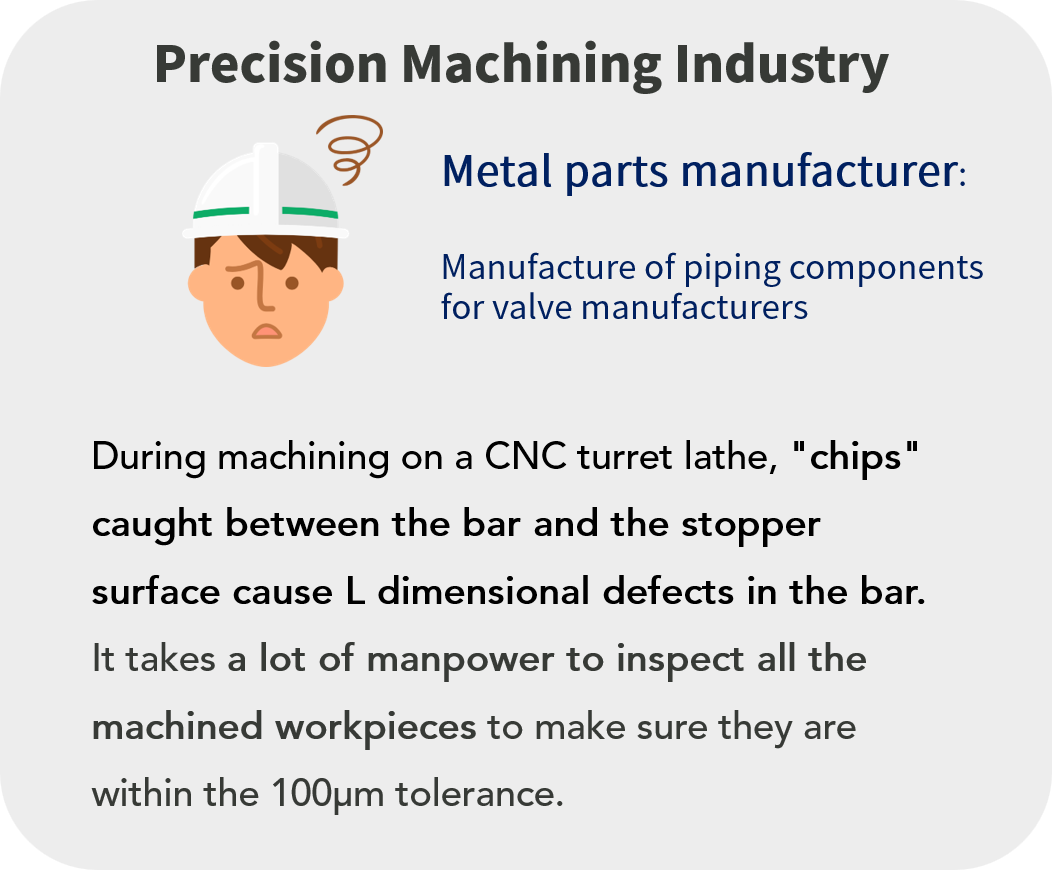

Here is a case study of a processing company that processes bar materials for valve manufacturers.

Key Point of the Issue

Longitudinal defects in workpieces occur, requiring manpower for full inspection.

