Detection of CNC lathe processing point misalignment with ±0.5μm repeatability

Precision machining industry

The client is a manufacturer who produces precision components for HDD.

A representative of housing components section consulted us on "processing point" of CNC lathe.

Table of Contents

Client’s Issues

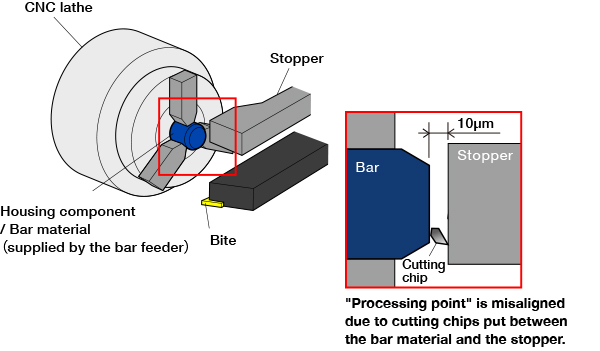

The client has a trouble with defective products caused by misalignment of the "processing point" when processing the housing components for HDD on CNC lathe.

Processing begins by feeding in the raw bar material and using the contact point with the stopper as the "processing point", but cuttings get caught between the bar material and the stopper and the position of the processing point becomes inaccurate.

Because the bar material is automatically supplied by the bar feeder, if the "processing point" is misaligned, all products become defective, leading to major problems.

He did a search on the internet, looking for a sensor which can detects "cutting chips" and found Metrol.

The main focus of the issues

A slight gap caused by cutting chips should be detected.

Need to prevent defective products due to misalignment of the processing point.

Metrol’s suggestions

Component machining accuracy at precision machining sites requiring high accuracy can be dramatically affected by minor 10μm cuttings.

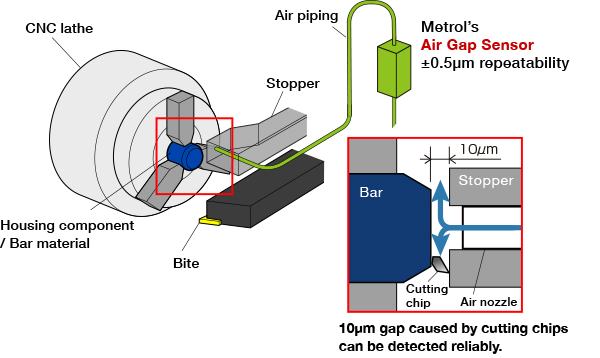

Metrol's "Air Gap Sensors" demonstrate ±0.5 μm repeatability which cannot be achieved with conventional "air sensors".

Embed an air nozzle in the stopper surface to detect "processing point" misalignment due to caught cuttings.

By stopping the machine automatically, it can prevent defective products.

Improvements

Stably detects the gap caused by cuting chips with ±1µm repeatability.

Defective product can be prevented by stopping the machine automatically.

Comment from Metrol representative

For "precision chuck confirmation" application of the CNC lathe, the use of Metrol's Air Gap Sensor and Dynamic's Palm Chuck has also enabled ultra-high precision processing of ABS automotive parts.

In addition, the IP67 protection structure allows installation inside the harsh environment of CNC lathe machinery, offering reduced response time for a sharp improvement in productivity.

If you have any troubles with defective products on CNC lathe caused by cutting chips, do not hesitate to contact us.

For further information about the products used in this application

Air Gap Sensor [Short range detection type]

10μm gap caused by foreign materials can be detected with contactless switches.

Precision seating confirmation of jig and workpiece can be realized.