[Case Study] Evolving Robotic Machining.

Automate Cutting and Grinding of Large Castings

~Changing the Future of Heavy Labor with Robot, Touch Probe, and Active Compliance Force Control~

Table of Contents

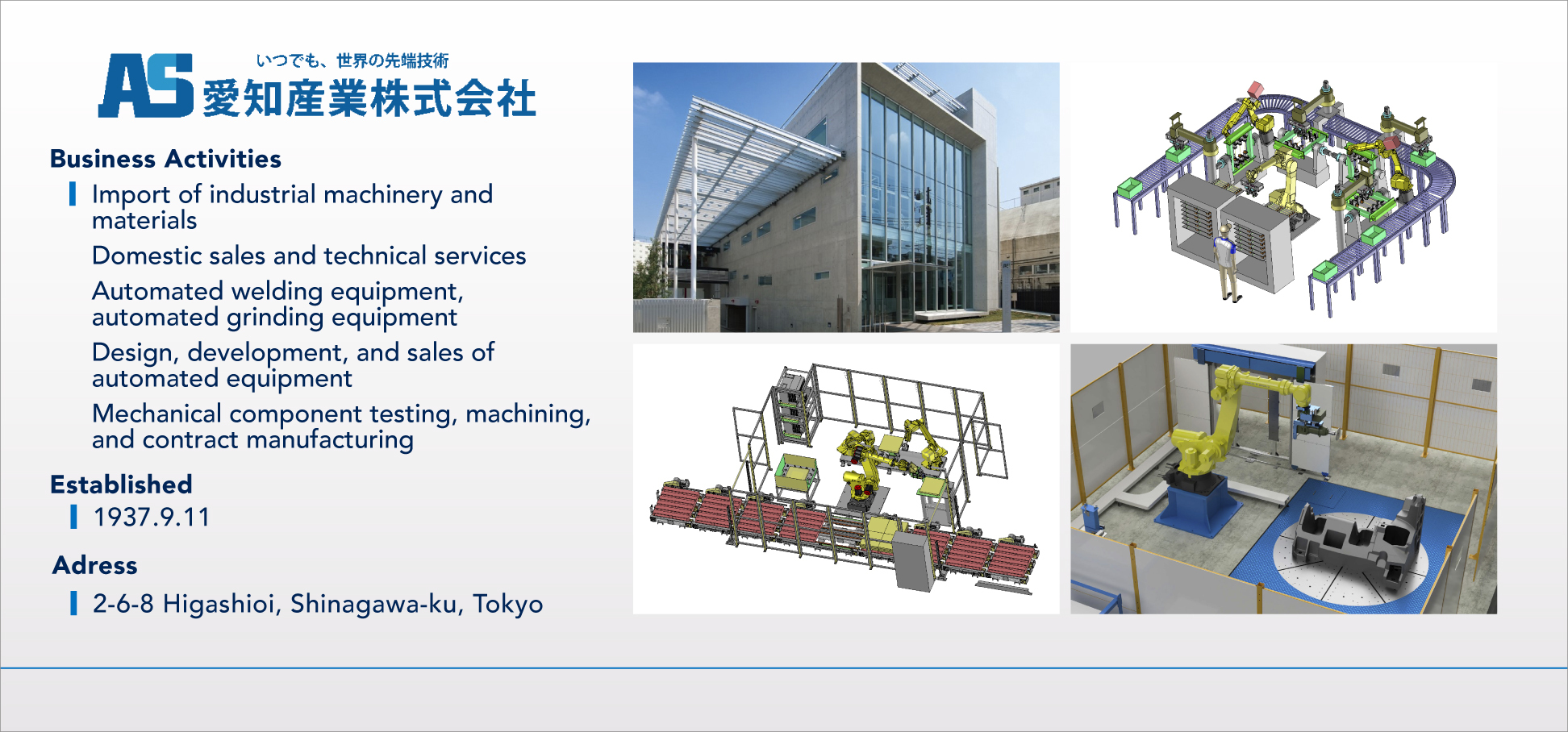

Interviewee: Aichi Sangyo Co., Ltd.

