How to achieve space-saving positioning in high vacuum environments with low outgassing

Table of Contents

What issues occur with vacuum environments?

Various problems are caused by outgassing

"Outgassing" is one of the most important issues with manufacturing processes in vacuum environments.

It occurs with various components such as jigs, parts, adhesives, and cords when used in a vacuum environment.

The outgas from material adheres to the inner wall of the vacuum chamber and workpieces leading to problems such as:

- Yield reduction due to defective products

- Quality problems

- Increased inspection costs

Accordingly, it is important to select and adopt "low outgassing" jigs, parts and materials for use in vacuum environments.

A design for a small space is required

Because Semiconductor manufacturing equipment and vacuum chambers have only a small space inside, designer needs to make drawing limited space and use low-outgassing materials.

Therefore, "How to design equipment without generating outgassing in a vacuum environments with limited space?" could be one of the major issue in manufacturing in high-vacuum environments.

What are the features of High-Vacuum-Resistance Switches?

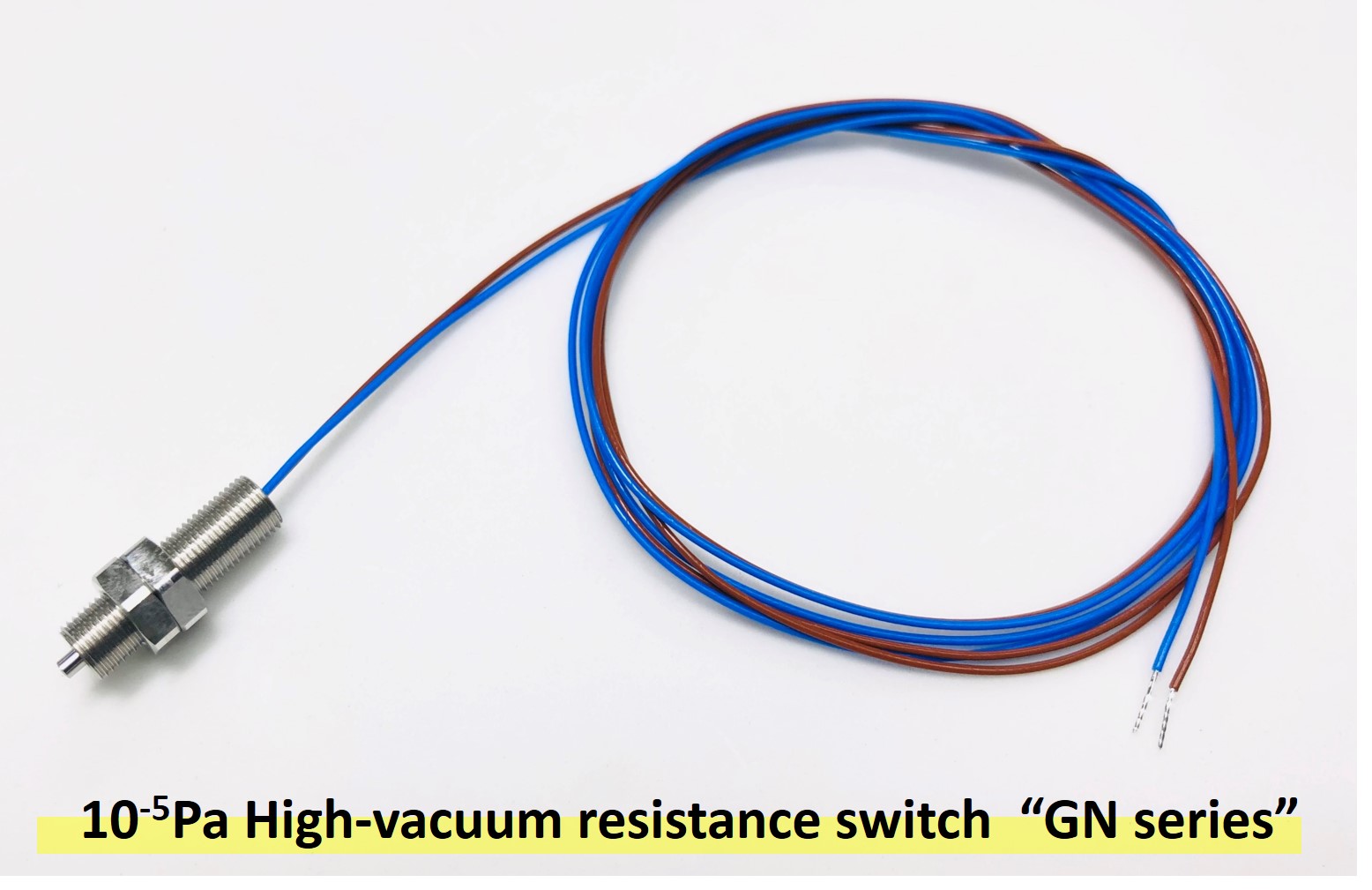

Introduction to 3 features of GN series High-Vacuum-Resistance Switches:

This product is a "touch switch" that outputs an ON/OFF signal by contacting a jig or workpiece.