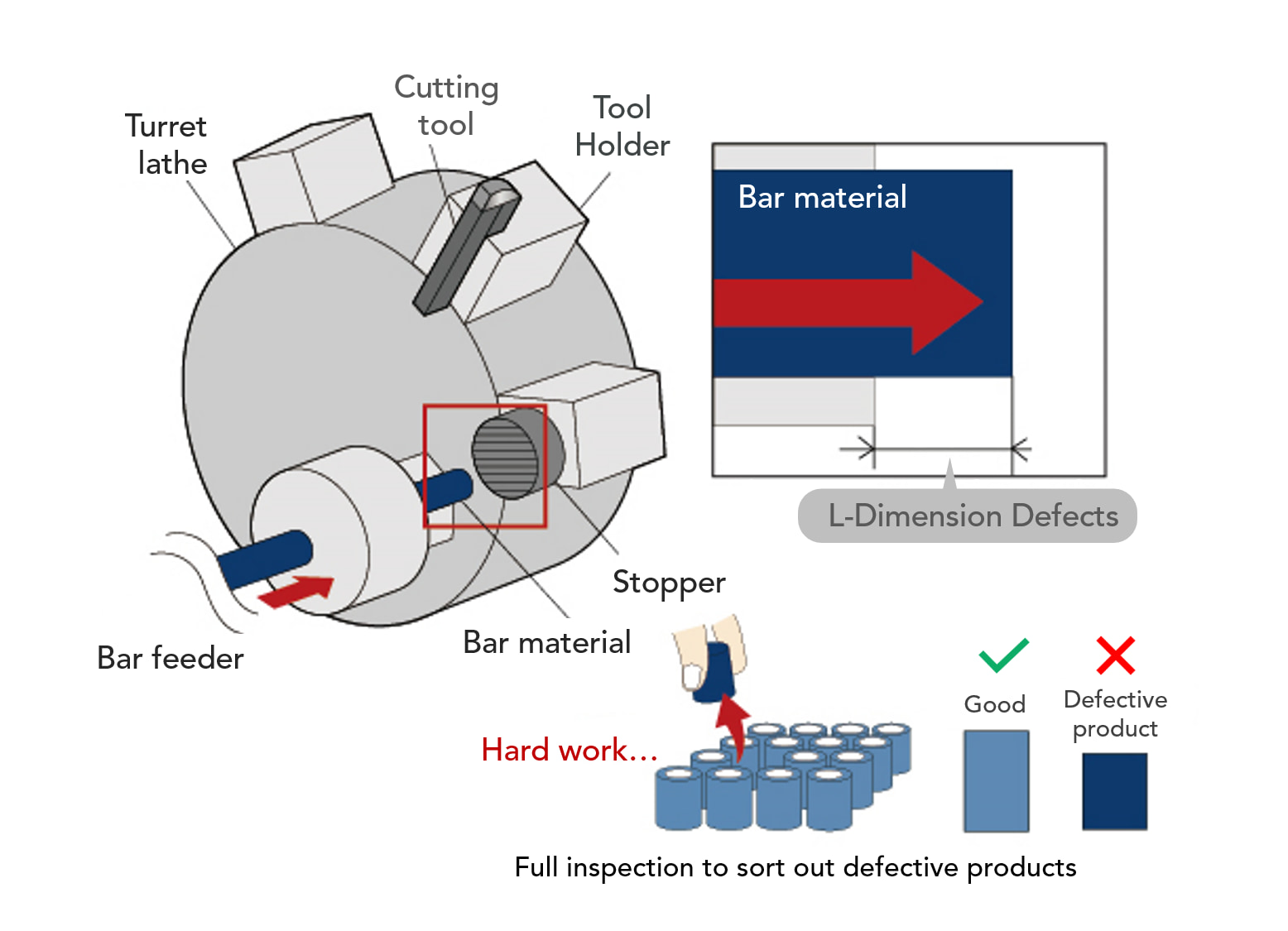

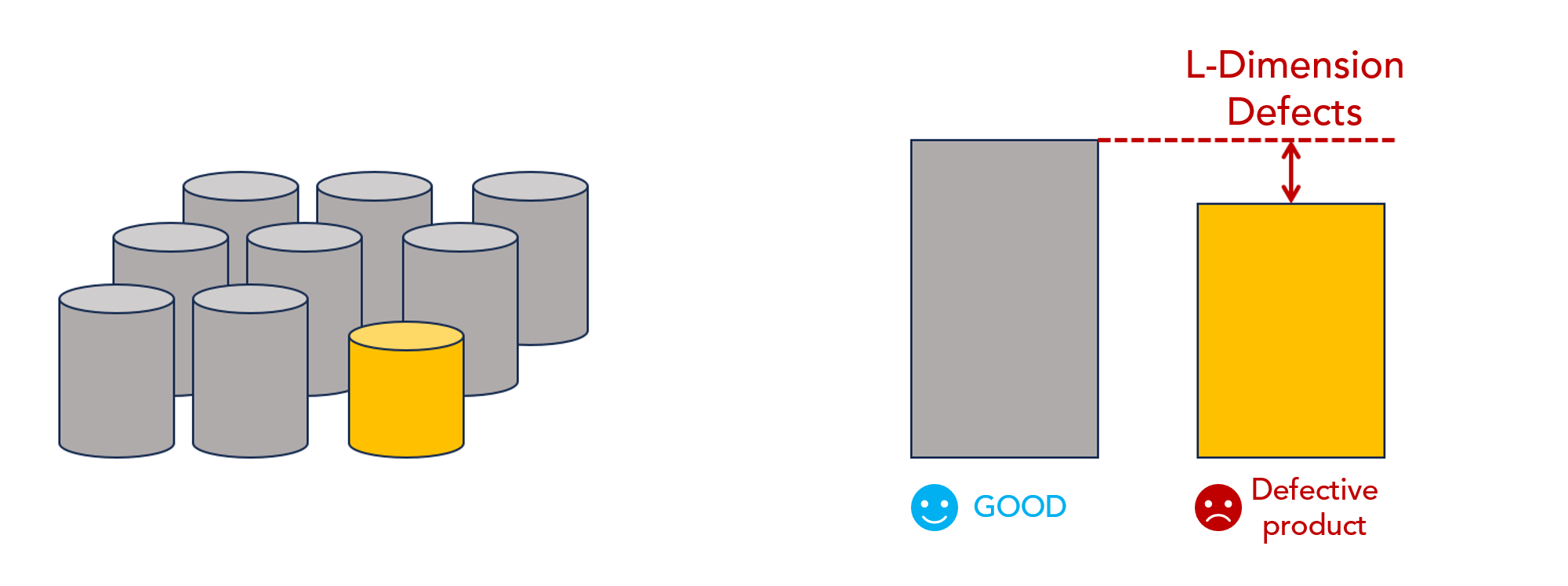

A common cause of longitudinal dimensional defects is workpiece lift due to "chip bite".

Cases of workpiece floatation causing differences in the overall length of the workpiece after machining are common among turret lathe users.

