Corrected the Z-axis of a desktop robot in micron increments.

Industrial equipment industry

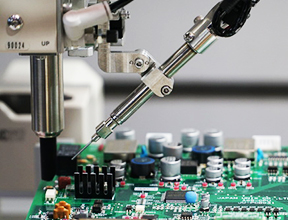

The client is a major manufacturer of desktop robots for electronic substrates.

An engineer in charge of designing desktop automatic soldering robots consulted us on "thermal displacement correction"

of the Z-axis of the solder head.

Table of Contents

Client’s Issues

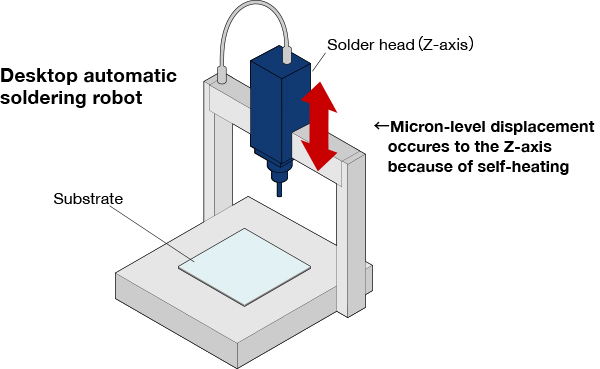

The client faced with a problem that the solder head position (Z-axis) deviates by microns because of self-heating, making precise soldering difficult and causing defective products.

We received an inquiry looking for a sensor that can detect the Z-axis position accuratly, having visited our website.

The main focus of the issues

Thermal displacement of the Z-axis of the solder head causes defective soldering.

Metrol’s suggestions

It is not easy to prevent reduction in positional accuracy due to thermal displacement caused by self-generation and differences between daytime and nighttime temperatures.

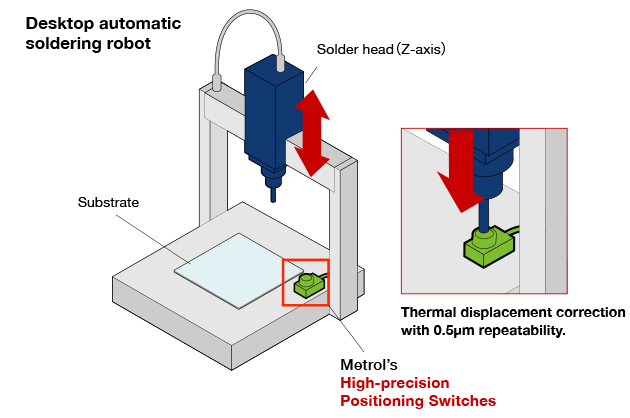

"High-precision Positioning Switch" can correct thermal displacement of the Z-axis with 0.5µm repeatability.

Precision and accurate soldering can be realized its precision mechanical switch structure.

Improvements

Thermal displacement of the Z-axis of the solder head can be corrected with 0.5µm repeatability.

Accurate soldering can be realized.

Comment from Metrol representative

Like this case, many robot manufacturers has adopted the "High-precision Positioning Switches" in applications such as "thermal displacement correction" of XY table or "positioning" of the height of bond nozzle.

If you are in trouble with the "thermal displacement" of your machines, please feel freet to contact us.

For further information about the products used in this application

High-precision Positioning Switch

0.5µm repeatability!

Able to correct thermal diesplacement in micron level because of precision mechanical structure that does not use any electrical component.