Thorough Comparison Of “Accuracy” In Switch Products! What Is The Key To Selecting The Best Product For The Purpose?

Table of Contents

Production goods have many similar products and it’s difficult to tell the difference.

Dear designers and engineers,

Have you ever had the experience of selecting parts on a mail-order website and wondering which one to choose because there are so many products for the same application lined up in a row?

Different manufacturers make different products, so there is no fair comparison of performance, and the price ranges vary widely.

There are few user reviews for production goods, and it is difficult to select the best product on your own.

Compare the actual performance of the switch products and identify the differences.

In this issue, we thoroughly compare the accuracy of [switch products], which are widely used by designers and engineers, between those made by METROL and those made by other companies!

Reproducibility results for each product are presented below.

A surprisingly clear "accuracy difference" was observed.

In order to design good equipment, it is important to find the right balance between price and performance and select the "right" product.

- I chose the one with the lowest price, but it does not fulfill its purpose due to lack of performance.

- Product specs were too high than necessary and extra costs were incurred.

To avoid such risks, please use this article to help you choose a switch wisely!

Notes. This data is for reference only. When using the product, be sure to check with the actual device.

What this article will tell you

Limit Switches / Micro Switches / Touch Switches

- Results and Verification of Accuracy Experiments

- Features and Differences of Switches

- Applications and uses suitable for each switch

Evaluation targets and experimental methods for repeatability testing

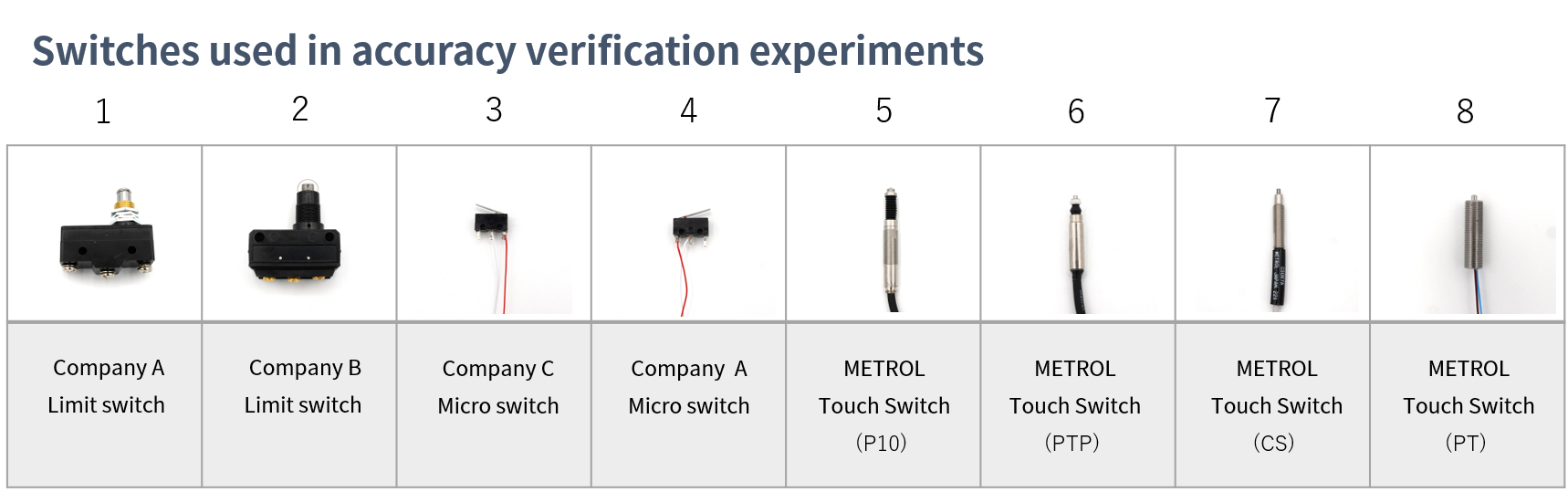

Products under evaluation

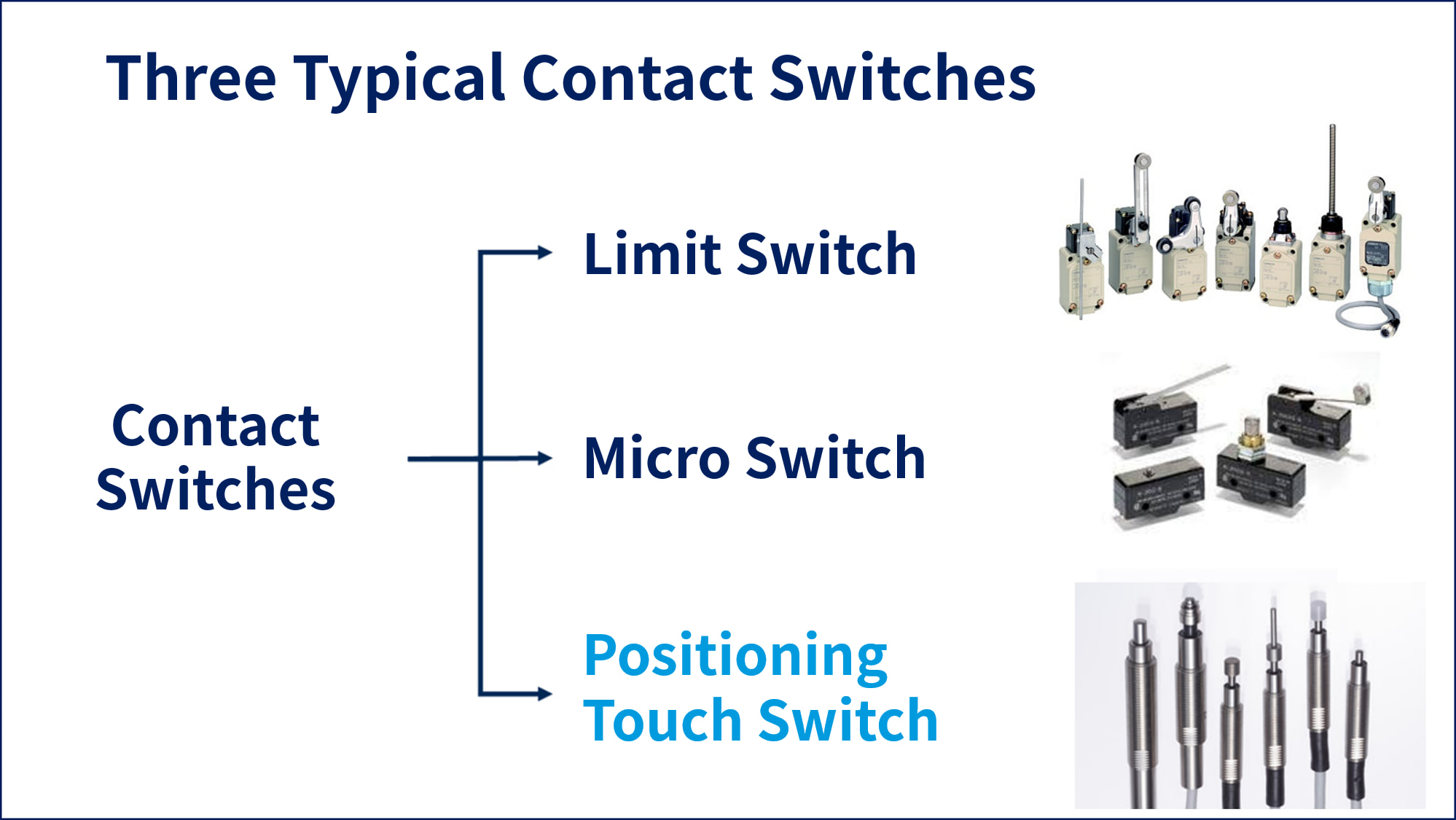

This time, we compared the accuracy of three typical types of contact switches.

- Limit switches

- Micro Switches

- Touch Switches (made by METROL)

These switches open and close electrical circuits and are used in many machines and equipment that detect the position of workpieces and objects under automatic control in the manufacturing field.

They come in a wide variety of sizes and shapes, and are a versatile type of sensor that can be applied to a wide range of applications.

Since they all have similar purposes of use, they are classified in the same category on mail-order websites.

* For a detailed explanation of the basic structure and features of limit switches and microswitches and their differences from touch switches, please refer to this article. What you absolutely need to know to avoid making mistakes with microswitches

Thorough comparison of 3 types of Limit / Micro / Touch switches

We purchased two limit switches and two microswitches of approximately the same size, made by several major manufacturers, from a mail-order website.

Four types of touch switches with different contact (measuring element) shapes were prepared from Metrol's products.

All eight types of switches were compared by measuring their accuracy using a repeatability tester.

Evaluation Environment / Conditions

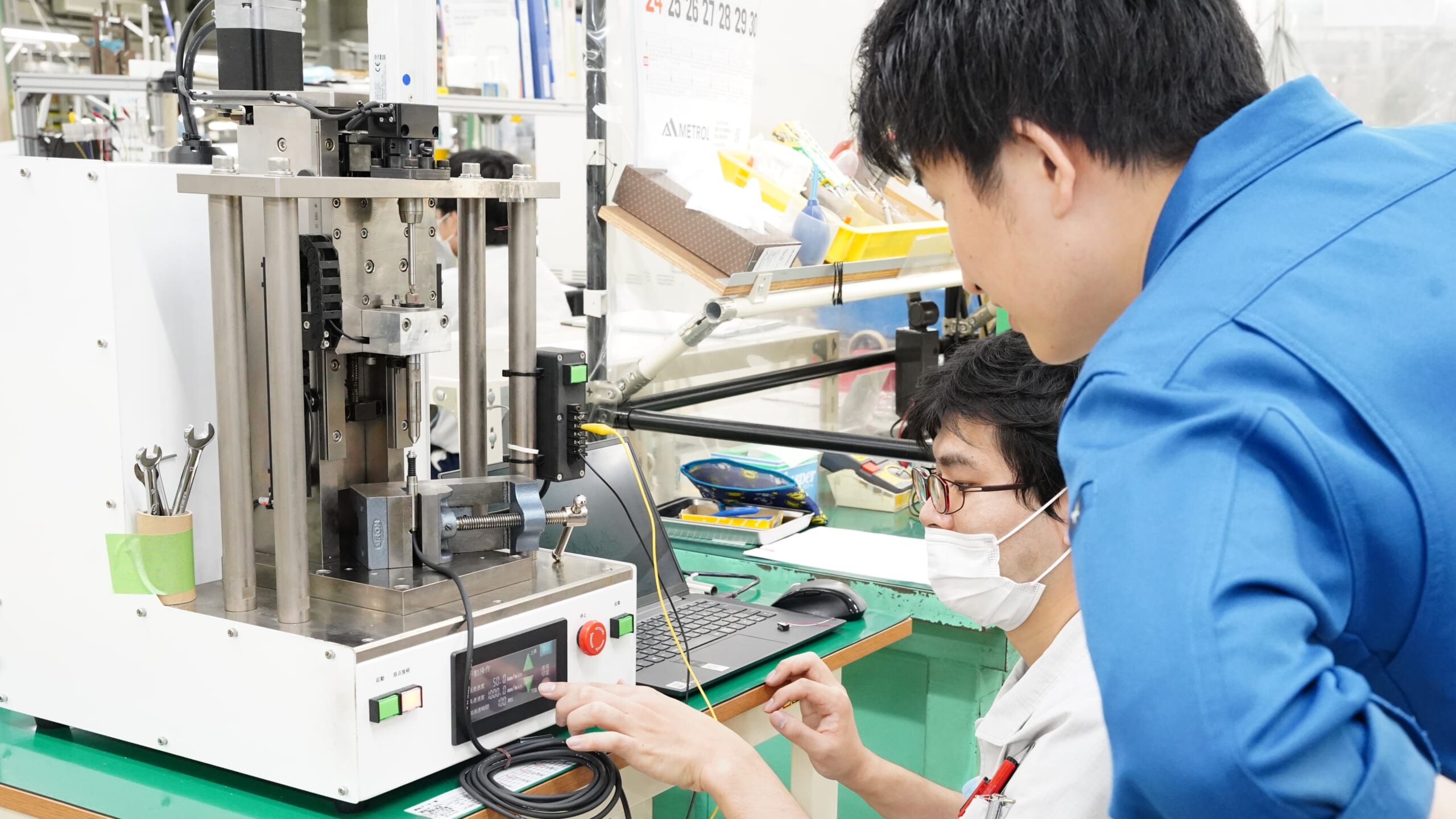

Comparative experiments were conducted under the following conditions

[Location]

