Stably detected a gap caused by foreign materials put between the press molds without contact

Mold industry

An automotive parts manufacturer that produces a part of suspension system for major automakers.

A representative of the presswork department inquired us about "detection of gaps" caused by foreign materials put between the molds in applying hydraulic press.

Table of Contents

Client’s Issues

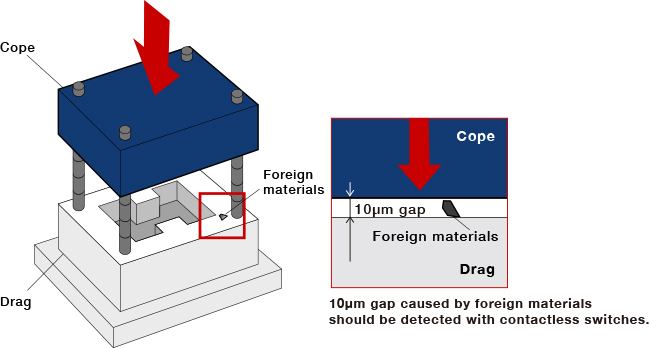

A presswork has been applied to a part of automotive suspension system using an electric-servo-type hydraulic press machine, however, then foreign materials are put between the cope and drag and gaps are generated.

Even a 10μm gap between the cope and drag results in defective products.

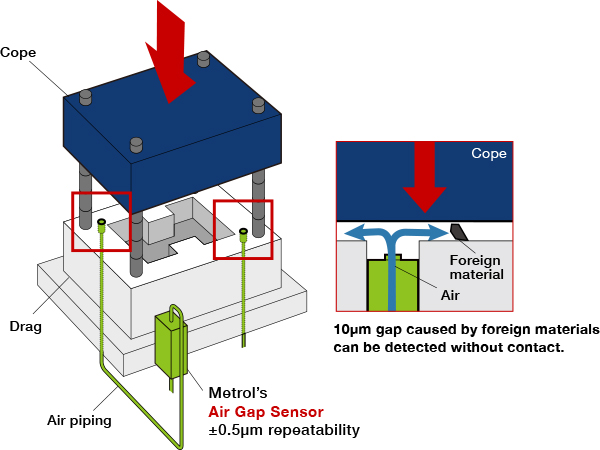

A "without contact" detection method has been needed because the mold and its surrounding are hot, however, the accuracy of conventional "air sensor" is low (about ±10 μm), and any gap caused by 10 μm or less foreign materials cannot be detected.

A visit of our booth in the "Intermold Exhibition" for mold technologies encouraged the client to know our sensors and to contact us.

The main focus of the issues

10μm gap caused by foreign materials should be detected with contactless switches.

Metrol’s suggestions

Because the pneumatic sensor such as "air sensor" and "gap sensor" use pressure-sensitive elements called "pressure transduction elements" on its sensing detection part, it is subject to variation of signal points by temperature drift and not suited for confirmations of precise adhesion.

Metrol's "Air Gap Sensor" demonstrates ±0.5μm repeatability which cannot be achieved by conventional "air sensors".

Because of the realization of stable detection of 10 μm gaps caused by foreign materials and its high repeatability, on-site frequent conformities with the master are not required.

Improvements

10μm gap caused by foreign materials can be detected without contact.

Comment from Metrol representative

Like the cases introduced here, our products have been continuously adopted in the mold industry that requires high accuracy in applications such as "starting point" for a lens mold and "detection of gap" for a cast mold.

Also, using not only the non-contact-type "Air Gap Sensor" but also contact-type "heat-resistant switch" realizes downsizing the molds in many cases.

If you have any trouble with an adhesion confirmation of mold, please feel free to contact us.

For further information about the products used in this application

Air Gap Sensor [Short range detection type]

10μm gap caused by foreign materials can be detected without contact.

Realize "Precision seating confirmation" of the jig and workpiece.