Features

IP67 protective structure, outstanding durability against coolant

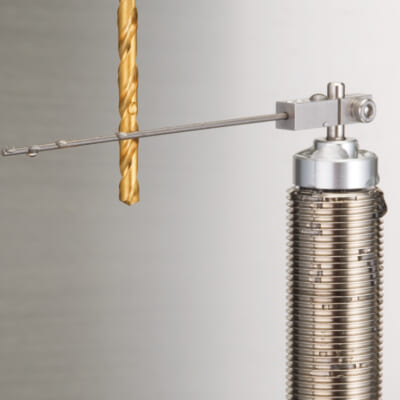

The world’s first air-driven system!

Without the use of a control motor, this sensor demonstrates outstanding durability even in adverse environments inside the machine tool where it is exposed to chips and coolant.

Users will achieve significant reduction in maintenance costs caused by breakdowns.

Achieves affordable tool breakage/damage detection.

Eliminates the need for expensive control motors and control units.

The mounting diameter is M22, and it is also interchangeable with conventional parts.

High reliability + Low cost: Fewer false detection achieved by touch sensor method

Since the detection is made by the needle’s direct contact with the tool, coolant splatter or mist is less likely to interfere when comparing with expensive non-contact sensors (e.g., laser sensors), thus ensuring high reliability.

![Drill Bit Breakage Detection Sensor [DFM Series]](https://metrol-sensor.com/wp-content/uploads/2021/01/img_products_tool_setter_dfm.png)

![工具折損検出センサ[DFMシリーズ]の回路図](https://metrol-sensor.com/wp-content/uploads/2021/03/DFM3-Names-of-componests-and-internal-structure-3.png)