In the METROL plant

[Equipment used]

Repeatability tester (*Used by METROL for pre-shipment inspection of products)

[Evaluation method]

The switch was fixed to a vise, and the operation of pushing in 0.1 mm and pulling out 4.0 mm from the signal switching point was repeated 50 times at a speed of 1000 mm/min on a repetition accuracy testing machine.

The first 20 cycles were initialized, and the subsequent 30 cycles were measured for repeatability.

Results of Accuracy Tests

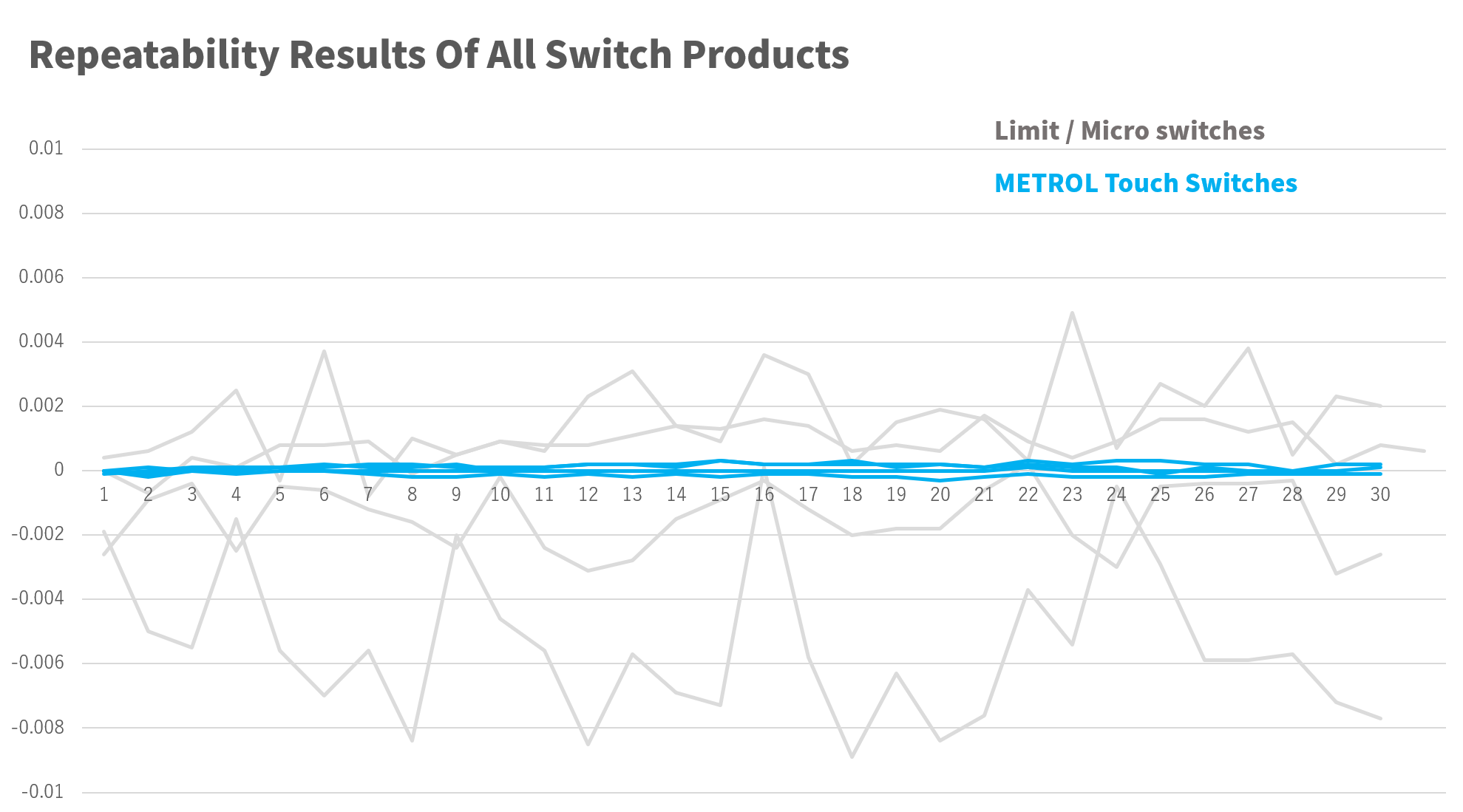

First, the values for all switches in the repeatability test are shown in the graph.

In a repeatability test conducted under the same conditions, METROL's positioning touch switches recorded the highest accuracy.

Next, the evaluation results for each product are described individually.

