The thermal displacement of the grinding stone has been corrected under harsh working conditions on the grinder where coolant splatters.

Machine tool industry

A machine tool manufacturer that produces CNC downsized machines for machining smartphones.

A representative of the grinder design department inquired us about "thermal displacement" of grinding stones in processing glass.

Table of Contents

Client’s Issues

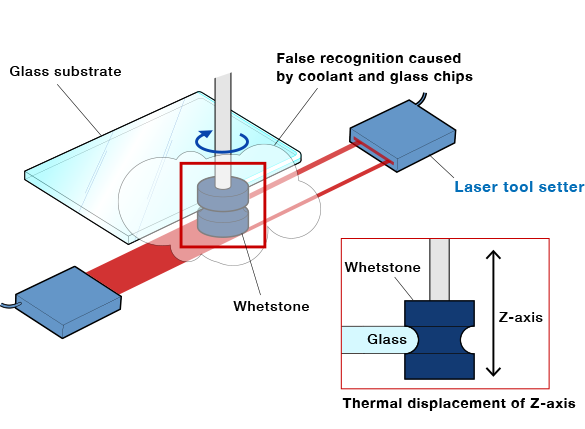

In grinding glass for smartphone precisely, the Z-axis of the grinding stone varies due to thermal displacement caused by self heating of the grinder, the machined surface R cannot be grinded according the measurements.

Although thermal displacement correction by high-priced, laser-type "tool setter" was also considered, under harsh working conditions in the grinder where coolant and glass chips splatter, frequent false detections prevent stable correction.

As user facilities increase, the cost reduction is required for the machines, and the improvement for the machining accuracy, so the client found our "tool setter" and contacted us.

The main focus of the issues

The thermal displacement for the grinding stone of the grinding machine should be corrected.

False detections of tool setter due to coolant and glass chips.

Laser type is expensive

Metrol’s suggestions

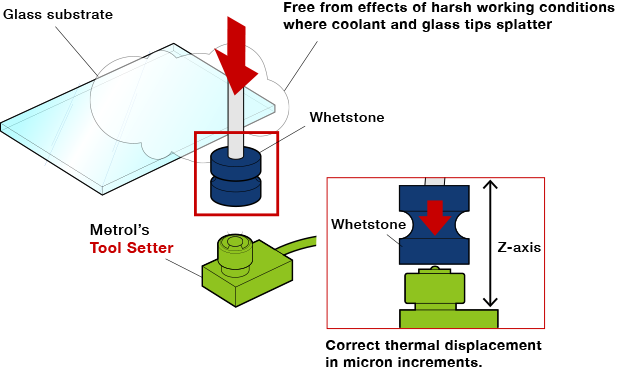

Because the laser type "tool setter" detects tools without contact, it is subject to external conditions, under harsh working conditions where coolant and cutting chips are splatter inside machine tools, it cannot demonstrate the performance fully.

Because Metrol's "tool setter" directly contacts and detects tools with the IP67 protection structure, it is more resistant to harsh working conditions relative to the competitors' laser-type setters and capable of correcting wear and thermal displacement of tools with the 1μm repeatability.

For contact-type, the grinding stone must stop rotating for detections, however, the price can be reduced to 1/10 or less though it has the same precision level as a laser type.

Improvements

Correcting thermal displacement of the grinding wheel in micron increments.

The contact-type is free from false detections caused by coolant and glass chips.

The cost of laser-type has been reduced to 1/10.

Comment from Metrol representative

Our "Tool setters" developed in 1983 received a high evaluation for the high accuracy and durability and have been shipped not only to major Japanese machine tool makers, but also to 70 machine tool makers in 17 countries.

(Awarded "Global Niche Top Companies Selection 100" by Ministry of Economy in 2014)

If you have any trouble with wear and thermal displacement of machine tools or false detections of laser-type tool setter, do not hesitate to contact Metrol.

For further information about the products used in this application

Tool Setters for CNC Machining Centers

The thermal displacement of tools has been corrected under harsh working conditions inside machine tools!

Improve machine accuracy of CNC machine tools.