These are commonly used with all kinds of equipment and robots for positioning and locating home positions.

The following are three features of vacuum compatible GN series units.

Feature 1: Low outgassing material is used for the body of the switch

Feature 2: Ultra-compact size enables space savings

Feature 3: Assembly is performed in a cleanroom to prevent contaminationCatalog

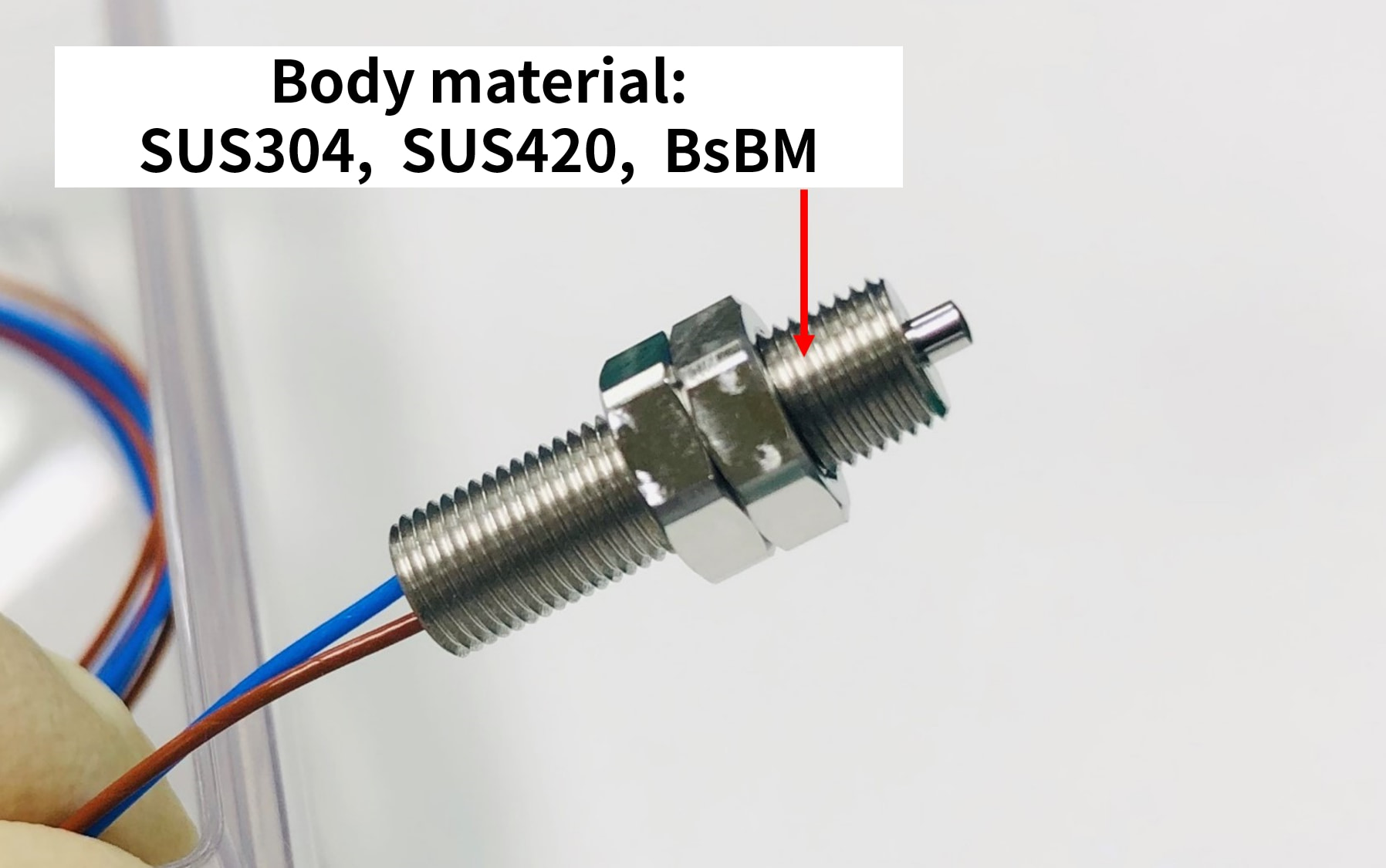

Feature 1: Low outgassing material is used for the body of the switch

High-Vacuum-Resistance Switches

are made of materials that minimize the occurrence of outgassing, a common cause of contamination, with almost no outgas generated even in high vacuum class 10-5 Pa environments.

The materials used for the switch body are as follows.

