Detection of tool wear by CNC machining center has realized the improvement of the machining accuracy

Precision machining industry

A precision machine machining manufacturer that produces precision parts for major aerospace manufacturers.

A representative of the cutting department consulted us on "detection of wear" of tools in cutting by machining center.

Table of Contents

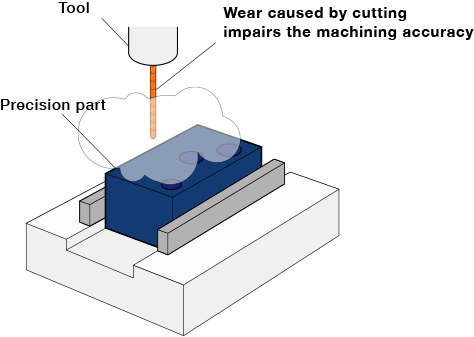

Client’s Issues

The client faced with a problem that the machining accuracy is impaired by tool wear in cutting precision parts by CNC machining center.

Because of precision parts used for space development, 1 μm machining accuracy is required. However, the tool preset by an experienced engineer is required to correct tool wear, as a result, the operation rate is reduced by trial scraping, measurement, and NC input.

Furthermore, the unmanned operations for 24 hours a day has had the tools damaged and caused defective products.

The main focus of the issues

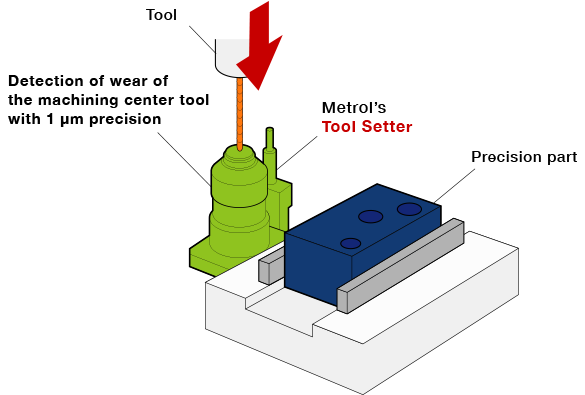

Detection of wear of the machining center tool with 1 μm precision.

A tool preset by experienced engineers reduces the operation rate.

No defective product caused by tool damages.

Metrol’s suggestions

The tool length constantly changes under harsh working conditions where coolant and cutting chips splatter inside the CNC machine tools such as cutting wear, temperature difference between daytime and nighttime, and the thermal displacement of the machine.

Metrol's "tool setter" detects and corrects the tool wear with 1 μm precision by feeding back the values of the tool length to NC.

Because the conventional expertise such as trial-scraping, measurement, and NC input are no longer needed, the operation rate is considerably increased.

Generation of defective products can be prevented by automatic detections of tool damages and automatic stop of machines during unmanned operations.

Improvements

Realize detection of wear of the machining center tool with 1 μm precision.

A tool preset by experienced engineers is no longer required, and the operation rate is increased.

Prevent defective products by detecting accidental tool breakage in machining process.

Comment from Metrol representative

Our "Tool setters" developed in 1983 received a high evaluation for the high accuracy and durability and have been shipped not only to major Japanese machine tool makers, but also to 70 machine tool makers in 17 countries.

(Awarded "Global Niche Top Companies Selection 100" by Ministry of Economy in 2014)

In some cases, we can also introduce specialized retrofit service providers. Please feel free to contact us.

For further information about the products used in this application

Tool Setters for CNC Machining Centers

Wear of the machining center tool is detected with 1 μm precision!