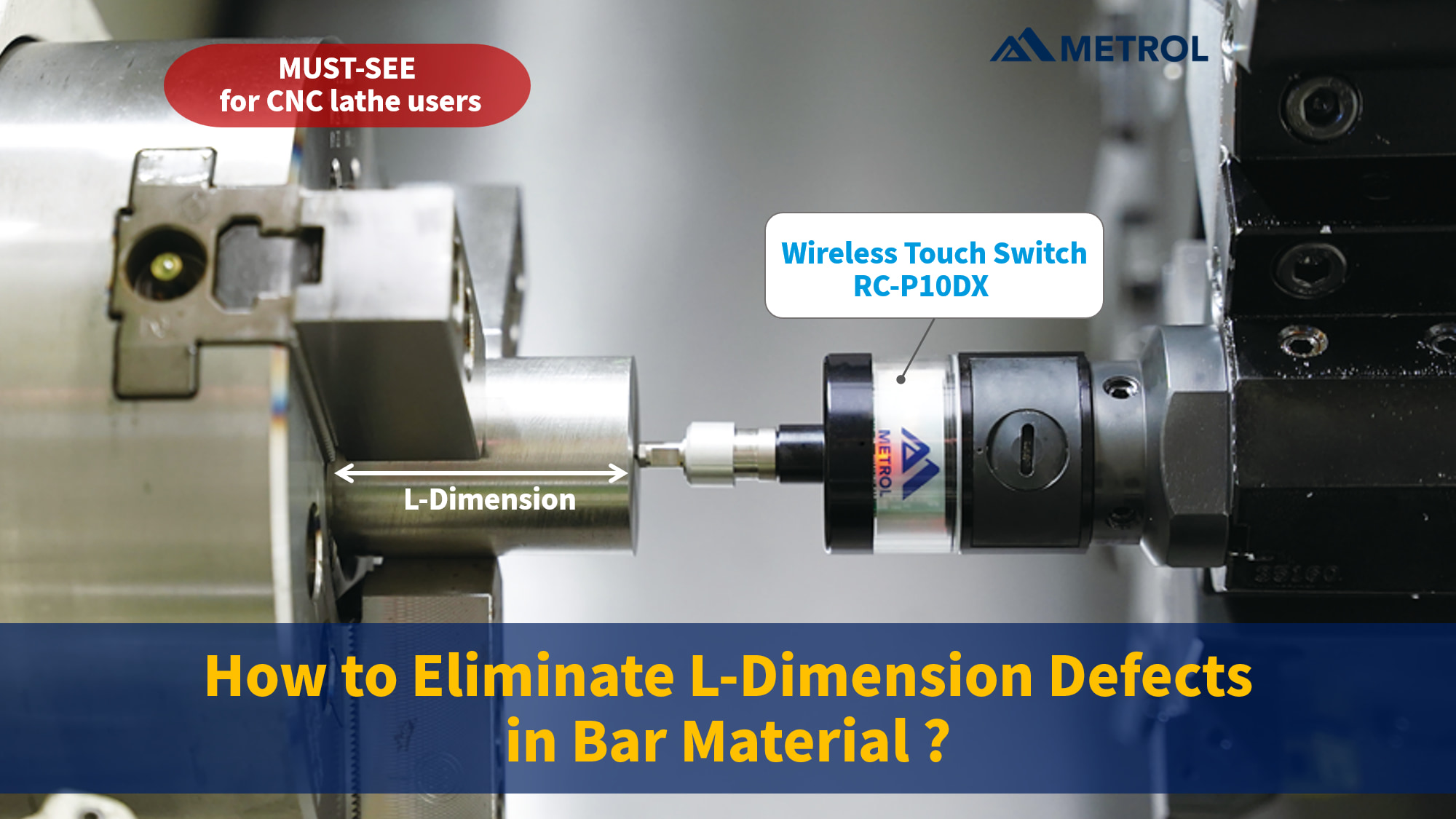

In this issue, we will explain [Position Detection Touch Switch RC-P10DX] , which solves the problem of "longitudinal dimensional defects.

What is the [Wireless Touch Switch RC-P10DX] that prevents dimensional defects in the longitudinal direction?

We introduce a wireless touch switch to prevent dimensional defects in bar material processing, as in the case study at the beginning of this article.

Product Features

Features of Wireless Touch Switch RC-P10DX

- Wireless contact-type touch switch

- High-precision detection of L-dimension of workpiece

- Because it is wireless, it can be mounted on turret-type and 5-axis machines where wiring is difficult.

- corrects thermal deformation of the spindle with 1μm repeatability

- Noise-resistant 2.4GHz wireless communication

Touch switch RC-P10DX uses a wireless communication system, eliminating the need for cables, unlike conventional touch switches.

It include:

- touch switch (main unit) that serves as a transmitter

- receiver that receives signals.

What is WIRELESS Type? Difference from ordinary touch switches.

The touch switch sends a detection signal to the control side (e.g., PLC) through a cable when the contacting part touches the workpiece and is pushed in. This entails the risk of wire breakage and wiring routing for maintenance and replacement.