[Body material]

・SUS304

・SUS420

・BsBM

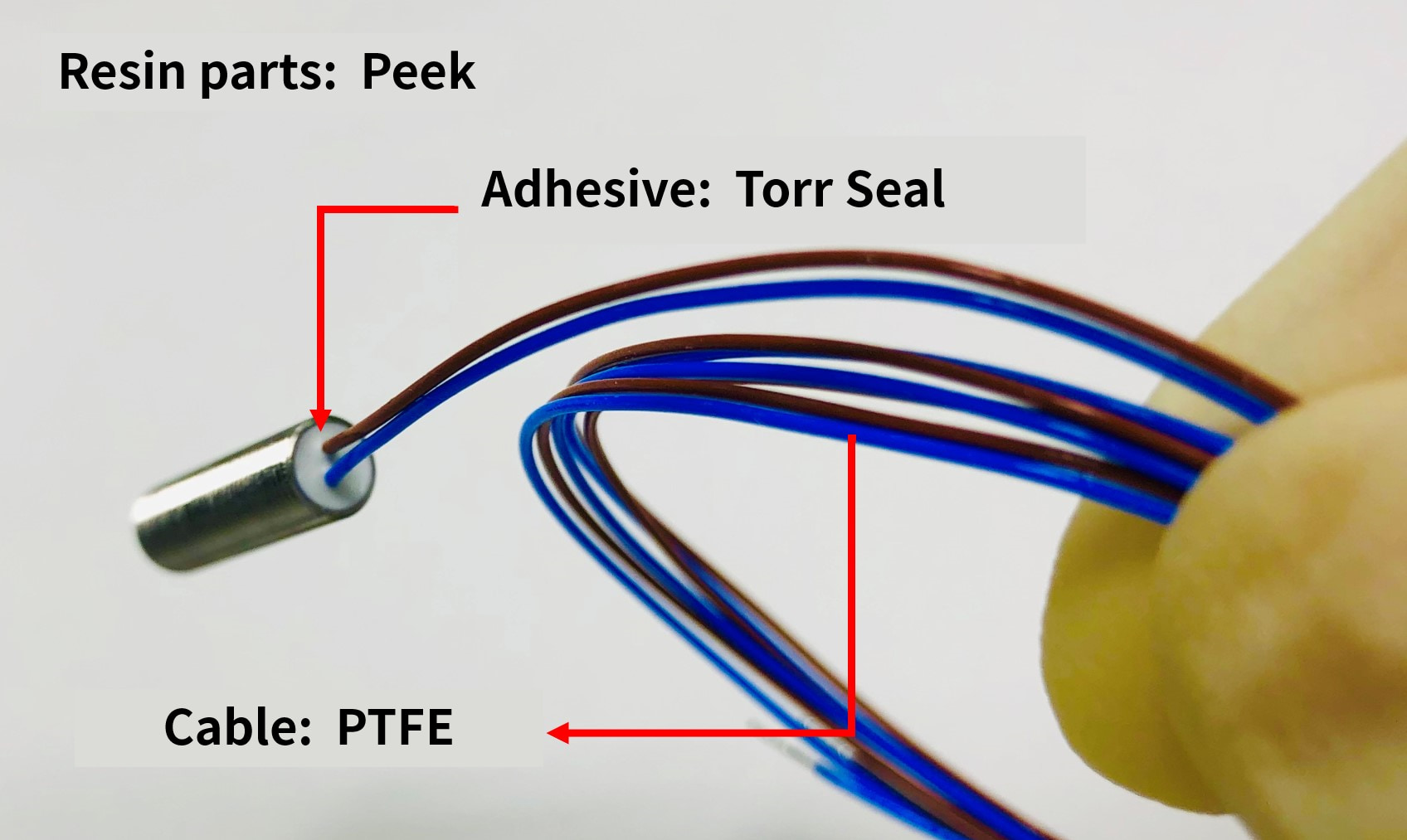

[Resin parts]

“PEEK" is used for the resin parts inside the vacuum compatible switch.

This is a low outgassing material with very low volatile organic compound and metal ion content, enabling use in vacuum environments without worrying about contamination.

[Body cable]

Using "PTFE" material.

[Adhesive: Torr Seal]

Using low outgassing adhesive “Torr Seal”.

[Other constituent substances]

No grease, lubricants or oils are used for High-Vacuum-Resistance Switches.

Catalog

Feature 2: Ultra-compact size enables space savings

The GN series of High-Vacuum-Resistance Switches are ultra-compact positioning switches that can be easily installed in tight spaces.