Repeatability Test Experimental Results

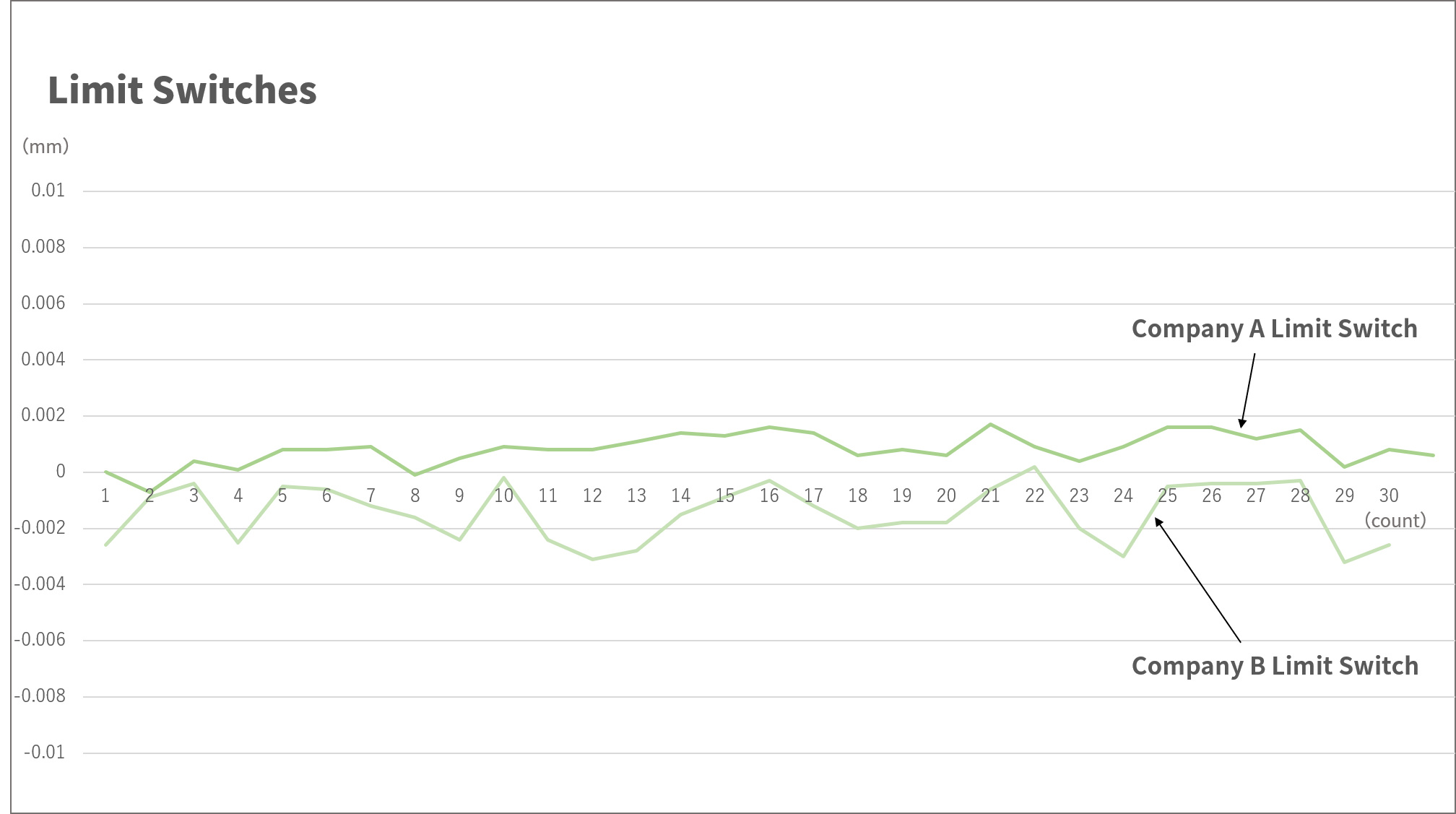

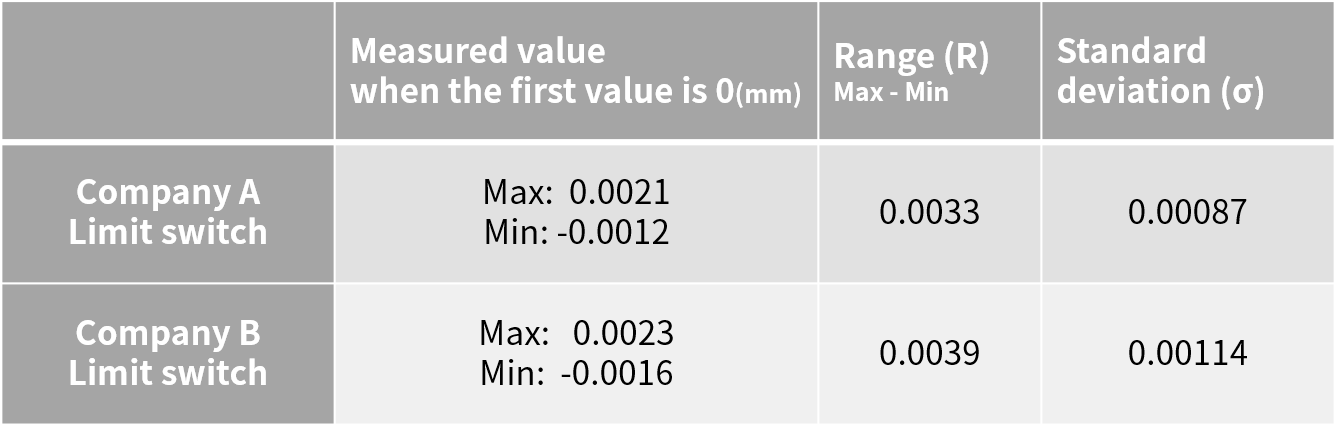

Limit Switch

*[SD: Standard deviation] is a measure of the degree of variation in measured values. ・Small standard deviation = small overall variation. (The distribution of measured values is clustered around a standard value of 0) ・Large standard deviation = large overall variation. (There are many measurements that are far from the standard value)

