Features

1μm repeatability, durability of 3 million cycles

Operates at the moment the touch-probe contacts the workpiece, enabling highly precise position detection.

No directional variation

By limiting the detection direction to three, differences in sensitivity (directional characteristics) are minimized, and detection differences in the ±X direction are minimized, enabling highly precise detection.

Built-in I/F unit

An I/F unit is equipped as standard to prevent damage to the touch-probe due to in-machine shocks and vibrations or sudden overcurrent from external sources. Also, the I/F unit can be attached externally as an option.

High water and dust resistance with IP67 protection rating

Applicable for use in adverse environments with splashing water, oil, coolant, and chips.

Resistant to vibration due to pre-travel (PT)*.

(*Pre-travel: the amount of movement from the time the touch-probe contacts the work to the time the output switches)

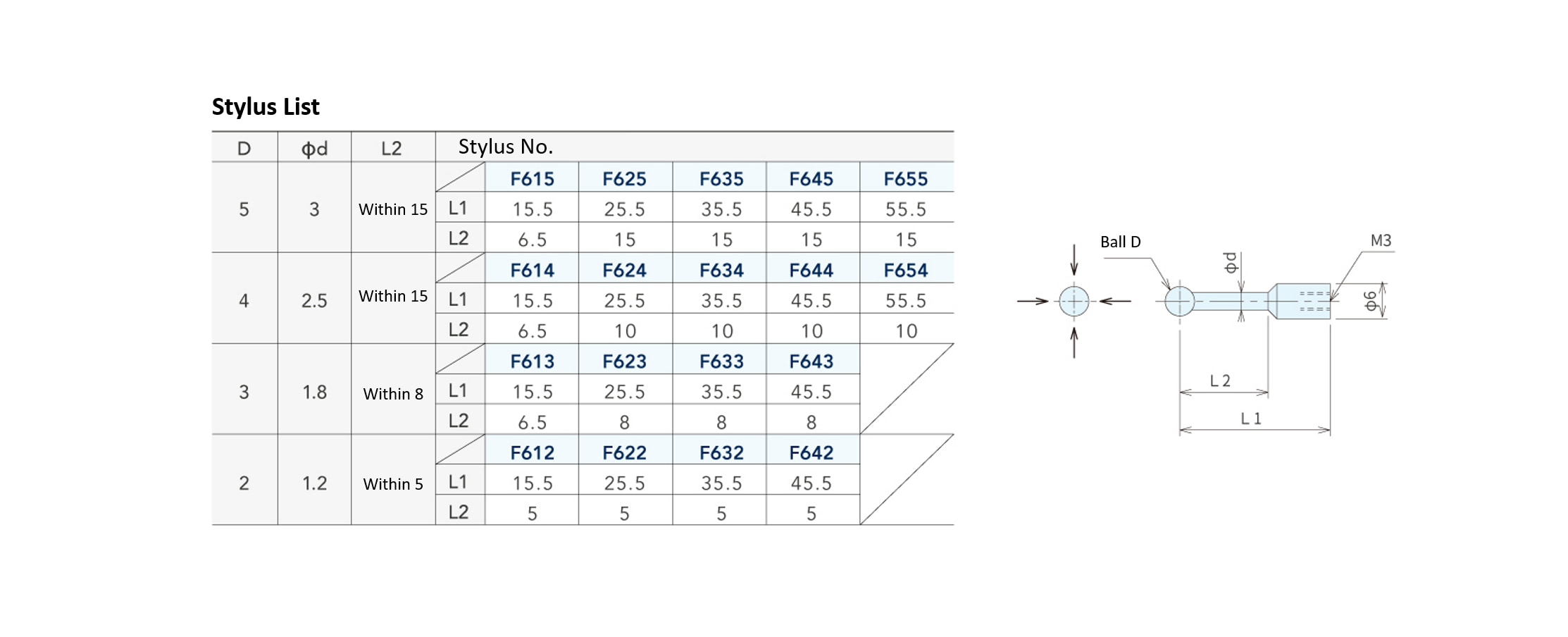

Wide variety of optional items

Stylus, mounting method, cord length, and other options can be selected.

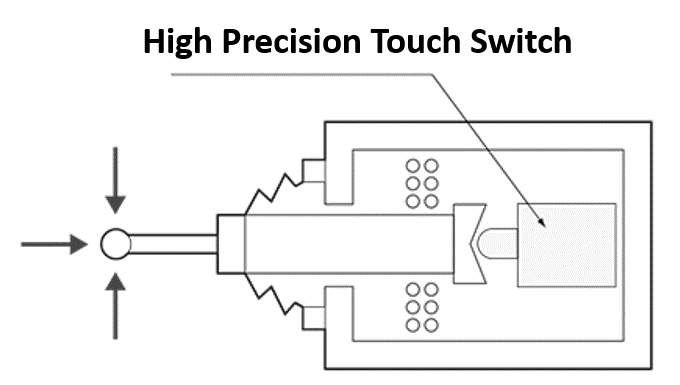

Principle Structure

By placing the touch-probe on the stylus tip against the workpiece or table, a high-precision ON/OFF signal is output, which can be input to NC/PC equipment.

Built-in high-precision, high-durability touch switch is activated by stylus movement.

- Because of the pre-travel, false signals and chattering due to vibration and shock do not occur.

- Touch-probes are made of low-electrical resistance material for long life.

- There is no change in contact force based on the direction of detection.

- It supports both NC and NO (Open and Closed) contact structures.

- Pre-travel and homing errors do not affect repeatability.

![Wired Touch-Probe for CNC Lathes and Special Purpose Machines [K2A Series]](https://metrol-sensor.com/wp-content/uploads/2021/02/img_products_touch_probe_k2a.png)

![CNC旋盤・専用機用 有線式タッチプローブ[K2Aシリーズ]の回路図](https://metrol-sensor.com/wp-content/uploads/2021/03/K2A-circuit-diagram.png)