The interview was conducted in cooperation with Aichi Sangyo Co., Ltd. in Shinagawa, Tokyo. (Honorifics omitted below.)

In addition to its main business of importing and selling production goods, the company also excels at proposing solutions through technical development and support.

The company operates a variety of businesses, but in this article we will feature the Engineering Headquarters (Sagamihara Office), which handles robotic systems integration. It imports welding machines, machine tools, and metal 3D printers as a trading company, but its greatest strength lies in proposing automation solutions that combine advanced products with robotics.

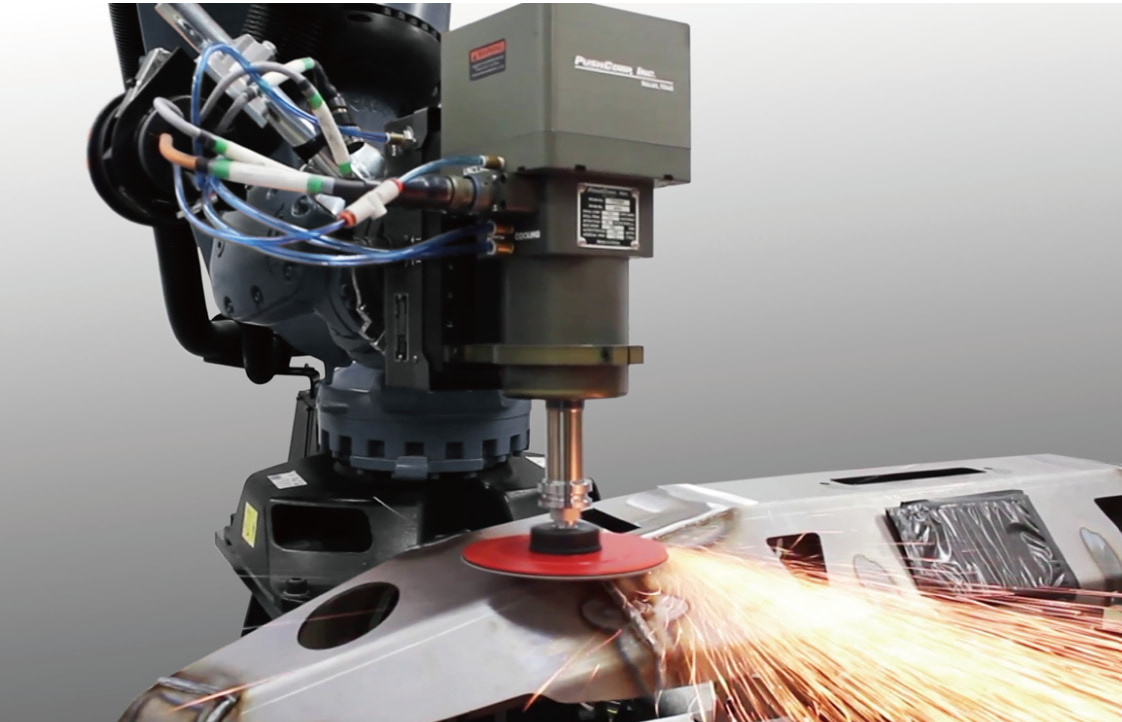

One example that embodies the company’s approach is its proposal utilizing the “Active Compliance Force Controller Device” manufactured by the American company PushCorp. Metals can be machined by mounting the PushCorp device on an industrial robot and attaching abrasives, cutting tools, mills, etc.

The PushCorp device consists of a sliding mechanism capable of adjusting and maintaining constant pressure in any position, and a servo spindle that comes standard with a BT shank.

The sliding mechanism incorporates force, acceleration, and position sensors. When the spindle's tip tool touches the workpiece surface, it feeds back input from these sensors to compensate for variations in load due to orientation, thereby maintaining consistent pressure.

