Eliminated the need for the intermediate actuator by replacing proximity sensors.

Industrial equipment industry

The client is a industrial device manufacturer.

A representative of the production engineering department consulted us on "existence detection" of the engine part during assembling.

Table of Contents

Client’s Issues

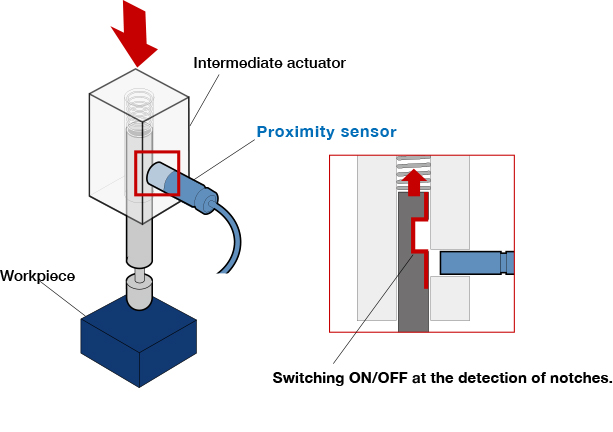

A "proximity sensor" has been used for the detection of the engine parts, however, an intermediate actuator was necessary for stable detection, and this caused problems of mounting space and cost.

The workpieces are made from various materials such as iron and stainless steel.

Since the detection distance of "proximity sensor" varies according to the materials, errorneous detections occur frequently without using an intermediate unit.

The actuator was needed so that the sensor can indirectly detect the exsistence of the workpirce.

However, arranging the intermediate actuator requires a lot of space for mounting, causing designing problems.

The main focus of the issues

Erroneous detection due to the object's materials.

The intermediate actuator requires a lot of mounting space.

Metrol’s suggestions

A "proximity sensor" is not suited for detection of workpieces made from various kinds of materials because its detection distance varies by 10µm according to workpiece's materials.

Therefore, an intermediate acutuator is required when detecting different kinds of workpieces with a proximity sensor.

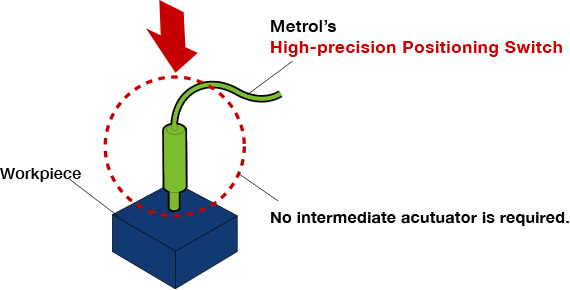

Despite that Metrol's "Precision Positioning Switch" is of the contact type ON/OFF switch, it demonstrates 5µm repeatability and has a durability of 10 milion operations.

Our switch directly touches the workpieces, so its object's materials do not matter.

Also, the contacting part can be freely customized so as to correspond to the various shapes of workpieces.

Improvements

Not affected by materials by stable workpiece contact detection.

Results in miniaturization of equipment by eliminating an intermediate acutuator.

Comment from Metrol representative

Although non-contact sensors like "proximity sensors" are popular for workpiece existence detection in production lines, their signal points vary according to workpiece's materials, which results in erroneous detections.

If you have any problems with workpiece existence detection, please contact Metrol.

For further information about the products used in this application

CS-Touch Switch

10 million contact life time with 5µm repeatability!

The best-selling positioning switches.