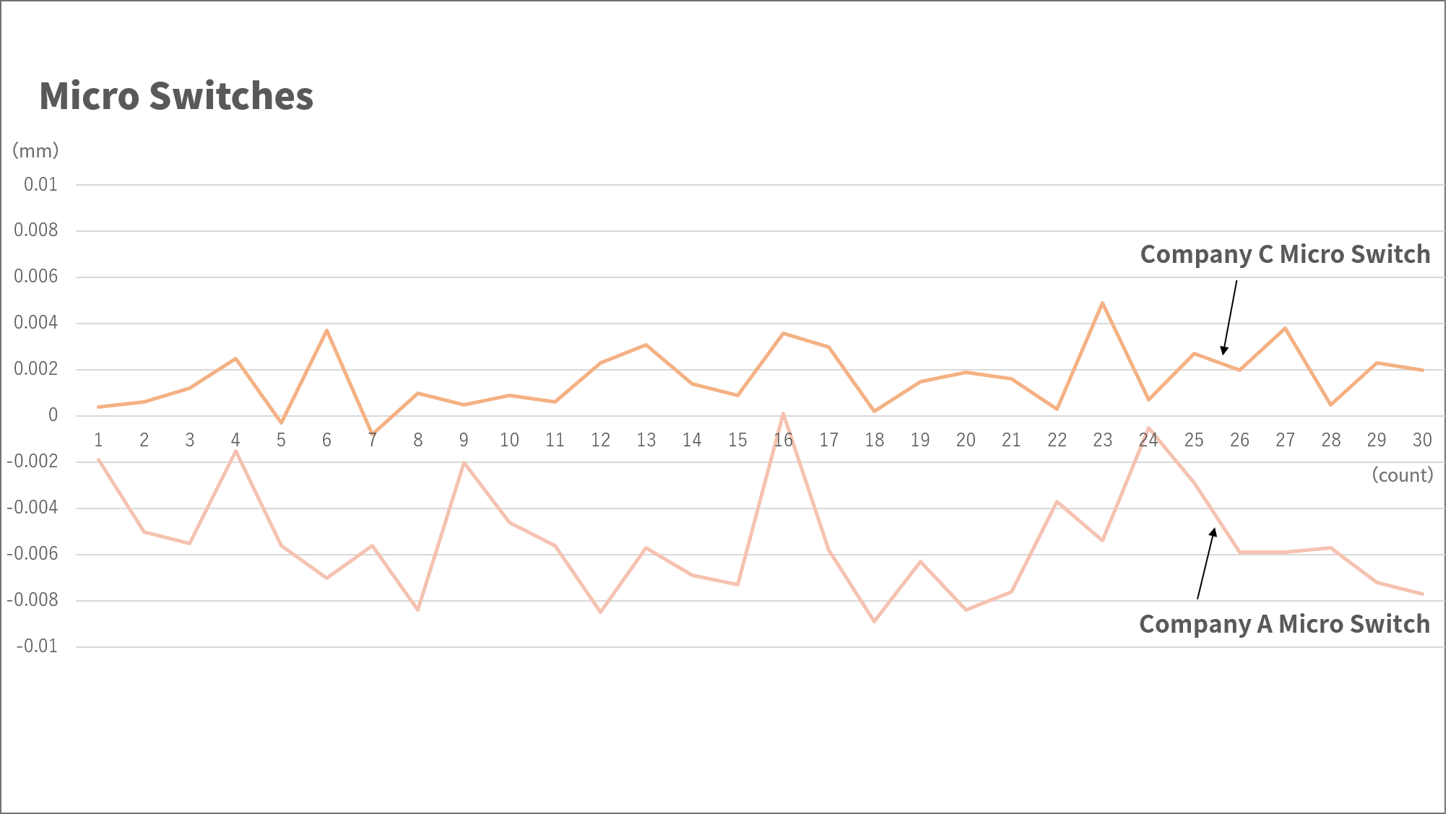

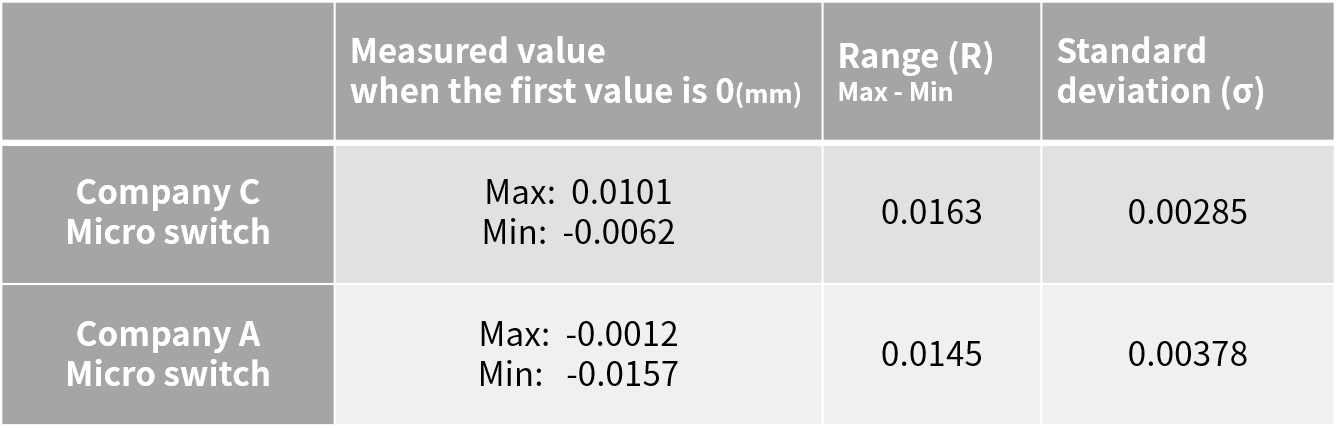

Micro Switch

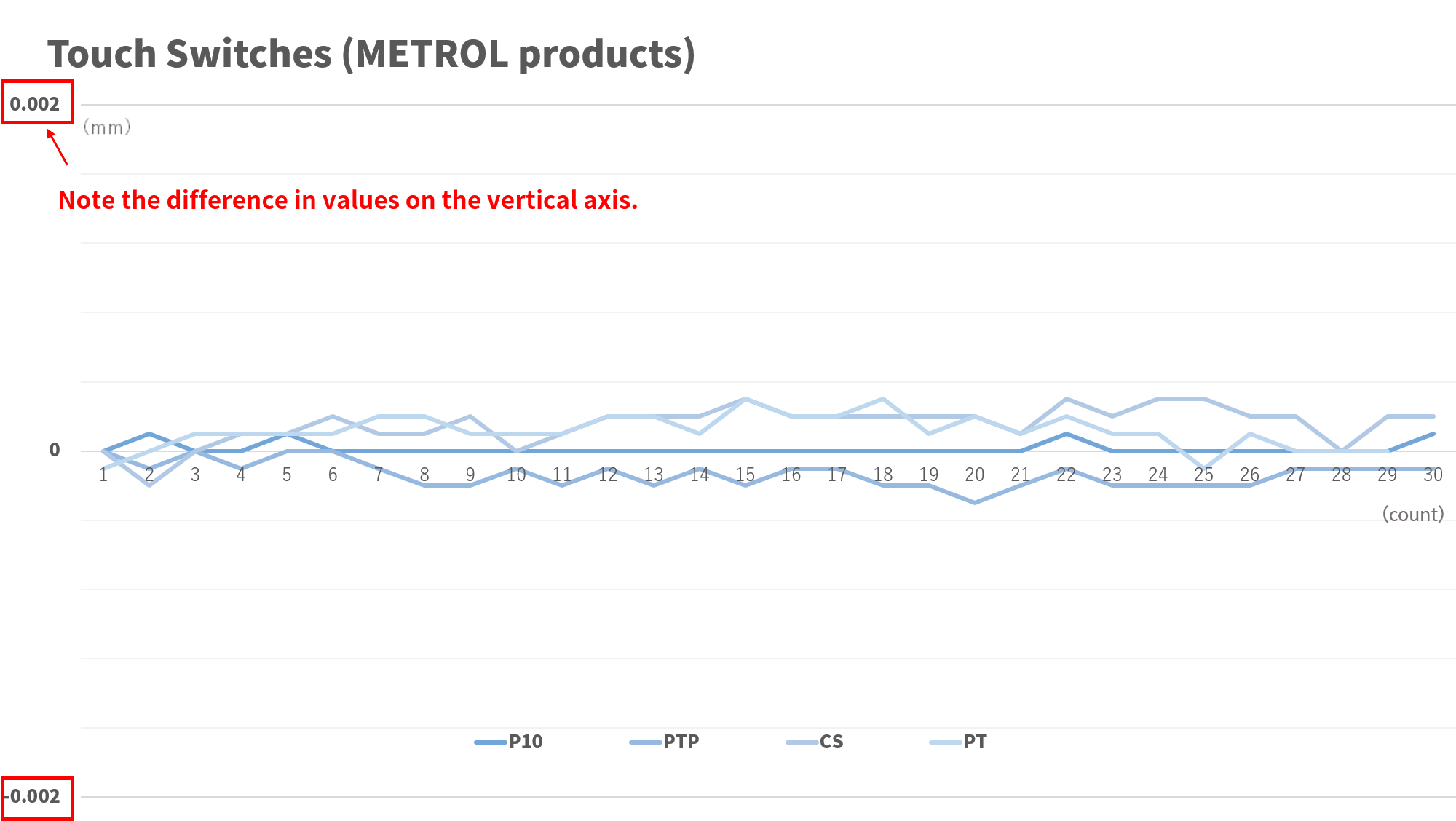

Touch Switch (METROL products)