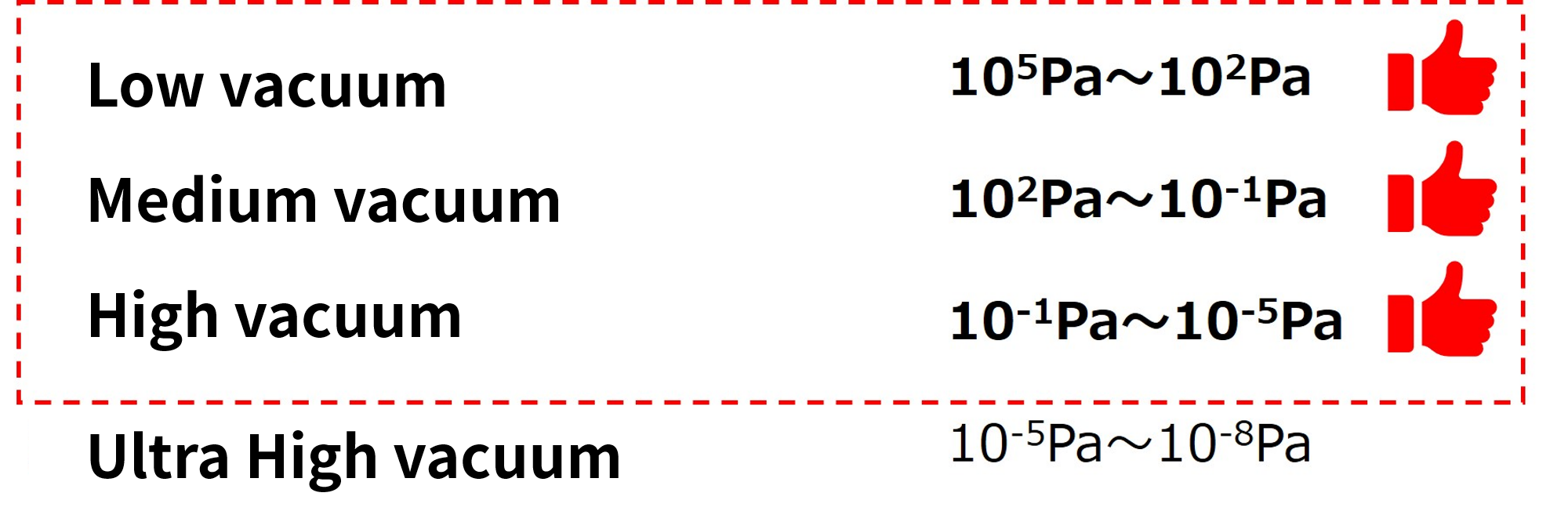

Feature 3: Low outgassing even in high vacuum class 10-5 Pa environments

The switch body is made of a low outgassing material that can be used in high vacuum environments (10-1 Pa to 10-5 Pa).

Some common high vacuum processes used in the industry include vacuum deposition, sputtering and thin film processing equipment.

※ordinary environment ~ high vacuum environment: HV: high vacuum (10-1Pa~10-5Pa)

▲High-Vacuum-Resistance Switch GN Series Usable Pressure Range

Feature 4: Assembled in a cleanroom to prevent contamination

High-Vacuum-Resistance Switches are assembled under the following conditions to prevent contamination.