As a result, even if there are variations in the accuracy of robot trajectory or the outer dimensions between workpieces, the PushCorp device can flexibly make adjustments and complete the machining. The device also features a compact size despite its high rigidity.

However, in order to fully utilize the PushCorp device, robot teaching and peripheral equipment are required. Aichi Sangyo has an Engineering Headquarters System Manufacturing Department that functions as a system integrator, with a proven track record of delivering integrated systems.

Kotaro Takemoto, a leader of the Mechanical Design Group in the department's Design Section says,

“We have adapted flexibly to customer requests and specific workpieces to be machined. Recently, there is a growing momentum in our automation projects for machining large workpieces and performing hazardous operations.”

Challenge: Cutting and grinding of large castings

Recently, the company was consulted about the automation of cutting and grinding for large castings.

Each casting is unique. Since the shape and positioning of each workpiece varies, alignment relied on the keen eyes and intuition of skilled workers.

This work imposed significant burdens on workers, including:

- High risk, as operators directly handle cutting machinery

- Human errors leading to inconsistent quality

- Time-consuming handling of large and heavy workpieces for processing

- Extended tool changeover and teaching time

- Inability to realize high-mix, low-volume manufacturing

With a declining number of skilled workers, maintaining conventional approaches is no longer sustainable.

Solves the challenge with an innovative robotic machining system utilizing a touch probe and active compliance force control

The solution introduced to take on this challenge is a robotic machining system that combines PushCorp's active compliance force controller device with Metrol's wireless 3D touch probe, the “RC-K3X.”

1. Mount the touch probe attached to the BT shank onto the PushCorp device

The workpieces to be cut are heavy and transported by overhead cranes in the factory, making high-precision positioning difficult. Creating dedicated jigs for positioning is also impractical, as the shapes of high-mix, low-volume products vary with specifications, etc.

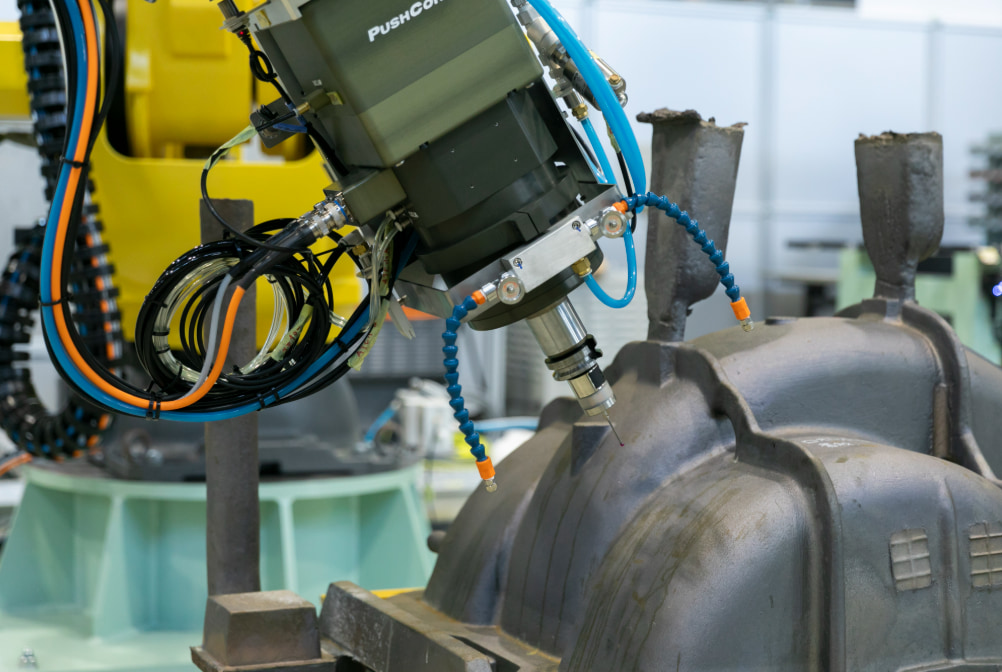

Therefore, we adopted the following method: place the workpiece on the workbench before machining, attach the RC-K3X touch probe onto the PushCorp device at the tip of the robot arm to measure the workpiece, determine its fixed position, and correct the machining program accordingly.