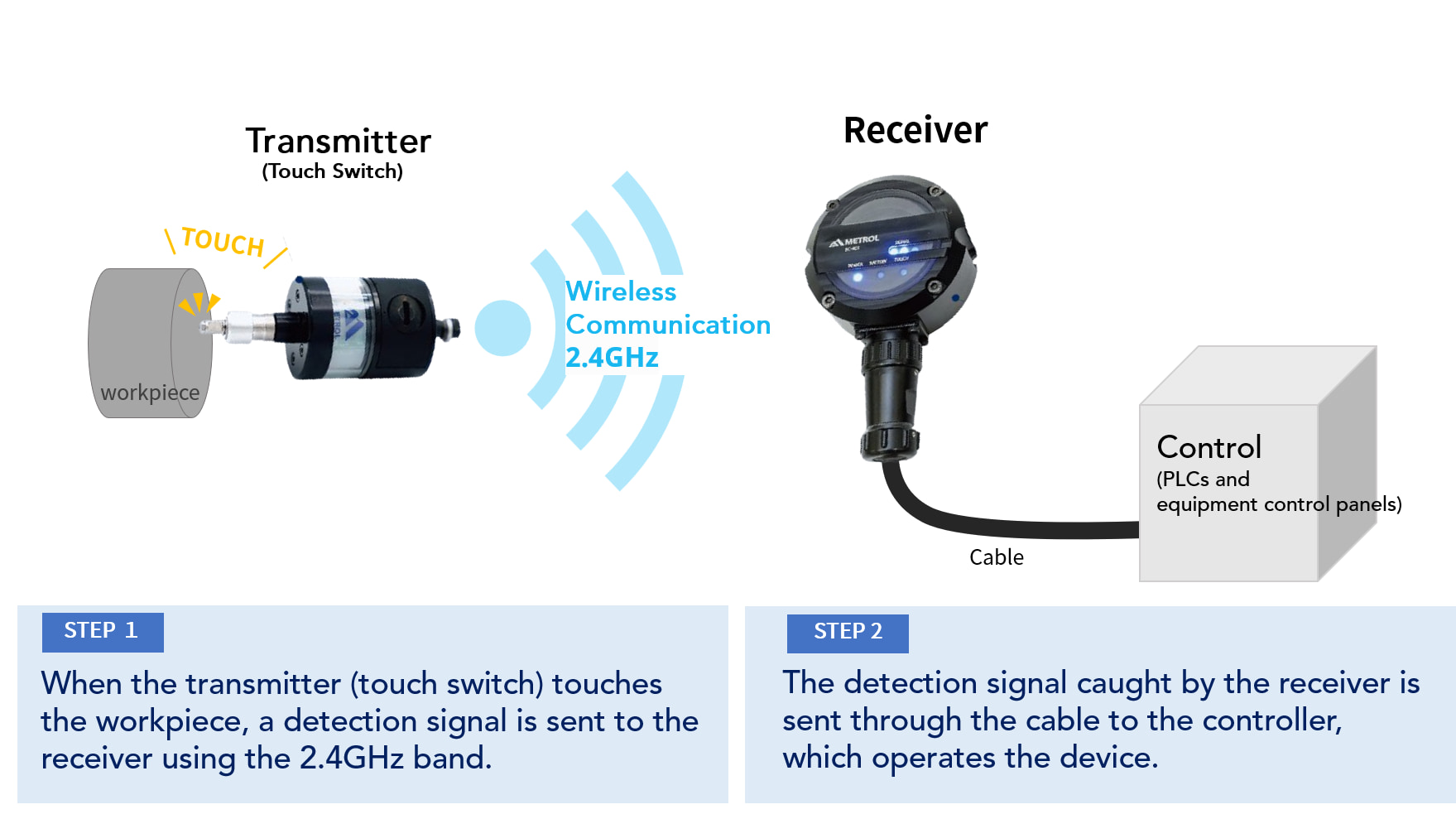

[Principle Explanation] Radio Transmitter/Receiver System Using 2.4GHz Band

The transmitter (switch) is wireless and sends signals from the built-in antenna to the receiver.

STEP1: When the touch switch contacts the workpiece, a signal is sent from the built-in antenna to the receiver. (Uses 2.4GHz band)

STEP2: Send the received signal to the control side (PLC or control panel) to which the receiver is wired to operate the device.