・ Parts for assembly are cleaned prior to use

・ Assembly is performed in a cleanroom

・ Latex gloves (powder free) are use when assemblingCatalog

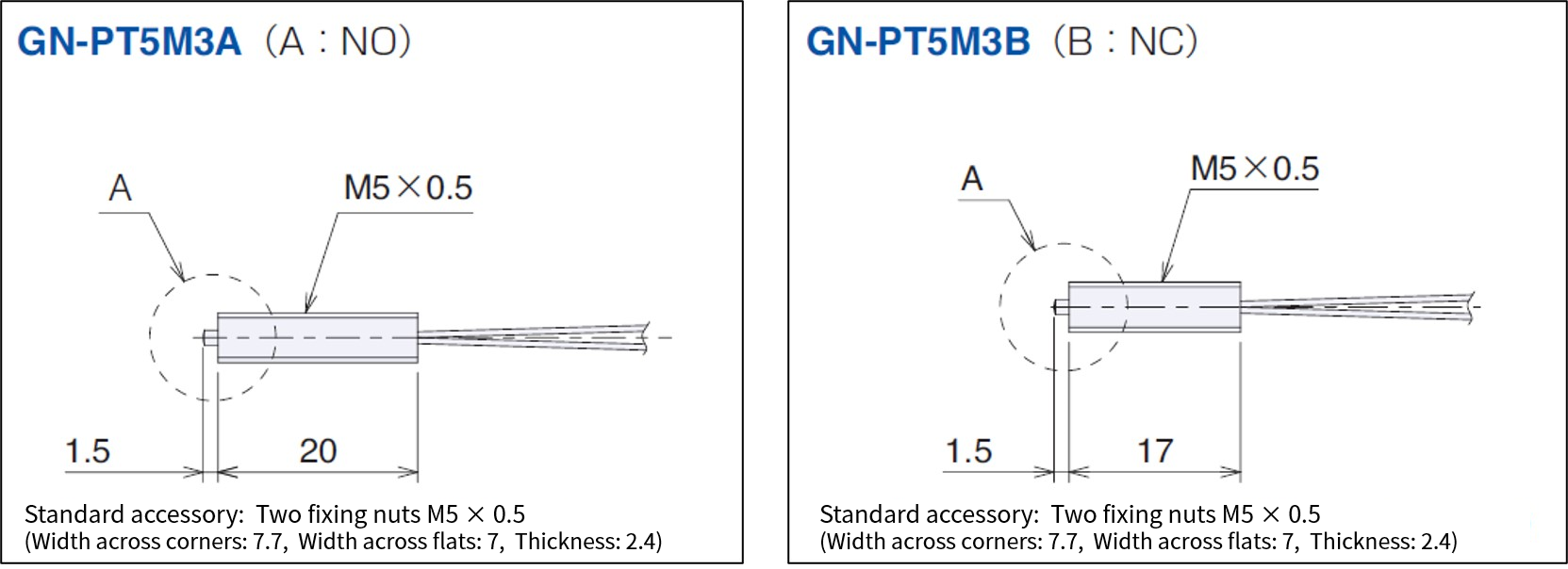

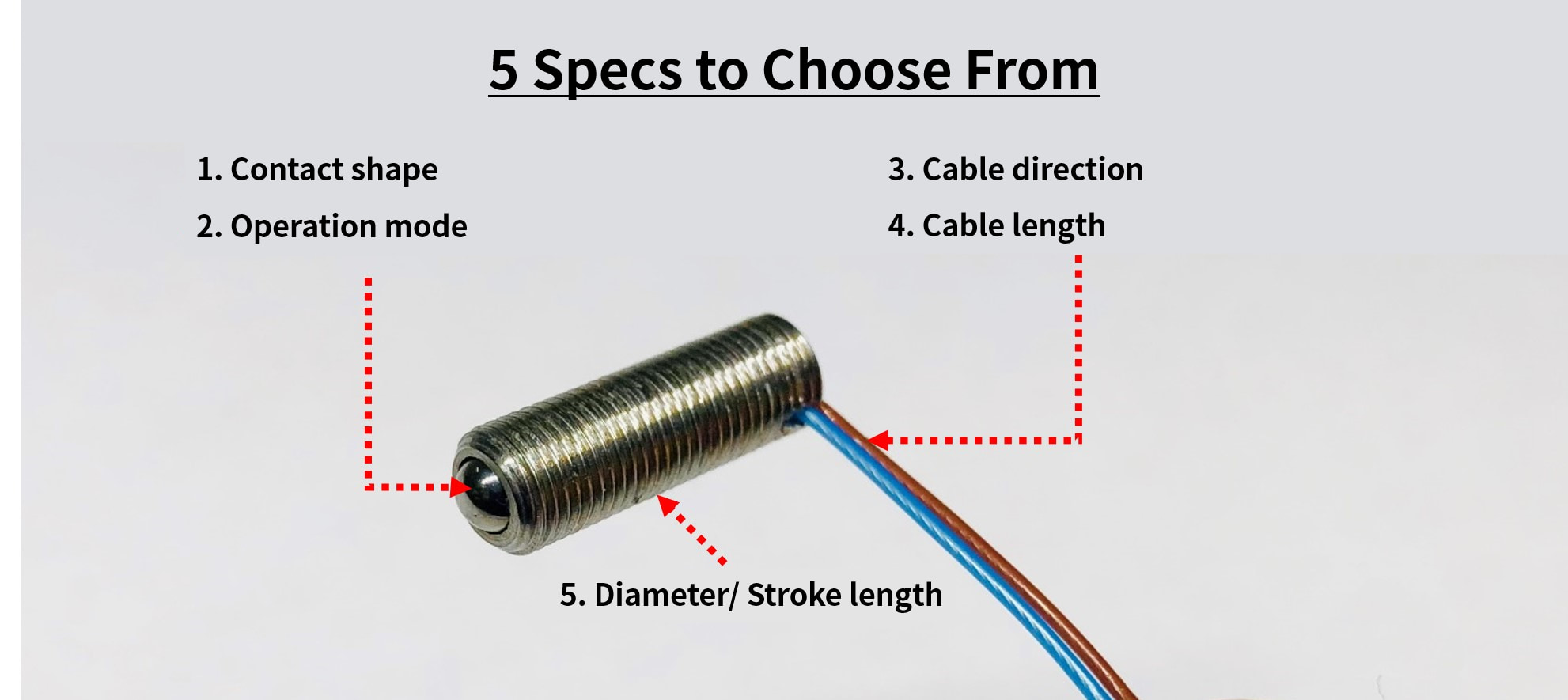

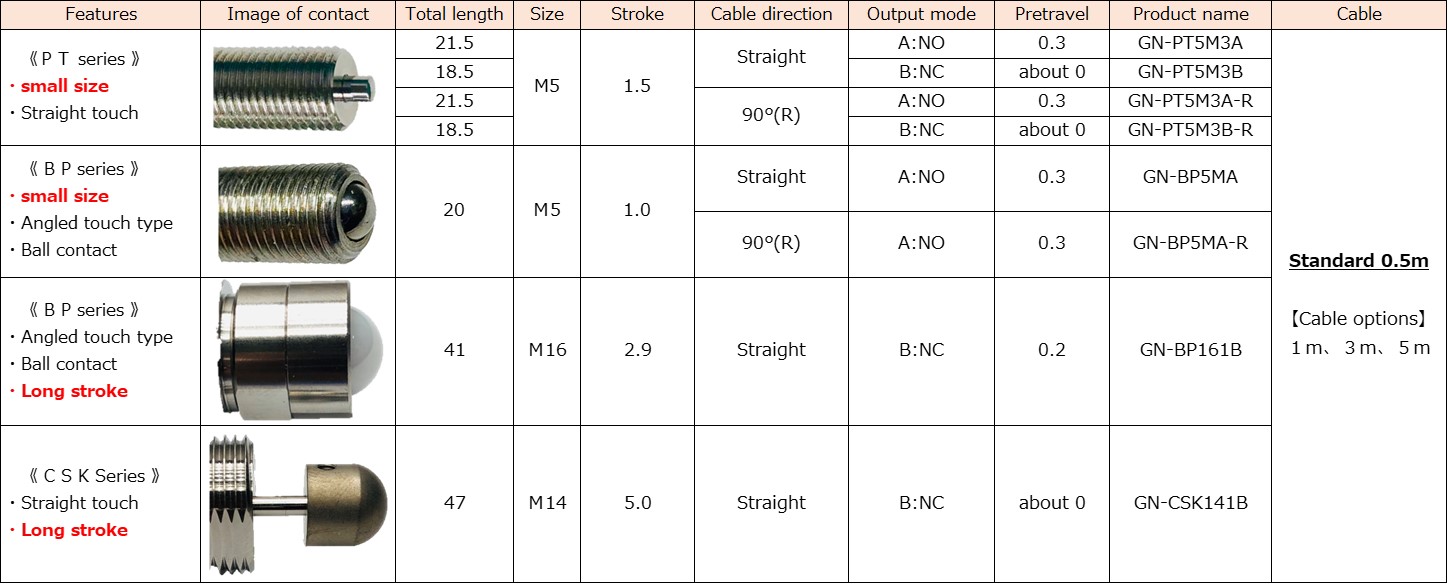

Choosing Between Types of High-Vacuum-Resistance Switches

The following five specification options are available to choose from.

・ Contact shape

・ Cable direction

・ Cable length

・ Operation mode: Normally open (NO) or Normally closed (NC)

・ Diameter/ Stroke length

Specification 1: Contact shape

The switch outputs a signal when the contact surface is touched.

The contact shape should be selected according to the angle at which the object is to be contacted.

The following two types of contact shapes are available for High-Vacuum-Resistance Switches.