2. Origin setting by touching the workpiece at 4 points with the touch probe

After attaching the touch probe, the workpiece is touched at 4 points and origin setting is performed based on the measurement data. The cutting trajectory is automatically corrected to flexibly adapt to workpiece variations and misalignment.

3. Change the tool from the touch probe to a tip saw to cut the casting sprue

After that, the touch probe is switched to a tip saw to cut off part of the iron casing that houses the impeller of the LNG pump.

The casing is made by combining two semicircular castings of approximately 1 meter in width, depth, and height. Excess material like sprue remaining from the pouring process is removed by this robotic system.

4. Change the tool from the tip saw to an offset grind stone to grind the cut area

An allowance of approximately 10mm is left to avoid damaging required parts of the workpiece. Finally, the tip saw is switched to an offset grind stone to grind and finish the cut area.

PushCorp's active compliance force controller enables various tools to be pressed against consistent pressure, accommodating workpiece shapes and surface irregularities to achieve safe and stable cutting and grinding.

The traditional process of “manually moving, measuring, cutting, and grinding” has changed to a process of positioning with a touch probe and automatic cutting and grinding with a robot.

[Reference Video] Robotic machining innovation made possible by a touch probe and active compliance force controller device

Why METROL’s touch probe RC-K3X was chosen?

BT Shank Compatibility

PushCorp's servo spindle uses a "BT shank," a standard tool holder, to attach various tools. For example, this system uses a BT40 shaft taper. In contrast, the RC-K3X is also compatible with BT shank, and the fact that it could be purchased and used as-is was a major deciding factor.

Wireless design for easy integration

Another key factor is that it is wireless. Robots have a high degree of freedom in moving parts, making it difficult to route cables with wired types.

Even in locations prone to interference from Wi-Fi/Bluetooth or surrounded by obstacles that can hinder accuracy, the RC-K3X achieves stable repeatability of 1μm (2σ) through highly reliable wireless performance that is based on a proprietary communication method.

Contact measurement that is not affected by surface roughness or metallic sheen

The contact measurement method was also a decisive factor. Laser-based measuring devices were also considered, but a contact-type device was chosen to avoid potential interference from external factors such as the surface roughness and metallic sheen of castings, as well as brightness within the factory.

The contact-type device was also useful even when fine-tuning the operational program while actually moving the robot. Since it is viewed from outside of the safety fence, fine-tuning is made by operating the teaching pendant from a distance.

Even under such circumstances, the contact-type RC-K3X makes it easy to visually confirm physical contact with the workpiece.

Affordable price and reliability unique to Japanese manufacturing

The affordable price and reliable support system unique to Japanese manufacturing were also decision-making factors.

“At an exhibition, METROL's employees gave us a proposal, and the results of our evaluation were very good. The price was affordable, and since it's a domestic manufacturer, we felt confident in their support system, so we decided without hesitation,” said Leader Takemoto, sharing these encouraging words.

Many users experience touch probes malfunctioning due to collisions. This makes affordability a crucial factor for sustainable operation.

