[Case Study] How to Utilize Small Touch Probes with Small Milling Machines

This article presents a case study of a small wired touch probe and small tool setter at NS CNC, a Canadian manufacturer of small milling machines.

Company Info. : NS CNC Manufacturing Ltd.

NS CNC is a developer and provider of high-precision mini CNC milling machines.

Especially utilized in the jewelry, watchmaking, and microfabrication industries, NS CNC’s unique technological capabilities have enabled the company to develop machines capable of machining intricate designs and details. Representative milling machines include [Mira 6S] and [Elara], which offer excellent performance for 4- and 5-axis milling operations. They also offer custom machines and accessories, offering solutions tailored to custmer’s needs.

NS CNC's ELARA2 series compact milling machine was installed with our sensors.

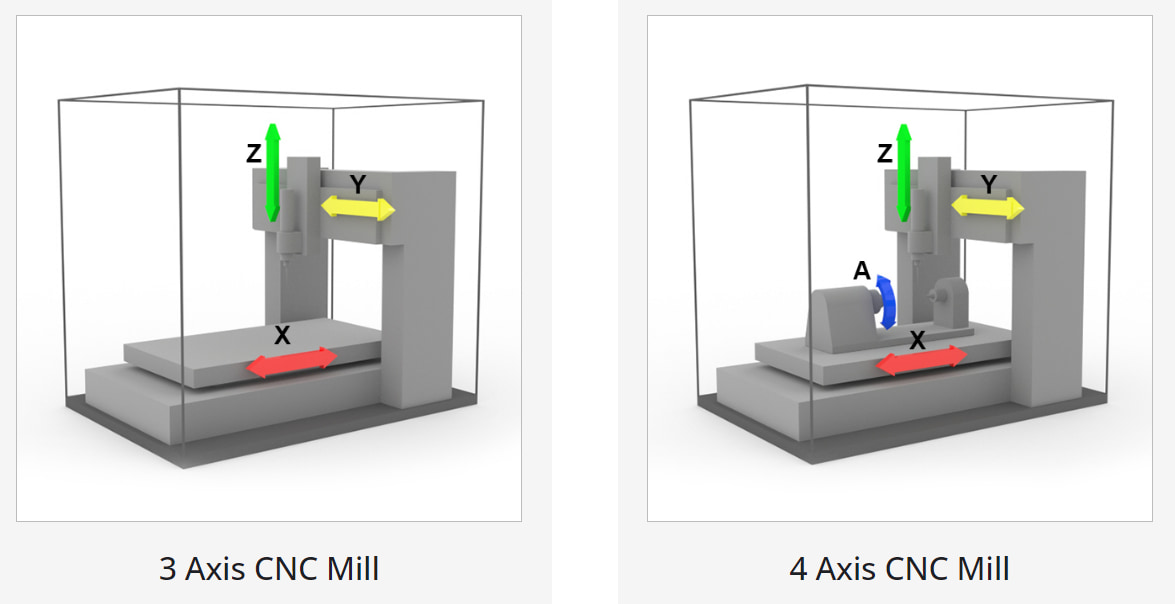

NS CNC's ELARA series of milling machines, available in 3-axis and 4-axis models, ensure stability for large, heavy workpieces and minimize vibration for precision machining.

Table of Contents

Challenges for NS CNC

When selecting a sensor for the ELARA series of milling machines, NS CNC asked us to

- [Application 1: Tool measurement] Detection of small-diameter tools with a tool diameter of 0.3 to 0.5 mm.

- [Application 2: On-machine measurement of workpiece] positioning workpiece before machining.

On the other hand, the customer had a design problem in that the machining space was small and the space to install the sensor was extremely tight.

Challenges

want to install a sensor for tool and workpiece measurement, but the mounting space in the machine is too small and cannot find a small sensor.

METROL’S Proposal

We proposed the following sensors to meet the design challenge of a narrow machining space and extremely limited space for mounting sensors.