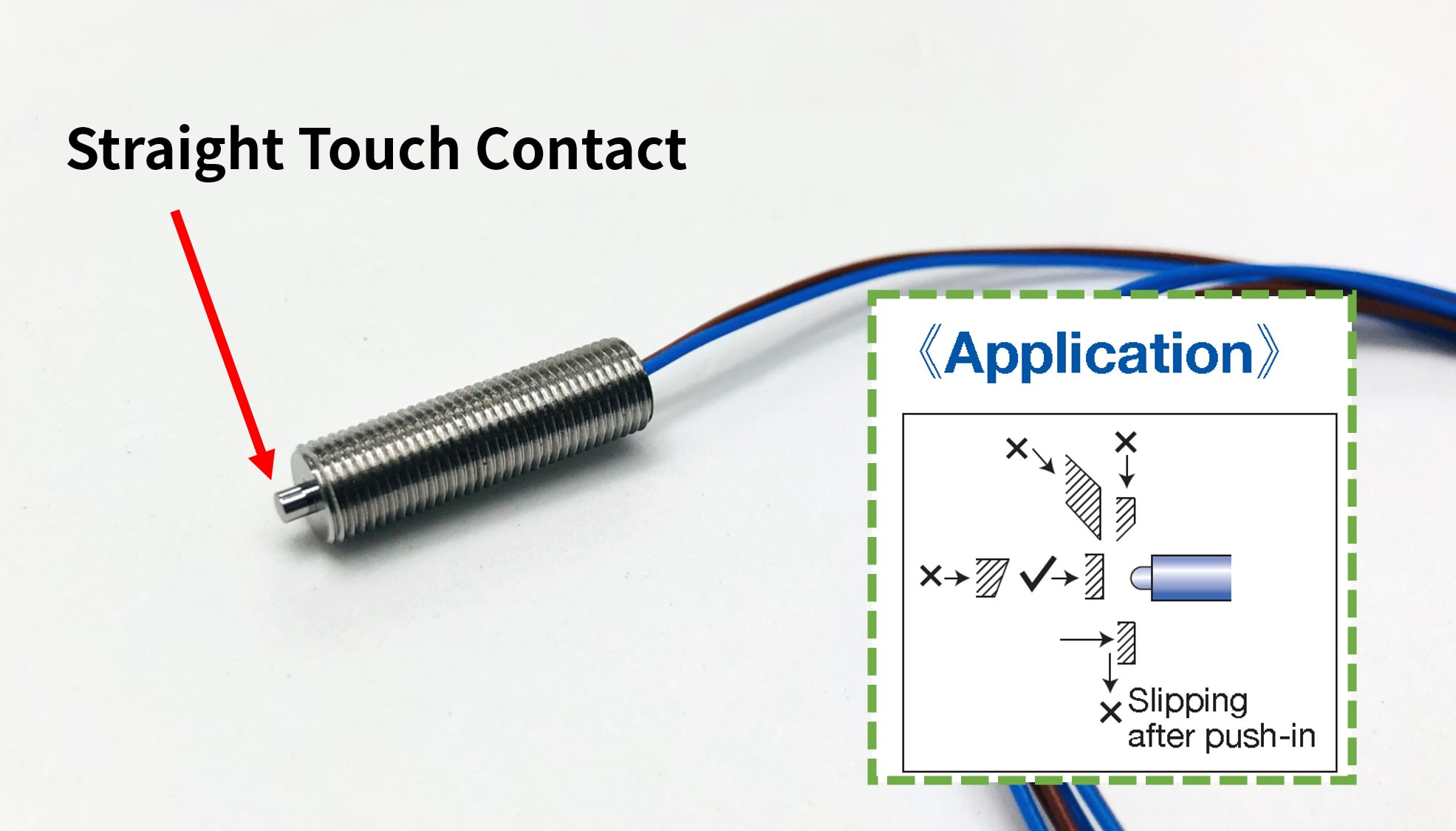

(1) Straight contact

(2) Angled contact

(1) When the contact is touched from the front: "Straight contact type"(PT series)

*Precautionary note

Straight contact types cannot be used if contacting at an angle as the contact point or internals may be damaged.

Please arrange always in such a way to ensure contact will occur from a straight-on direction.

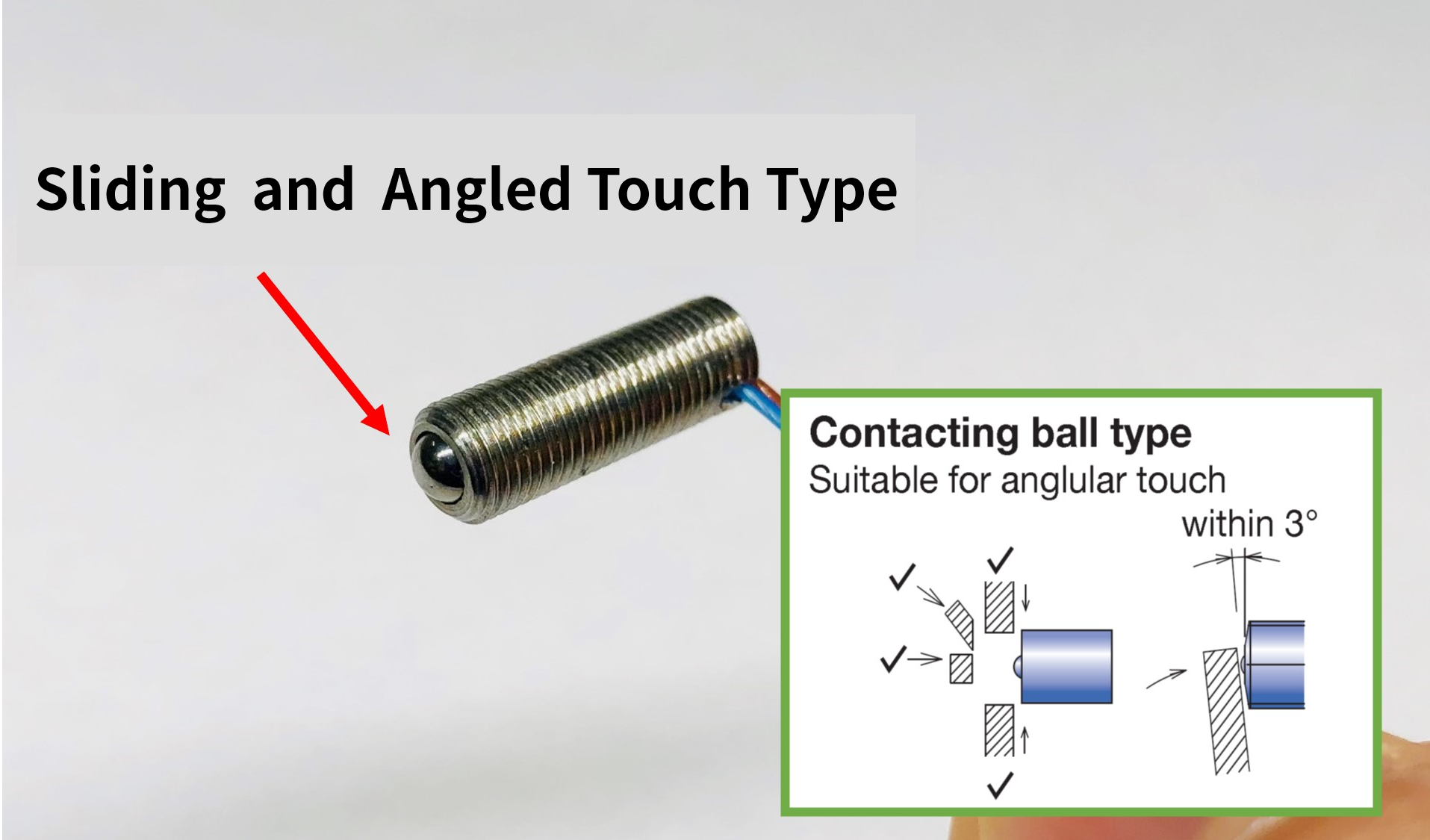

(2) When the contact is touched at an angle: “Angled contact type” (Ball contact BP series)