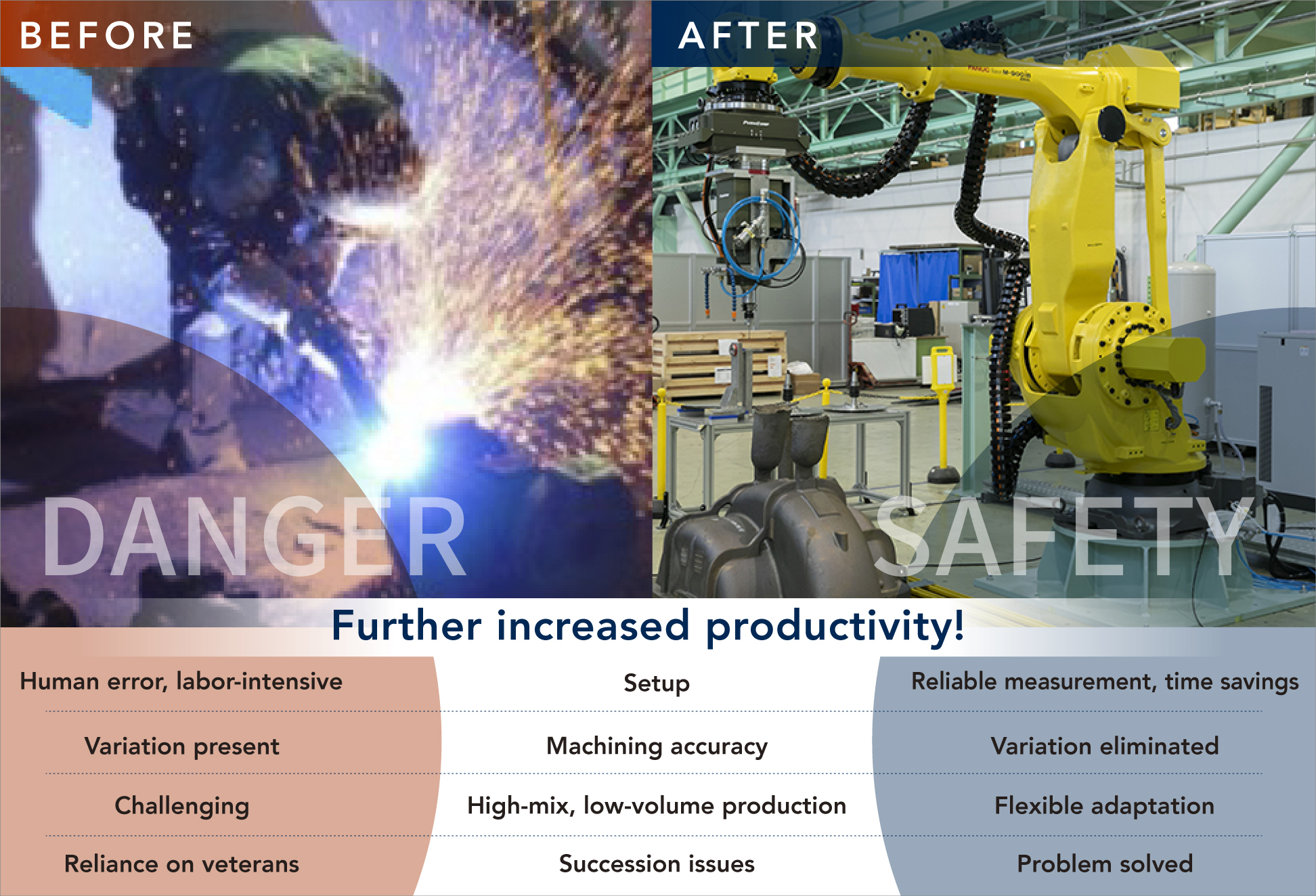

What are expected outcomes after implementation?

The implementation of this robotic machining system, enabled by a touch probe and active compliance force controller device, is expected to deliver the following outcomes:

The greatest expected outcome is a significant improvement in safety!!

In addition to safety, various productivity improvements can be expected.

- Setup: Reliable, sensor-based measurement eliminates human error and reduces setup time

- Machining accuracy: Eliminates human variation to achieve stable machining accuracy

- Flexibility: Automated workpiece origin setting, tool changing, and machining enable flexible adaptation to high-mix, low-volume production

- Skill transfer: Solves the problem of reliance on veterans for skill transfer

[Future Prospects] Weld bead finishing and precision grinding of large components

The combination of the RC-K3X and PushCorp holds even greater potential for future applications.

