Utilize Touch Probes with Robot Hand Exchange, Automate Workpiece Positioning and Measurement

Table of Contents

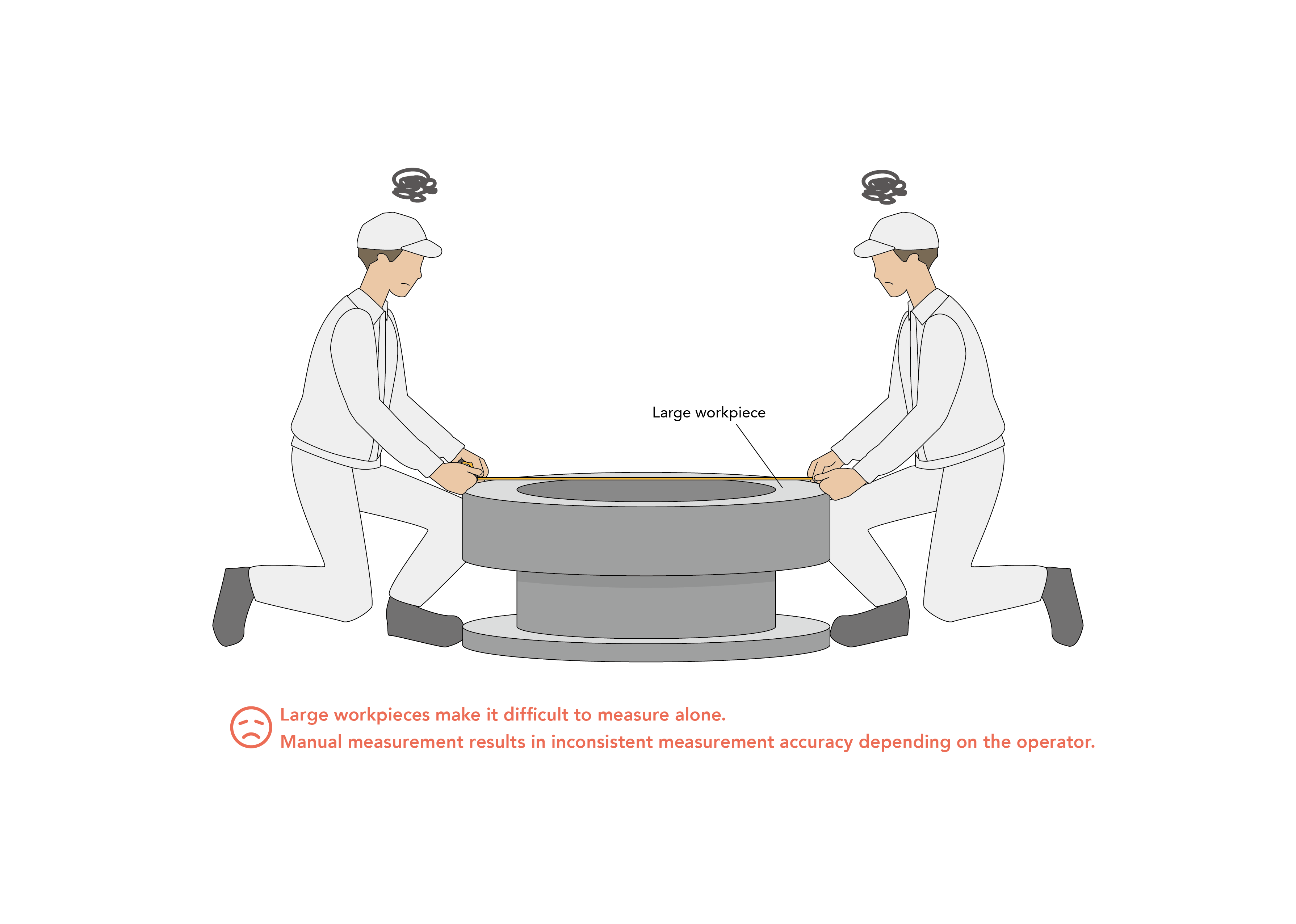

Client’s Issues

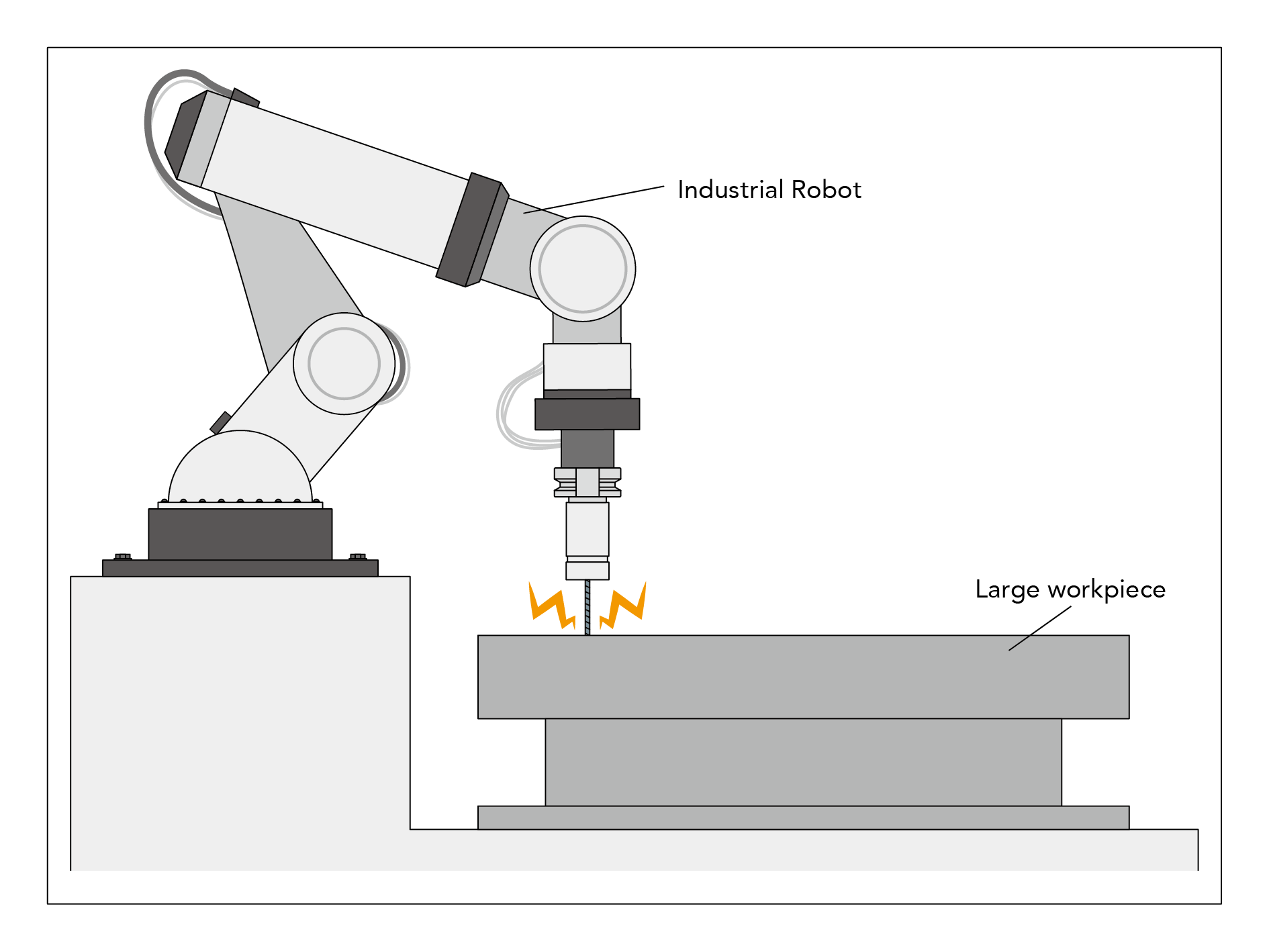

Large workpieces (EV battery cases, engines, etc.) and long workpieces (lumber, steel, etc.) were too large to be machined on CNC machines, but can now be machined using an articulated robot.

However, since the positioning of the workpiece and measurement after machining were done manually using a micrometer and a dedicated jig, the operator was troubled by the variation in measurement results and the time and labor required to take measurements.

The main focus of the issues

The workpiece is too large to be machined by a machine tool.

