Measuring height of the nozzle of the dispenser at a low cost

Electronic device industry

A device manufacturer that produces desktop soldering robot essential for small and multiple types of model production.

A representative of the development of dispenser for smartphones inquired us about "height measurement" of the nozzle in applying adhesive.

Table of Contents

Client’s Issues

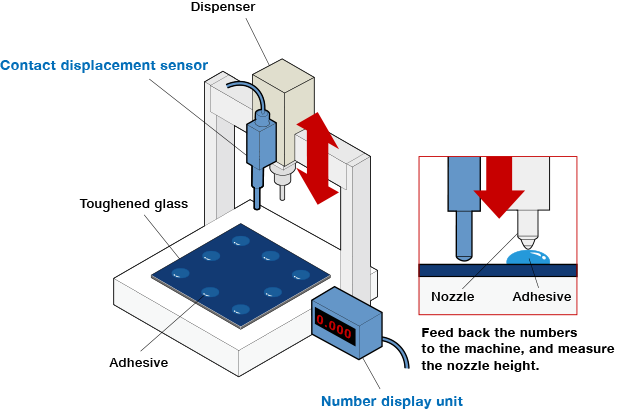

The "contact-type displacement sensor" has been used for measuring the height of the nozzle of dispenser with adhesive, however, the device was expensive and this was a financial burden.

The nozzle height measured before applying adhesive is provided for the feedback on the values to the machine, however, the 1 μm or better high accuracy is required also for controlling the amount of application precisely.

With the adhesion application of tempered glass for smartphones expanding, the client's company found a sensor that can measure the nozzle height at low cost and contacted us.

The main focus of the issues

Contact displacement sensor is expensive.

Repeatability of 1μm or more is needed.

Metrol’s suggestions

For a measurement in automated lines for detecting constant positions, the number display (displacement measurement) is often unnecessary, and "Contact-type displacement sensor" gives the dispenser overperformances for such application in many cases.

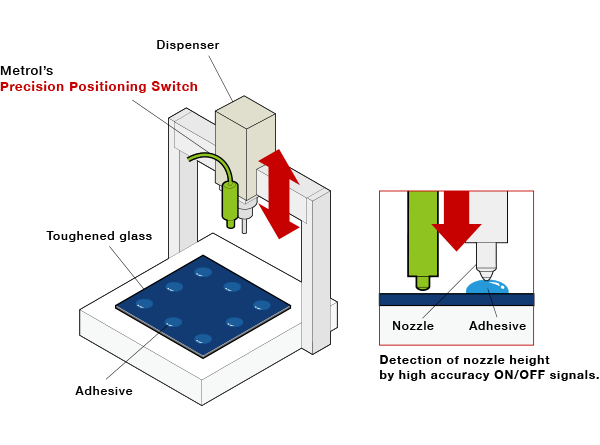

Metrol's "precision positioning switch" can detect the nozzle height with high accuracy ON/OFF signals.

Though the accuracy of the switch is the same as that of contact-type displacement sensor, the switch can reduce the cost to about 1/10.

Furthermore, the contact tip material can be changed to resin to reduce the contact force, so there is no risk of scratching the tempered glass for smartphones.

Improvements

Reduced the cost to 1/10 by eliminating the number display.

Realization of repeatability of 1μm.

Comment from Metrol representative

Is the number display really necessary for positioning in automated lines and in-lines?

As stated already, in many cases, a significant cost reduction has been achieved by replacing expensive "contact-type displacement sensor" with Metrol's "precision positioning switch".

If you are in trouble with the higher cost of "contact-type displacement sensor", do not hesitate to contact us.

For further information about the products used in this application

Ultra-small Precision Positioning Switch [PT]

Repetitive accuracy of 1μm!

A review the number display in the automated lines can considerably reduce the cost to 1/10.