For example,

- Weld bead finishing: Measure protrusions with the RC-K3X and process them at optimal grinding pressure

- Aircraft and aerospace components: Handle super-large components not suitable for machining

- Proven applications in fine grinding and scale removal of various materials

Q. Tell us about your vision for future development.

Aichi Sangyo Co., Ltd. Leader Takemoto

“In our current application, we have not yet fully utilized the RC-K3X's repeatability of 1μm (2σ). We want to build a system that truly leverages this capability.”

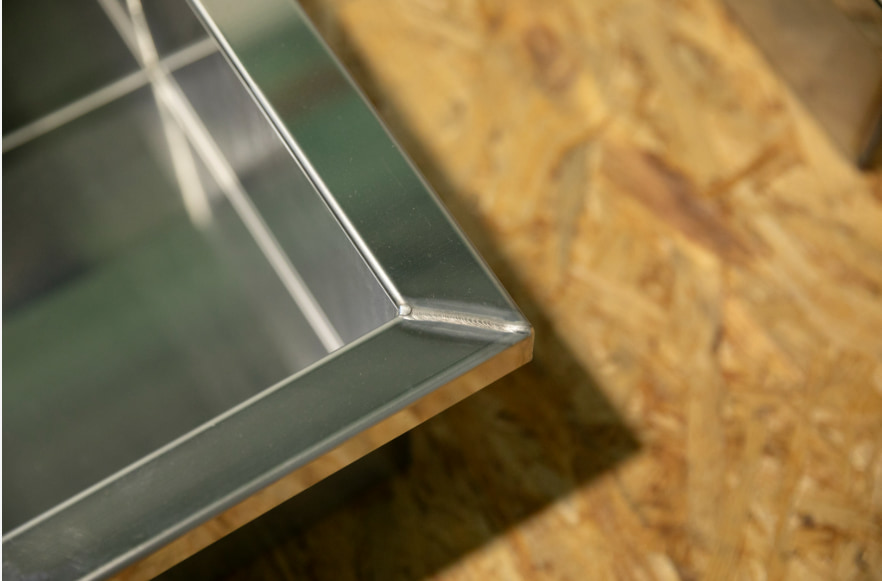

“One concept we are exploring is post-weld finishing.” When welding with a filler metal for joining, a fish cake-shaped protrusion known as “weld bead” is formed. The PushCorp device is used to grind this down to achieve a mirror finish.

However, we adjusted the pressing force for safety so as not to damage anything other than the protrusion.

We believe that by measuring the bead height and width with the RC-K3X before grinding, we can optimize the pressing force, thereby improving production efficiency and machining accuracy. Through this system development, we see significant potential for the combination of PushCorp and the RC-K3X touch probe in various other applications, particularly in robotic cutting, machining, and grinding systems where accuracy has been a barrier to automation. Please consult us for such projects.

System Integrator with deep field expertise provides total automation support

This system was built by Aichi Sangyo, an import trading company with in-house engineering capabilities.

By leveraging its extensive expertise in robot control using PushCorp's active compliance force controller device, the company provides comprehensive support for:

- Building robotic systems

- Creating and customizing programs

- Operational training and startup assistance for on-site personnel

The company has a solid reputation for "delivering the optimal solution tailored to the site once entrusted with a task."

Interview cooperation: Aichi Sangyo Co., Ltd.

Product introduced by Aichi Sangyo Co., Ltd.: PushCorp's Active Compliance Force Controller Device

The products featured in this case study

Wireless High-Precision Touch Probe

The RC-K3X series is a Japan-made wireless 3D touch-probe sensor that is mounted inside CNC machine tools such as machining centers to measure the dimensions of machined workpieces.

Using wireless communication, the receiver transmits the probe's measurement signals to the machine.

![[RC-K3X Series]](https://metrol-sensor.com/wp-content/uploads/2025/10/RC-K3X_bg-6-800x530-1-800x530.png)