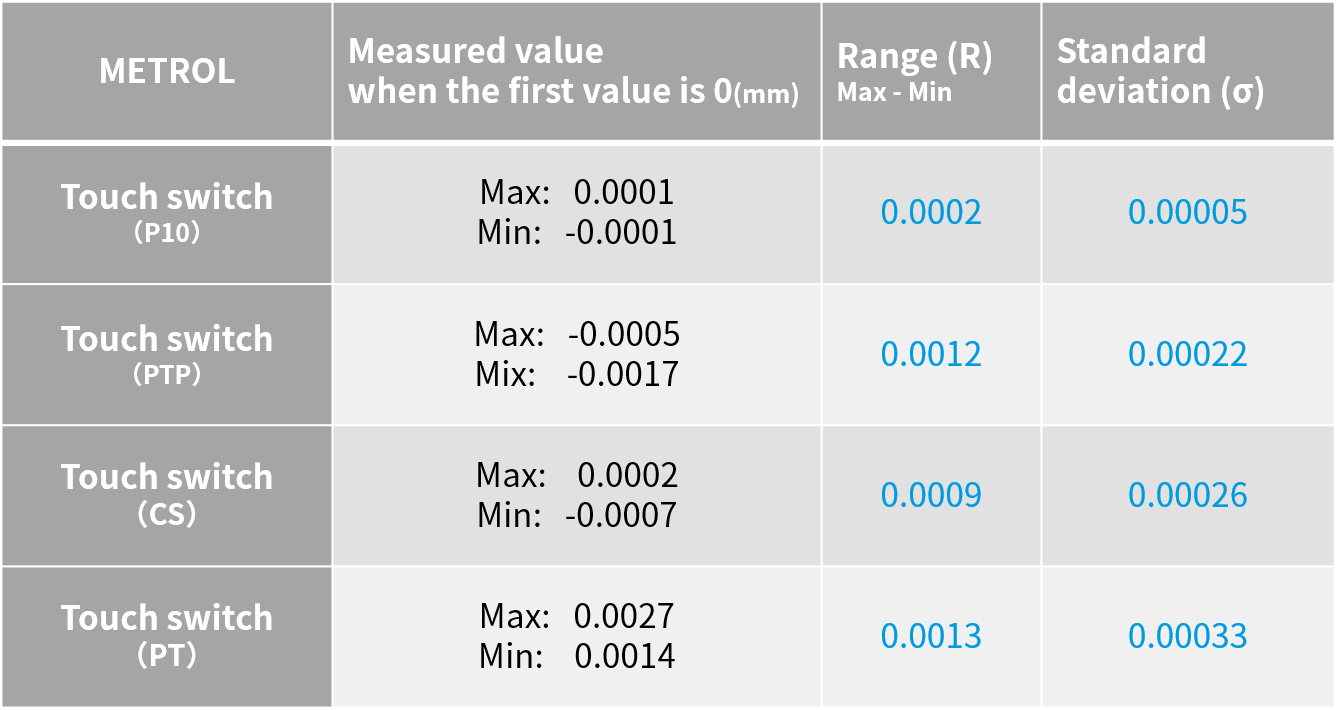

[Repeatability Test] Overall Evaluation

Overlaying the graphs for all products resulted in the above.

