Wirelessly confirm improperly set workpieces, preventing damage to machinery

Automobile industry

A motorcycle manufacturer that has a high share of the market both within and outside Japan.

We were approached by the manager of an engine unit producer with some questions regarding workpiece positioning on turret lathes.

Table of Contents

Client’s Issues

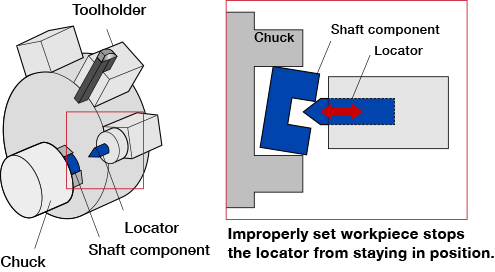

They used a turret lathe for the boring of crank shaft components;

however, improperly set workpieces were posing problems as they caused damage to the tool holder.

Shaft components were inserted into a locator before commencing machining,

but if the shaft set position was misaligned the locator didn't stay in position, causing damage to the tool holder when machining.

We received an inquiry through an internet search for a wireless positioning sensor that can be retrofitted to turret lathes to detect improperly set workpieces and prevent damage to the tool holder.

The main focus of the issues

Improperly set workpiece causes damage to the tool holder when machining.

Metrol’s suggestions

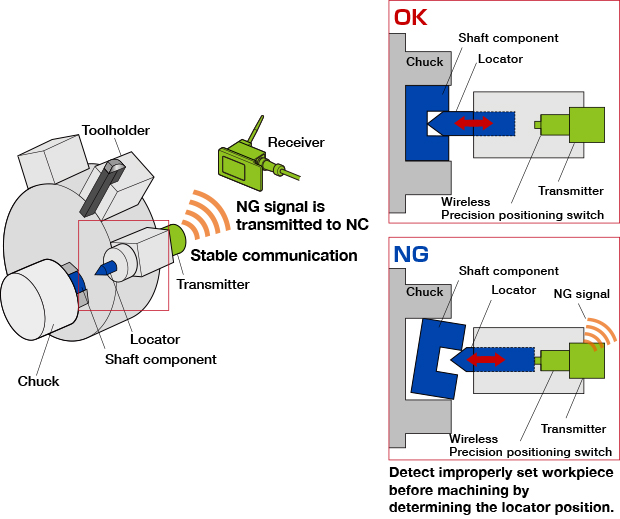

Metrol's Wireless Positioning Switch is ideal for positioning on turret lathes, where manipulating wiring is difficult.

Equip the Wireless Positioning Switch inside the locator to wirelessly monitor the workpiece position alignment.

By determining whether the locator is properly inserted into the shaft, improperly set workpieces can be detected before machining begins, eliminating damage to the tool holder.

Employing 2.4GHz FSK wireless system, Metrol's "Wireless switch" realizes stable communication without being interrupted by noise and obstacles in factories.

Improvements

Eliminate damage to the tool holder by detecting improperly set workpiece wirelessly.

Comment from Metrol representative

Production lines halting due to machinery failure results in not only the hassle and expense of replacement, but also large missed opportunities due to decreased productivity.

It is important to create a sensor-based positioning system to prevent large losses.

Please consult with us at Metrol to find a solution through wireless sensors within machine tools, or through internal machine measurement for detection of workpiece defects.

For further information about the products used in this application

Wireless positioning switch

Best suited for precise seating confirmation in 5-axis machining centers, pallet changers or rotary tables.