Manual work to set the origin of cutting and measurement after machining requires a great deal of man-hours.

METROL’s Suggestions

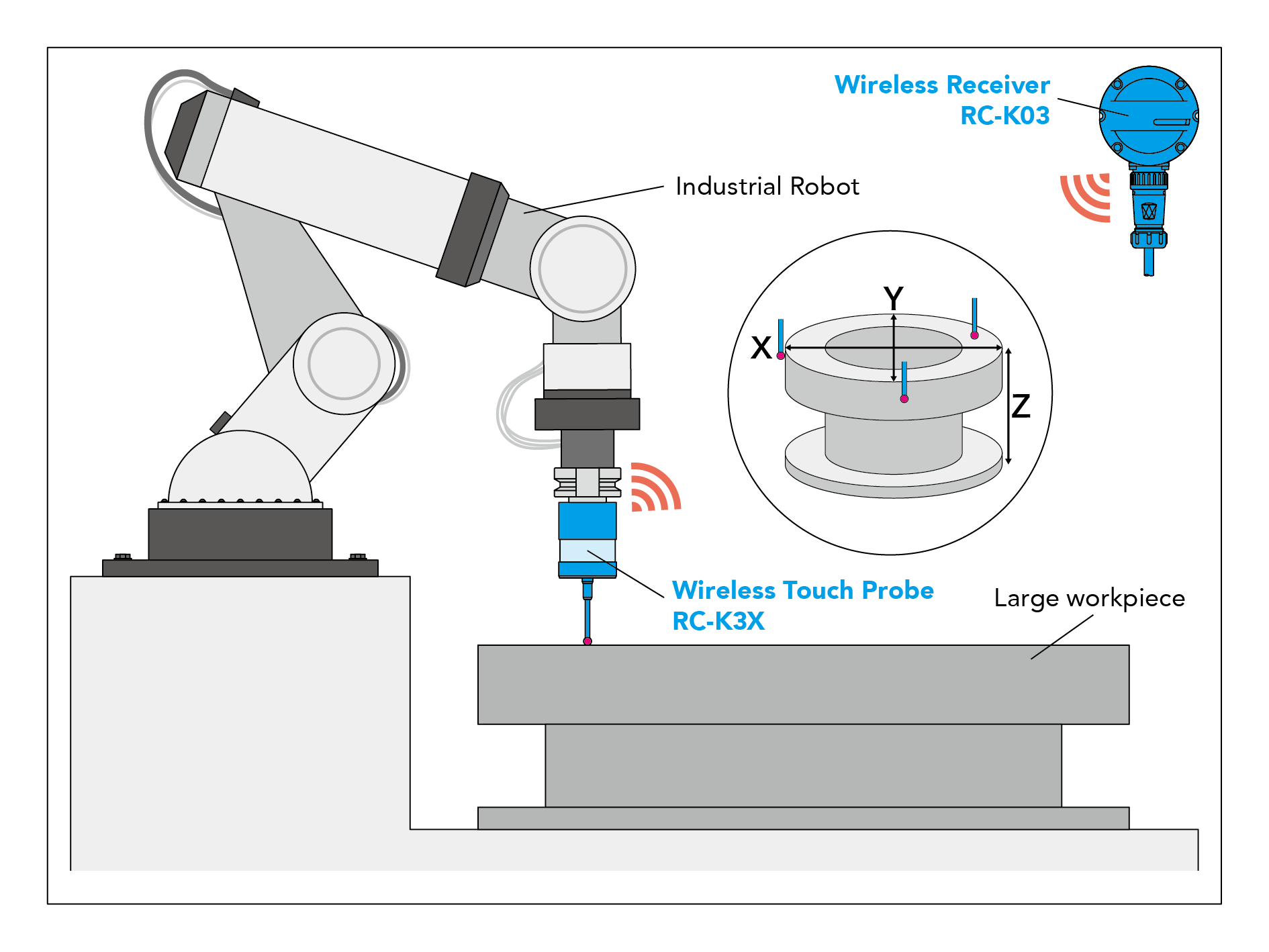

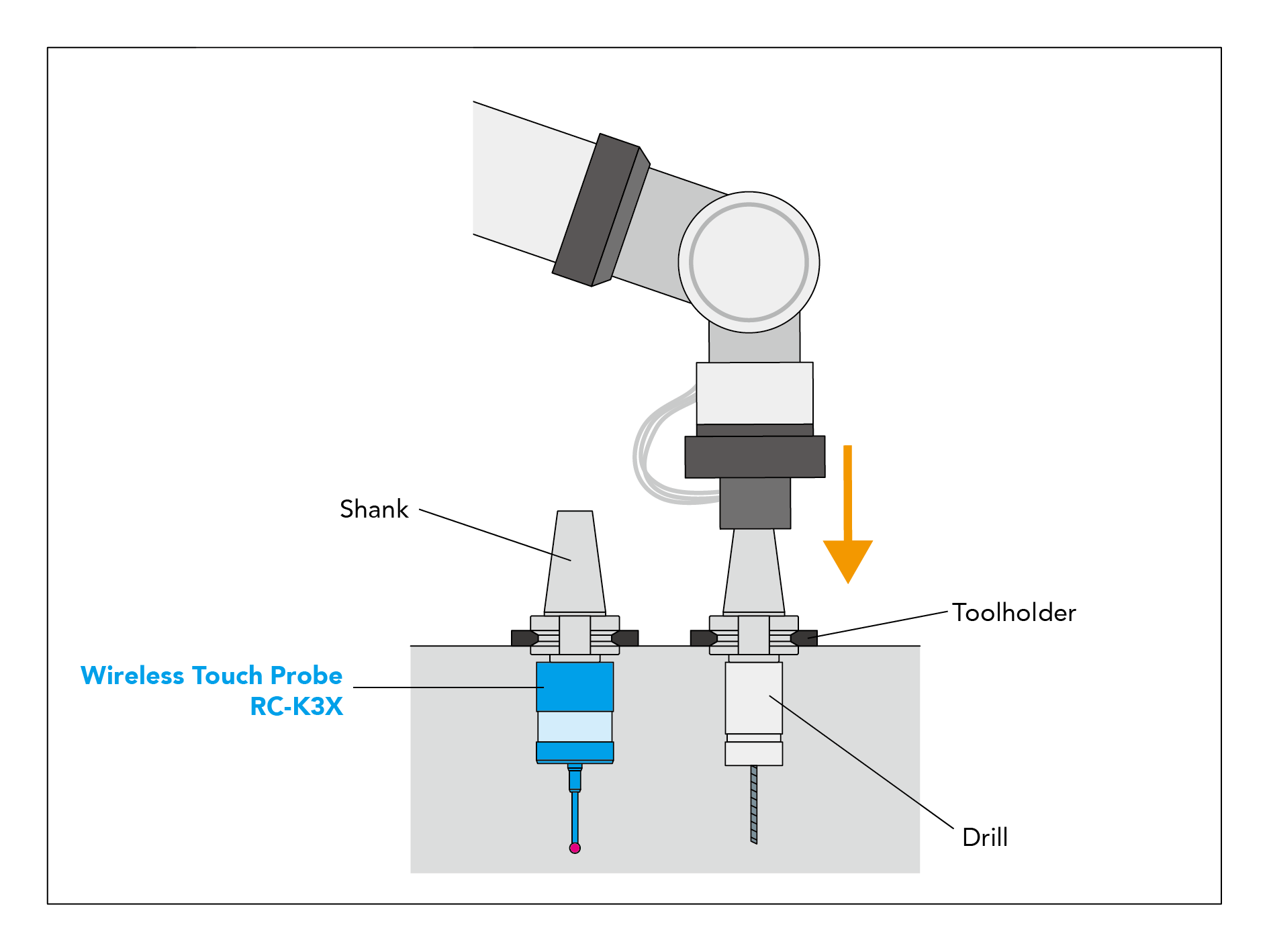

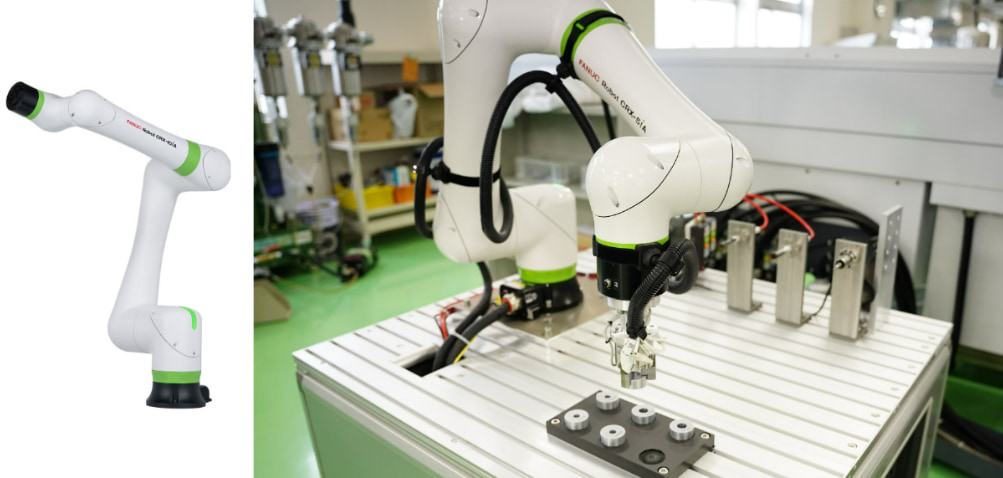