All four types of METROL's touch switches show little variation, and their high accuracy compared to micro switches and limit switches is obvious at a glance.

Case Studies of High Precision Touch Switches

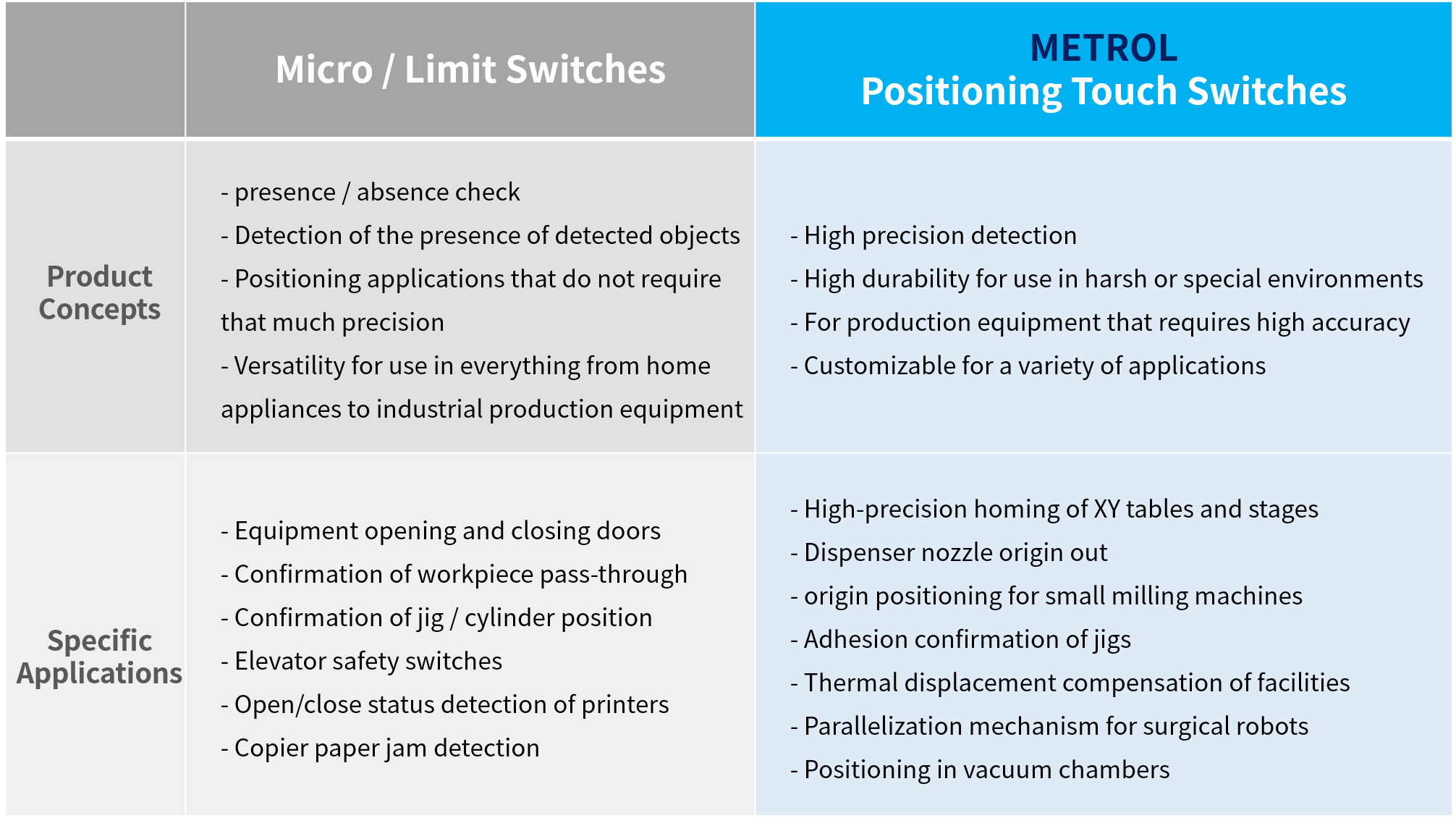

Touch switches are capable of precision positioning with higher repeatability than "presence/absence detection," and can be used to maximum effect in the following applications.

Case studies:

- Switches for high-precision homing of XY tables and stages (milling machines, 3D printers, chip mounters, etc.)