Two Issues Solved by the Touch Switch RC-P10DX

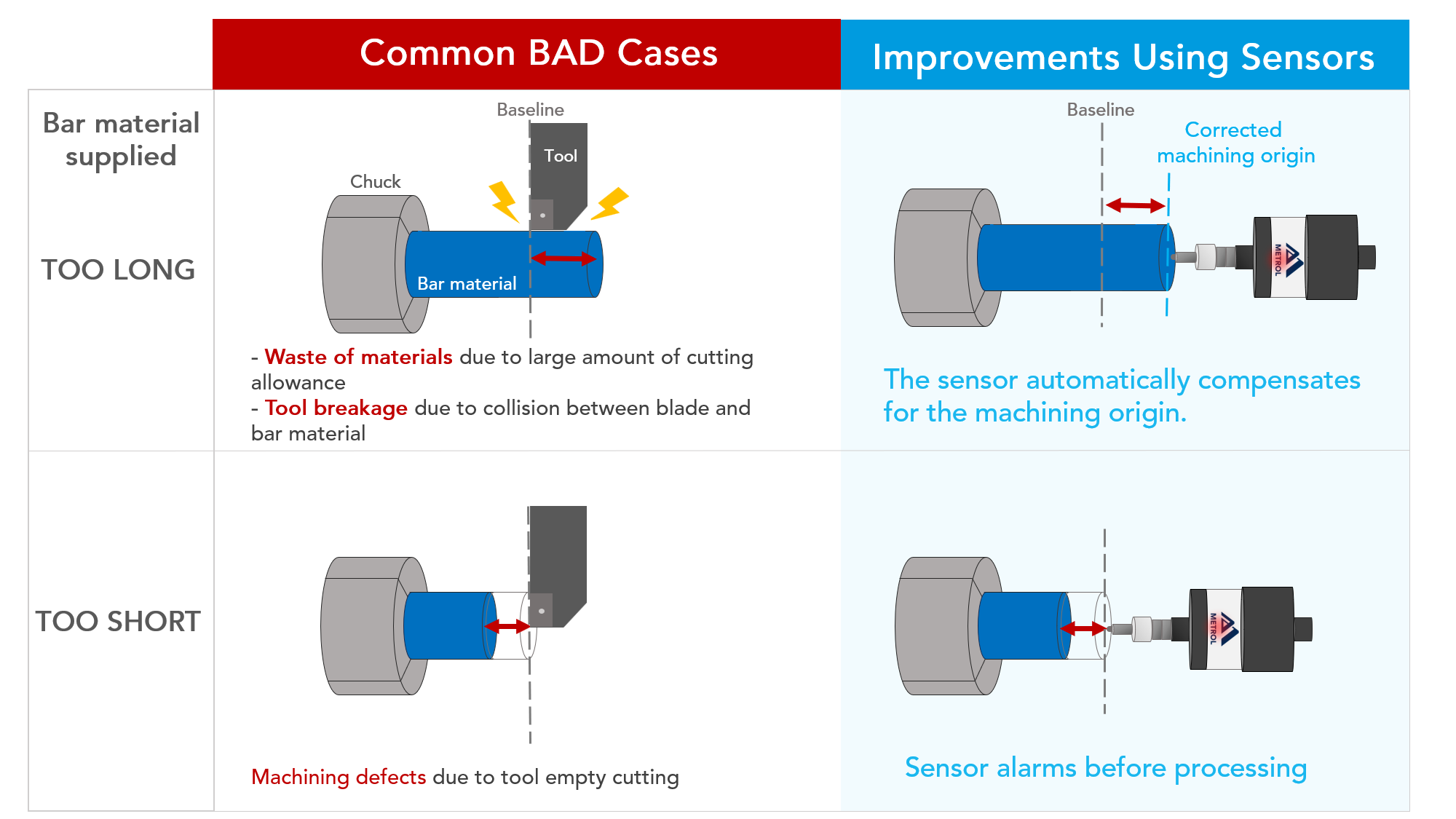

Installing wireless touch switch RC-P10DX on CNC turret lathes can prevent post-processing L-dimension defects caused by the following

1. Lifting of workpiece due to chips

2. excessive or insufficient bar material withdrawal

This contributes to the reduction of defective products and the burden of inspection processes in mass-production processing.

