Stably detected an uplift of the jig and workpiece of the CNC machine tool without contact.

Automobile industry

An automotive parts manufacturer that produces die casting engine parts for major automakers.

A representative of the machining department consulted us on "confirmation of adhesion" of the engine parts in cutting by CNC machining center.

Table of Contents

Client’s Issues

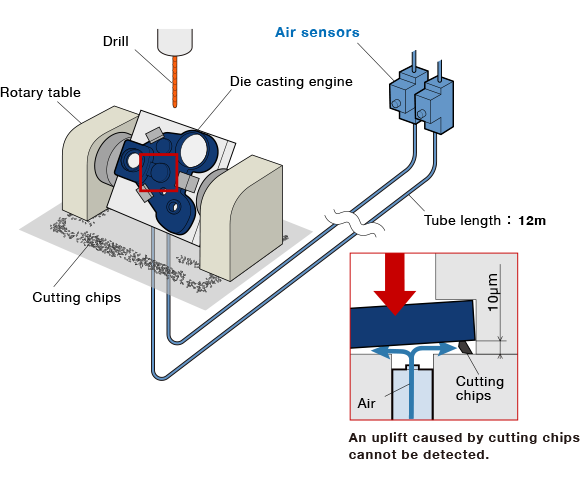

The client had a trouble with the small chips put between the "jig" and "engine" when chucking the die casting engine to the rotary table in cutting by CNC machining center.

The "Air sensor " has been used to confirm the adhesion of the engine, however, because of the low repeatability ±10μm, the uplifts by 10 μm cutting chips cannot be detected.

Also, "air sensor" is installed externally, so its air piping is long (12 m), which makes the response speed over five seconds and reduces the productivity.

Furthermore, to make the polishing process smoothly after cutting, the manufacturer needed the adhesion accuracy above 10 μm and inquired us after our sales representatives visited it for PR.

The main focus of the issues

A 10μm slight uplift caused by cutting chips should be detected.

The response speed takes more than five seconds, so faster response speed is needed for more productivity.

Metrol’s suggestions

Although "air sensor" adopted on machine tools as a standard equipment is used for detecting machined workpieces, in fact, the most air sensors are intended for "presence detection" of workpieces and not suited for precise "confirmation of adhesion".

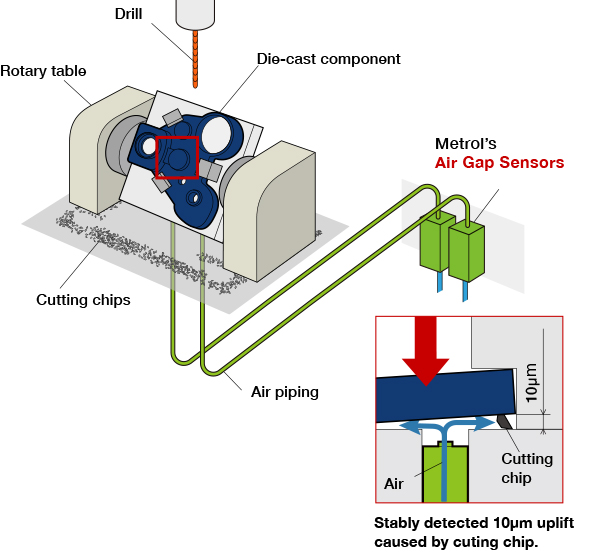

Metrol's "Air Gap Sensor" is a non-contact sensor which demonstrates ±0.5µm repeatability.

In addition, the sensor is resistant to harsh working conditions by IP67 protective structure, by installing it inside machine tool where cutting chips or coolant splatter.

・Air piping: 12 → 1.5m

・Response speed: 5 → 0.8 seconds

The considerable productivity of Air Gap Sensor has been realized.

Improvements

Stably detected a 10 μm of slight uplift caused by cutting chips.

The response speed was reduced to 0.8 seconds, and the productivity improved.

Comment from Metrol representative

Many of on-site engineers have said that "confirmation of adhesion" of workpieces by the "air sensor" intended for detecting a presence of workpiece impairs the accuracy and makes the precision machining difficult.

Like the cases introduced here, automotive manufacturers that require a high-accuracy "confirmation of ABS bar material chuck" of CNC lathe or "seating confirmation" in machining tire molds, etc. have adopted our products.

If you have any trouble in machining machine tools caused by involvement of "cutting chips", please feel free to contact us.

For further information about the products used in this application

Air Gap Sensor [Short range detection type]

A 10μm gaps due to cuttings chips can be detected stably!!

Enables accurate determination of seating and confirmation of adhesion.