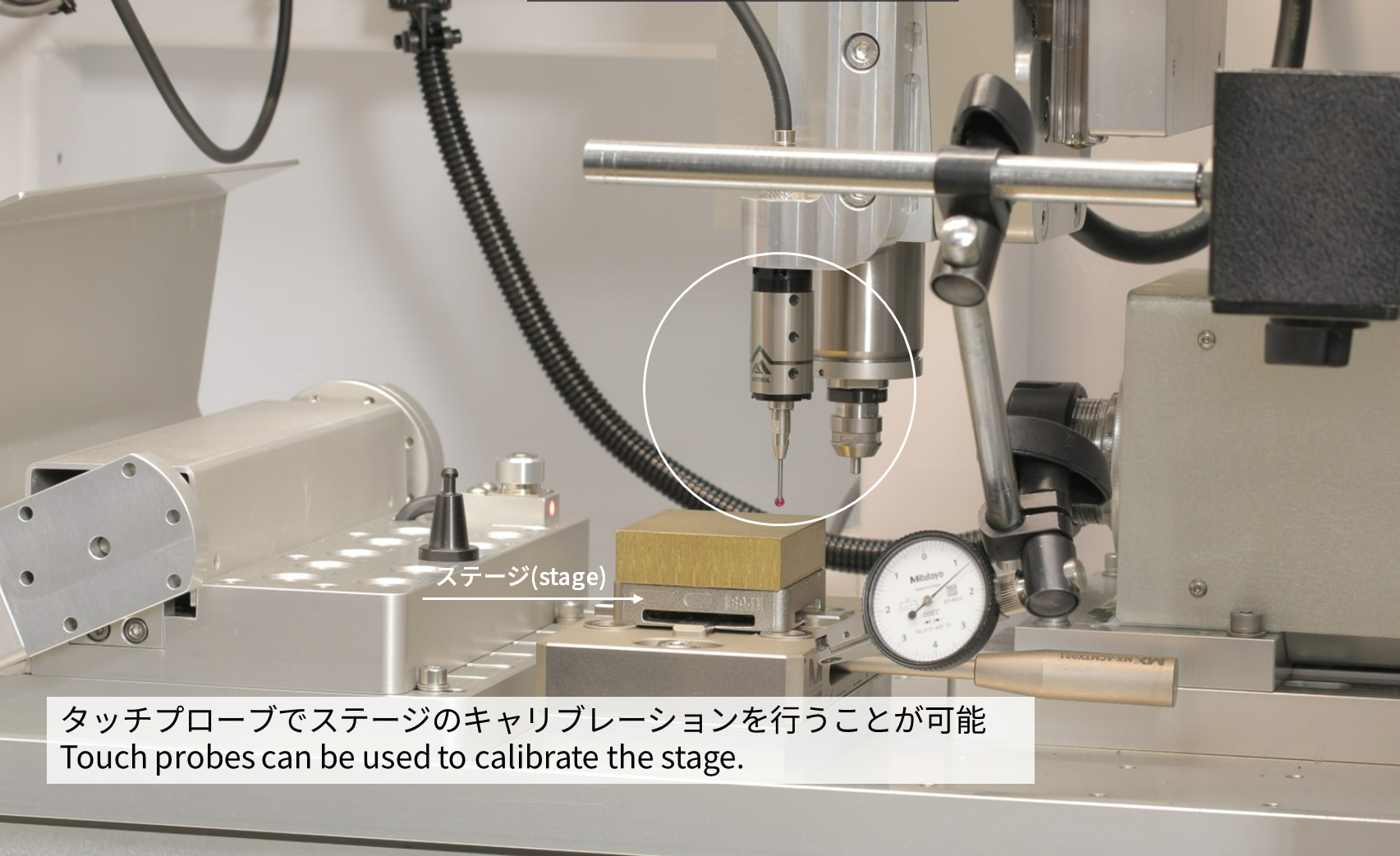

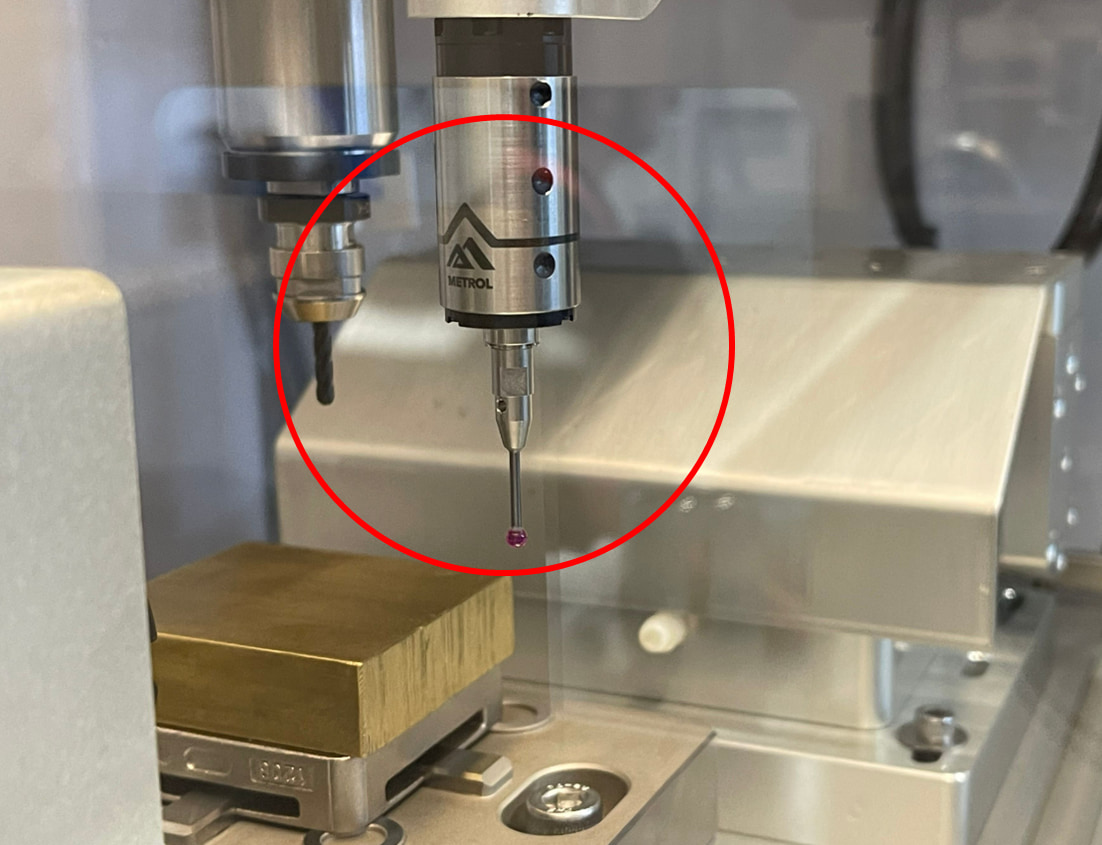

[For on-machine measurement] An ultra-compact, wired touch probe K3S series

Designed with the industry's smallest. Ultra-compact touch probe for use inside tight machines.