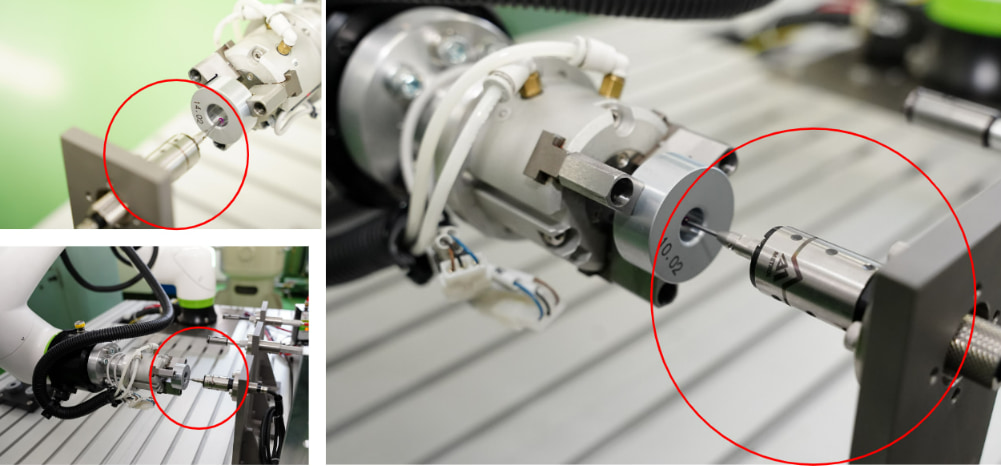

Utilizing a tool changer, the robot processes while changing between a drill and a touch probe.

With the introduction of the touch probe,

- machining origin setting

- post-processing measurement

were automated. By automating tasks that were previously performed manually, the number of man-hours required for measurement has been greatly reduced.

1.Robot hand is replaced by a Touch Probe to set the origin of the workpiece.