- Dispenser nozzle origin out

- Originating small-diameter tools

- Confirmation of jig and mold adhesion

- Correction of thermal displacement of equipment

- Parallel dosing mechanism for medical surgical robots

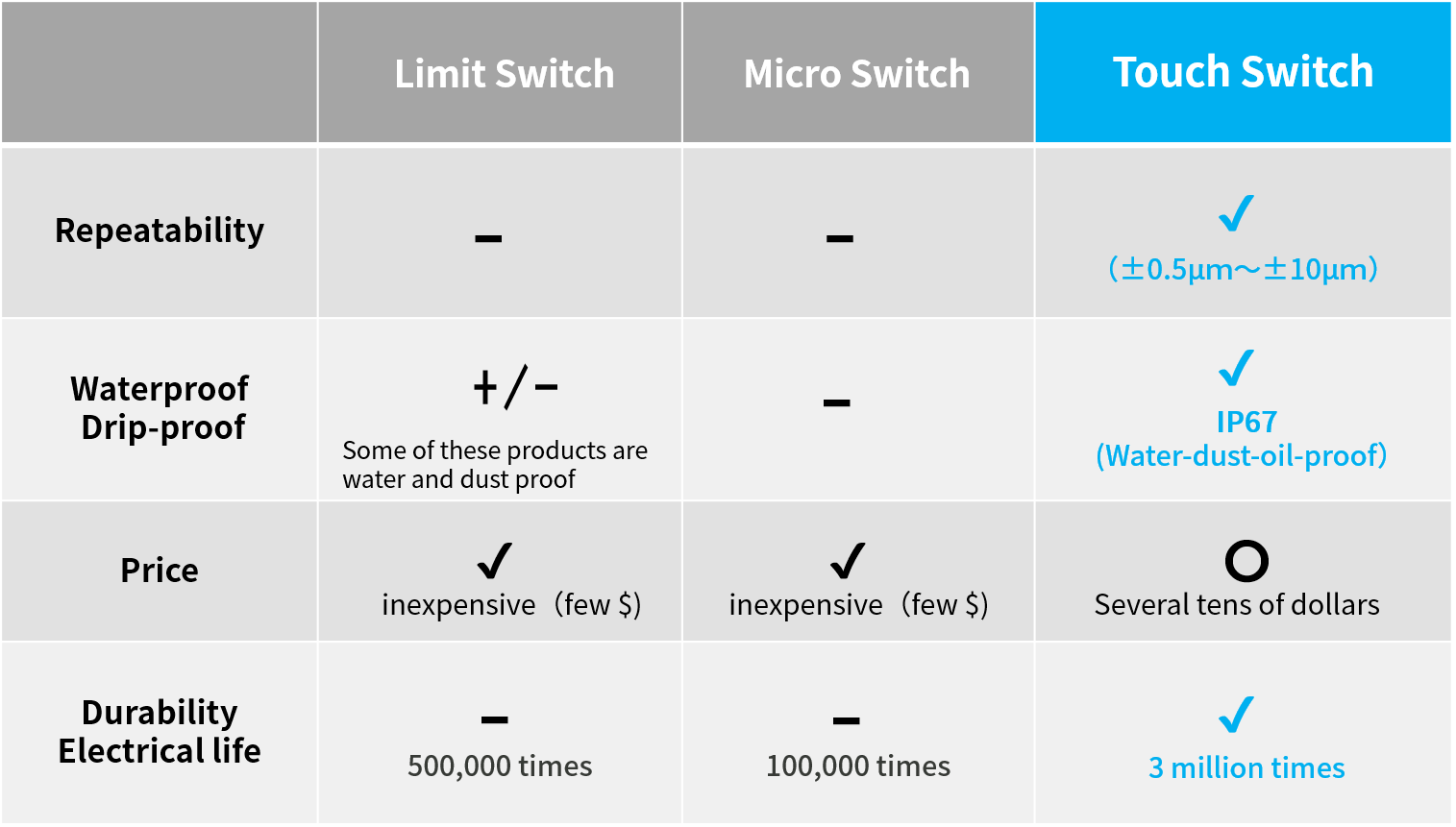

What Are The Product’s Features Other Than Accuracy?

So far, we have only compared the accuracy of each switch through experimentation.

In addition, we have also organized other factors to consider when making a purchase.

*Electrical life Endurance performance when the switch is turned on and off at the specified operating frequency with the load applied so that the voltage and current are at their rated values. When the switch passes current, the contacts wear out and eventually the current ceases to flow.

Conclusion

We hope you have understood from the experimental results that METROL's touch switches are 10 times more accurate than limit microswitches.

It is the best choice for purposes such as [fixture adhesion] and [equipment thermal displacement compensation], which require high accuracy in the micron range.

On the other hand, limit switches and microswitches have the advantage of being reasonably priced and cost effective for presence/absence detection applications that do not require such precision, although their accuracy is more variable than that of METROL's products.

As for limit switches, some of them have some degree of environmental resistance to water and oil because the built-in switch is covered with a cover.

METROL's touch switches are also available in a wide variety of products designed for use under more severe conditions, such as the following

・Heat-resistant type usable in high-temperature environments up to 200°C

・Low contact force type for detection of easily scratched or deformed workpieces such as semiconductors and ceramics

・High vacuum class compatible type made of low outgassing material

If you are considering using switches in special environments, please consider and consult with us about touch switches.

What level of accuracy and durability do you require from your switches? or Do you prioritize price?

Please select the most suitable switch after understanding the characteristics of each.

If the specifications and conditions of use are fixed, you can search by narrowing down with the button below.

METROL’s Switches Evaluated In This Article

① Ultra-compact, high-precision [PT series]

World's smallest size, high-precision series

The series features small size but high repeatability.

Even though it is ultra-compact with a diameter of φ5mm, it has a repeatability of 1μm and is often used in narrow spaces.

② High-precision, high-durability switch [MT series]

Achieves precise positioning and centering. Ultra precision touch switch

The MT series is our most accurate series.

Although the size is slightly larger, the built-in "bearing" demonstrates a high repeatability of 0.5 μm.

④ High cost performance switch [CS series]

The CS series is a best-selling touch switch that comes in a reasonable price range, with just the right size and a wide variety of shapes.

Feel free to contact us

Our engineers will respond to any questions regarding product usage methods or requests to customize products.

We can provide our best support if details about application, usage environment and what kind of workpieces will be detected can be provided.

Use our contact form below to contact us.

![① Ultra-compact, high-precision [PT series]](https://metrol-sensor.com/wp-content/uploads/2021/02/series_pt_image_3-400x400.jpg)

![② High-precision, high-durability switch [MT series]](https://metrol-sensor.com/wp-content/uploads/2021/02/series_mt_image_1-400x400.jpg)

![④ High cost performance switch [CS series]](https://metrol-sensor.com/wp-content/uploads/2021/02/CS-2-400x400.jpg)