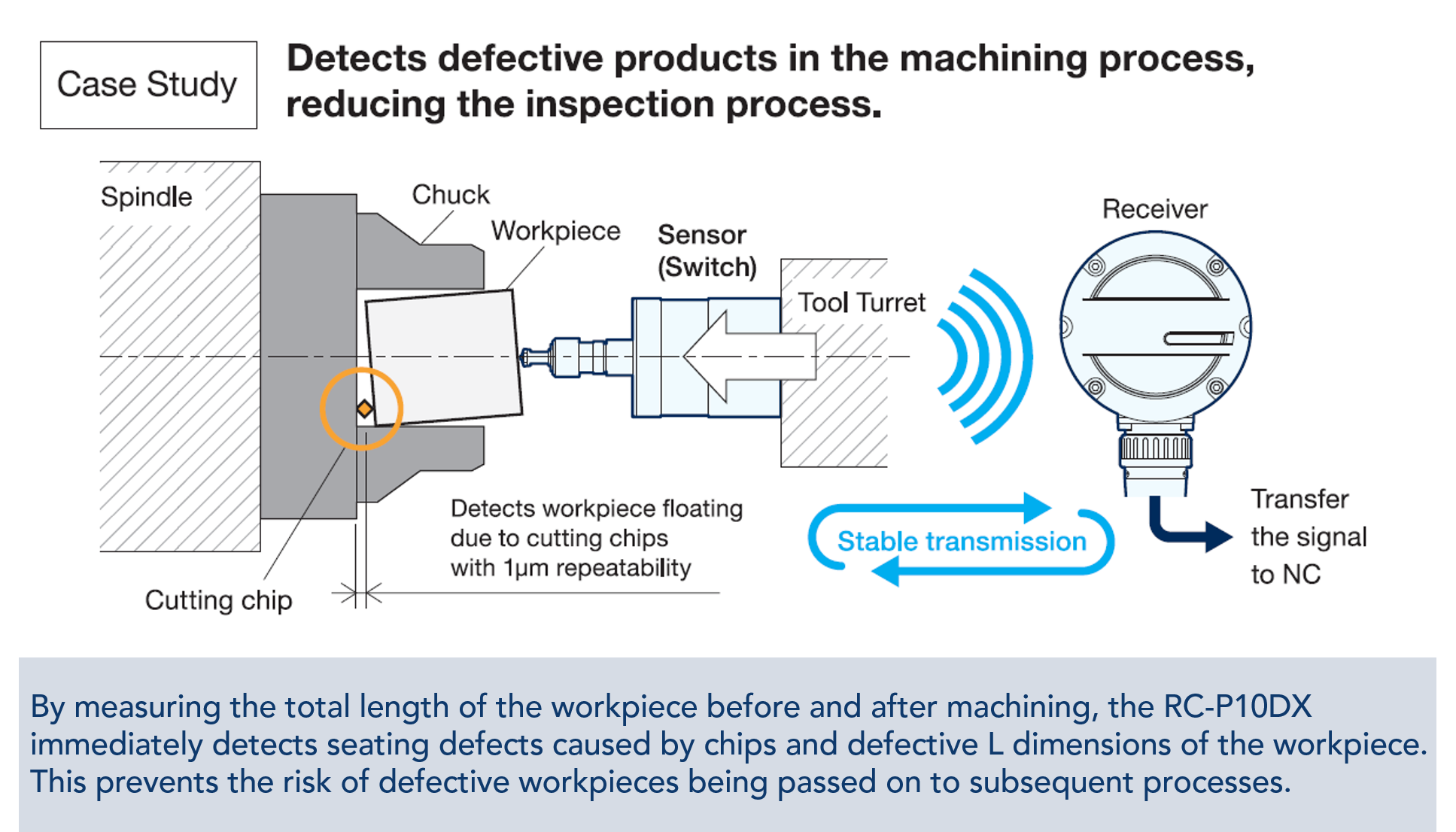

Issue 1: Detection of floating bar material

If chips are caught when chucking bar material, the workpiece will tilt, causing defects.

The use of the touch switch detects minute lifting and prevents processing defects before they occur.