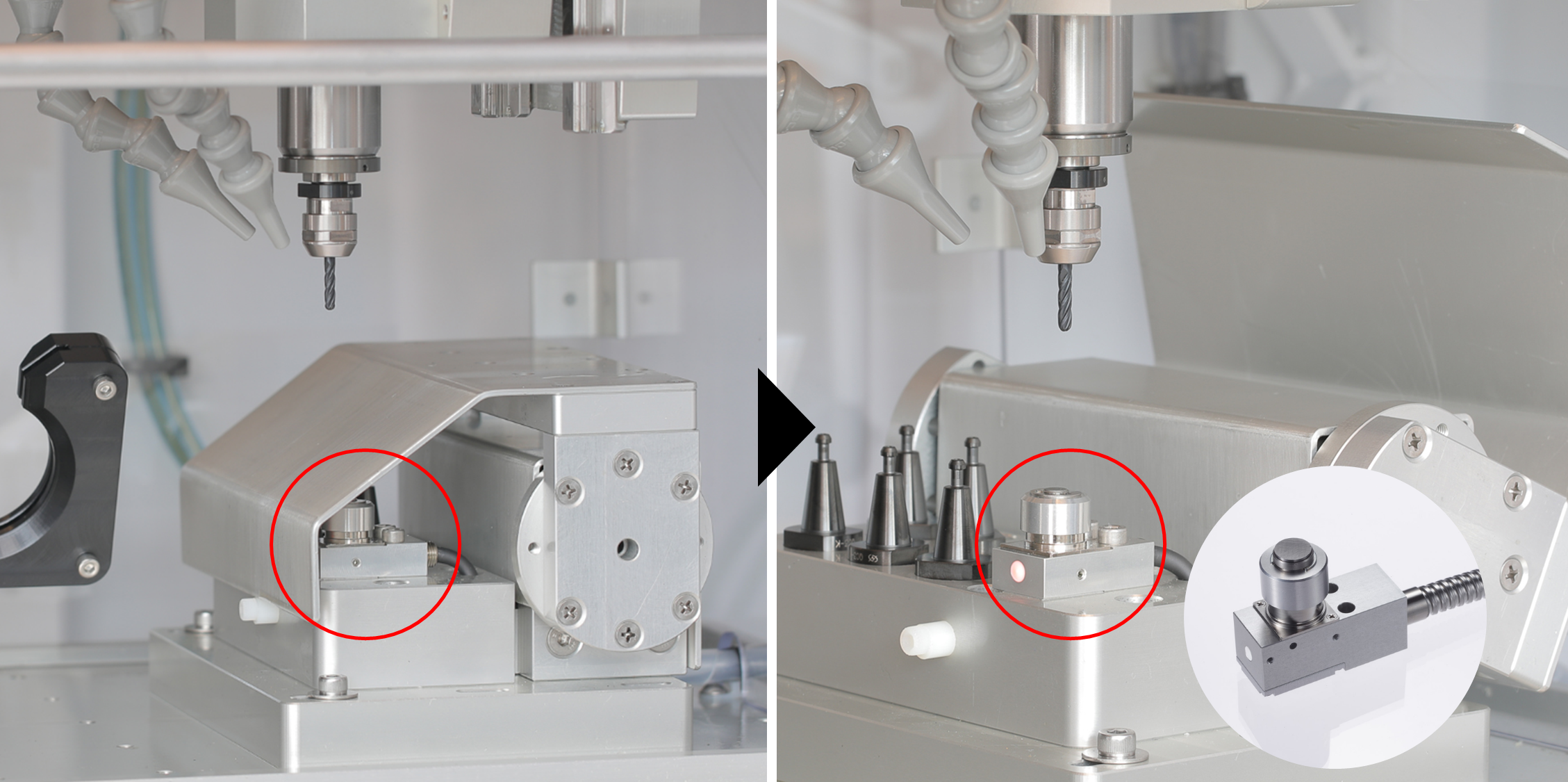

Tool setters for small machining centers and milling machines

The P21 series is a compact tool setter with an overall length of 45 mm and a height of 41 mm. It comes with an overtravel signal for collision prevention.

These two sensors boast the smallest size in the in-machine measurement industry and can be easily installed in tight spaces. Despite their small size, they achieve a repeatability of ±0.5μm to 1μm, maximizing their machine accuracy even on small milling machines.

In particular, the Tool Setter P21 has been used in many dental milling machines around the world.

Image after sensor installation

Case Study: Compact Touch Probes K3S Series

Case Study:Compact Tool Setter P21 Series

Results

Workpiece positioning has been automated, reducing setup man-hours.

Machining accuracy has improved due to highly accurate workpiece positioning.

Machining accuracy has been improved by being able to compensate for tool wear and thermal mutation.

Sensors featured in this case study

[For on-machine measurement] An ultra-compact, wired touch probe K3S series

Designed with the industry's smallest. Ultra-compact touch probe for use inside tight machines.

Tool setters for small machining centers and milling machines

The P21 series is a compact tool setter with an overall length of 45 mm and a height of 41 mm. It comes with an overtravel signal for collision prevention.

![[For on-machine measurement] An ultra-compact, wired touch probe K3S series](https://metrol-sensor.com/wp-content/uploads/2025/05/K3S_4c-3.png)