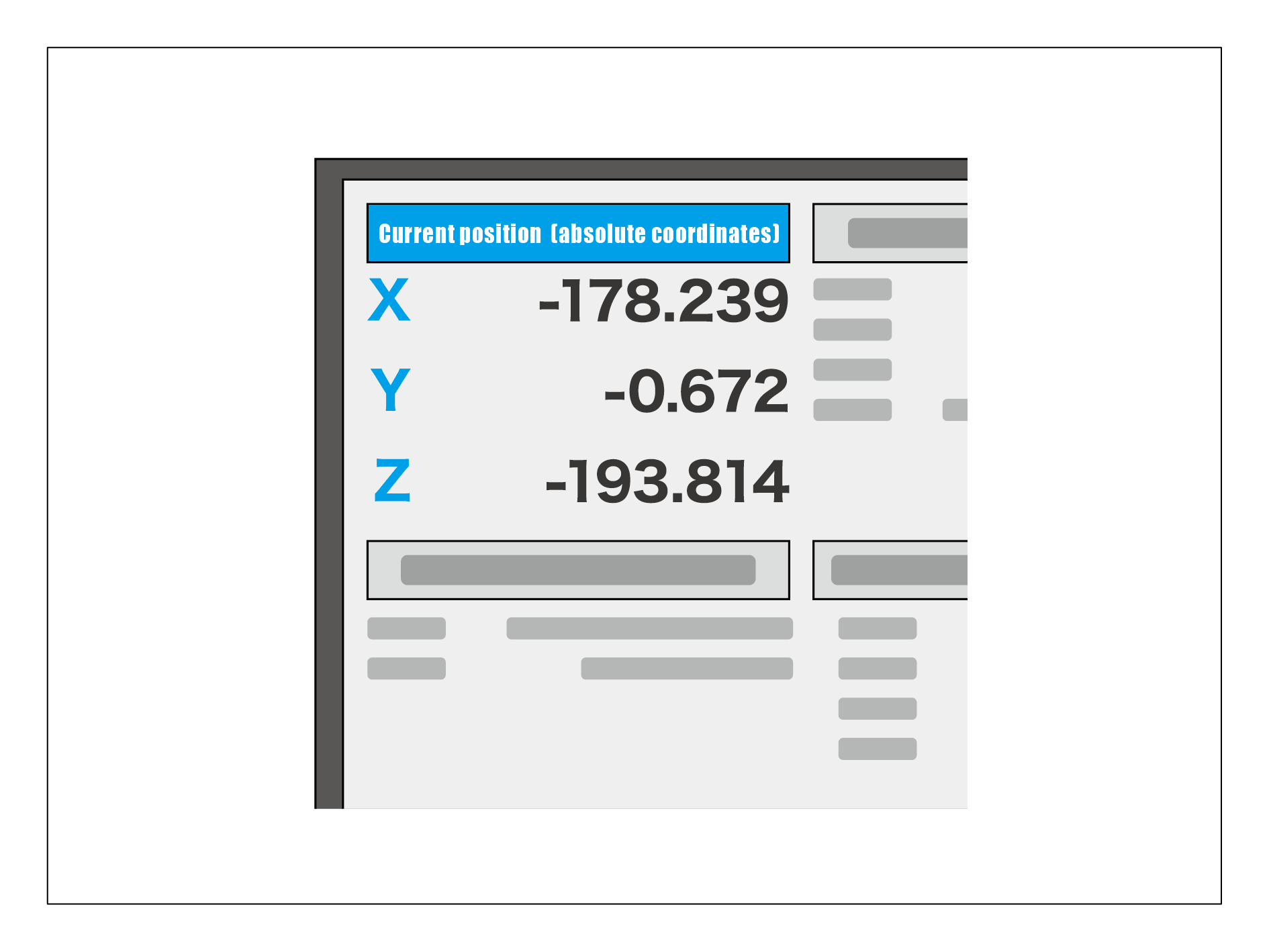

2. The coordinate position of the workpiece is displayed as a result of the Touch Probe measurement.

3.Robot arm switches between Touch Probe and drill

4.Machining workpieces based on position coordinates measured with a Touch Probe

Improvements

Increased accuracy of positioning the origin and improved machining accuracy.

Automation of post-machining measurement significantly reduces operator inspection man-hours.

Image of application

Comment From METROL Representative

An increasing number of companies are utilizing industrial robots with a variety of hands to perform multiple roles in a single machine, such as “polishing,” “deburring,” “drilling,” and “welding. By having the robot arm hold our Touch Probe, we have automated the robot so that the workpiece can be machined to the desired specifications for outer and inner diameter and height. There are many requests to automate measurement due to manpower shortage, and we are very pleased with our customers.

For further information about the products used in this application

Wireless Touch Probe RC-K3X

Wireless High-Precision Touch Probes for CNC Machine Tools

The RC-K3X series is a Japanese-made wireless 3D touch probe for positioning workpieces and measuring dimensions after machining on CNC machine tools and robots. Using wireless communication, the probe's measurement signal is transmitted to the machine by a receiver.

An Ultra-Compact, Wired Touch Probe Sensor K3S Series

Compact touch probe for use on automatic lathes, NC surface grinders and robots