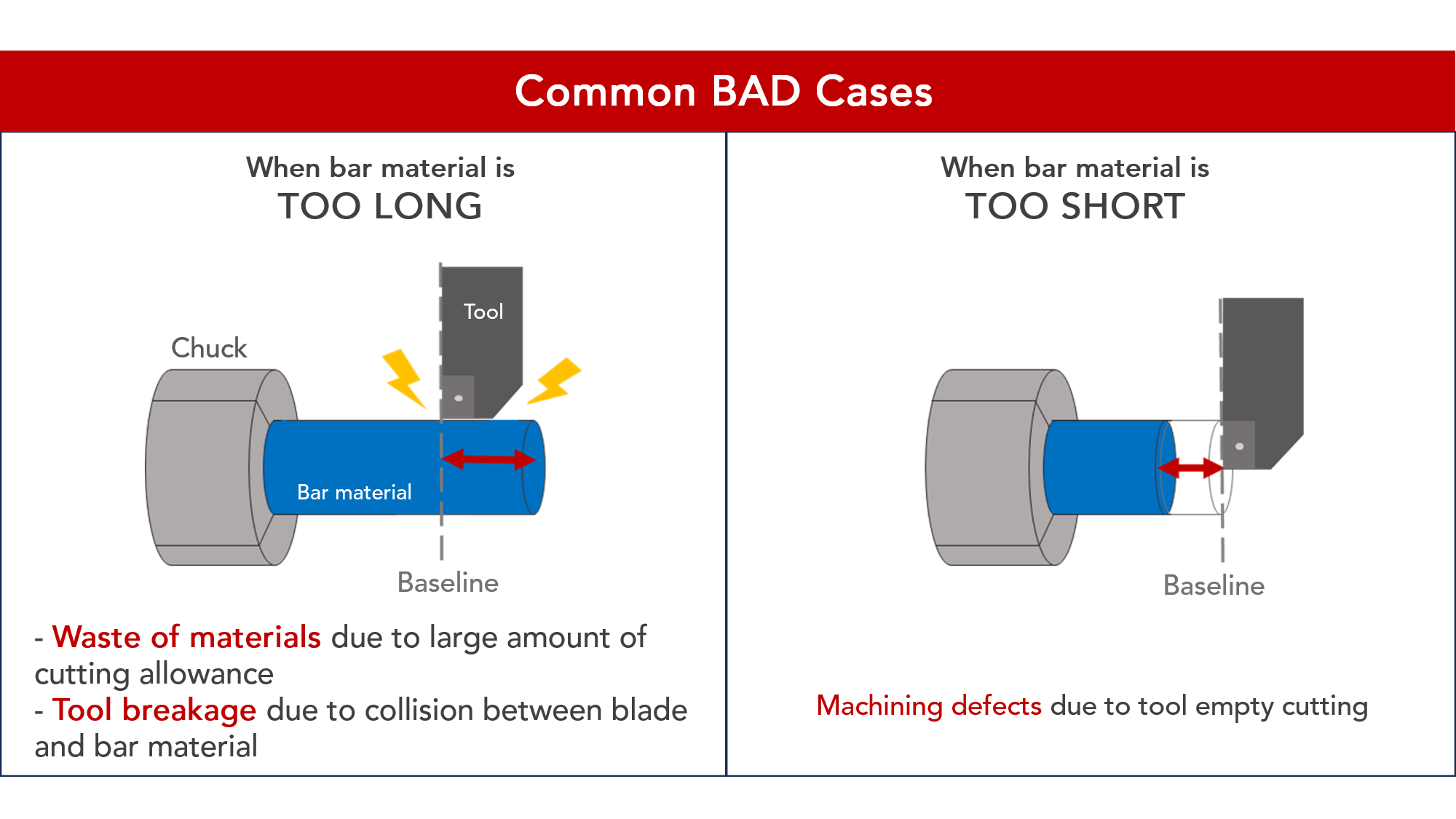

Issue 2: Detecting the amount of bar material withdrawn

In bar feeders, excessive or insufficient bar material withdrawal can cause processing defects.

Prevents machining defects by measuring the total length of the workpiece before and after machining with the touch switch RC-P10DX

Step 1:Touch the workpiece with the touch switch RC-P10DX (transmitter).

Step 2:If lifting of the workpiece due to chips is detected, an alarm is issued, the machine is stopped.

Step 3:Remove workpieces with defective L dimensions before machining

The above procedures prevent the risk of processing defects and the outflow of defective products to subsequent processes.

It also leads to a reduction in man-hours required for full inspections.

[Demo Video] CNC Turret Lathe - L Dimension Defect Detection of Bar Material [Touch Switch RC-P10DX]

[Video] Case Study: How to Use the Touch Switch RC-P10DX

Watch the video to see the process by which the RC-P10DX touch switch measures the workpiece before and after machining on a CNC turret lathe.

Three Advantages of Introducing the RC-P10DX Touch Switch in CNC Turret Lathes

1. Cost Reduction (processing time and materials)

By installing the touch switch RC-P10DX , machining time on CNC turret lathes can be shortened and material waste can be reduced. This will result in cost reductions.

2. Automation and Efficiency of Full Inspections

Automating and streamlining the inspection process of processed products reduces the time and labor required to inspect all products and reduces the burden on inspectors. It also helps to eliminate manpower shortages.

3. Quality improvement and standardization of inspection work

In-machine measurement of CNC lathes using touch switches enables early detection of defects in machined parts.

In particular, L-dimension defects can be detected more quickly, improving the yield rate of continuous machining.

Standardization of inspection work improves quality.

The "RC-P10DX Series" introduced here is widely used to eliminate machining defects on turret lathes, including L-dimension defect identification of bar materials on turret lathes and thermal displacement compensation of machines.

If you are having trouble with L-dimension defects in workpieces on turret lathes, please contact us!

Please feel free to contact us.

Our engineers will respond to any questions regarding product usage methods or requests to customize products.

We can provide our best support if details about application, usage environment and what kind of workpieces will be detected can be provided.

Use our contact form below to contact us.