・Workpieces with a curved contact surface

・ Large LCD panels or circuit board workpieces that may be warped

Select an angled contact (BP series) switch with a ball contact in the above cases.

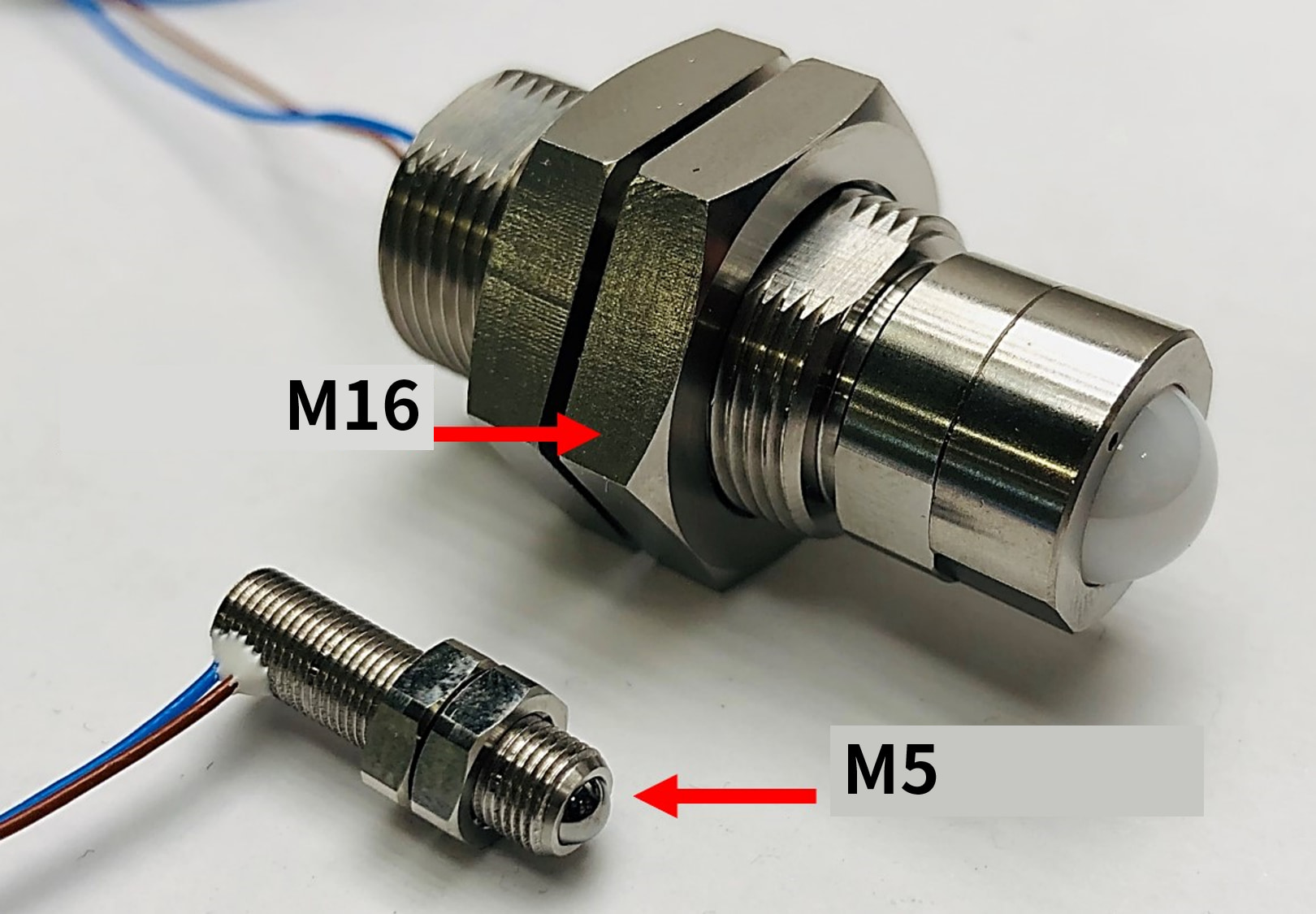

Ball contact type of High-Vacuum-Resistance Switches come in 2 types of diameters and stroke lengths.

・Type M5 stroke length:0.8mm

・Type M16 storke length:2.9mm

Catalog

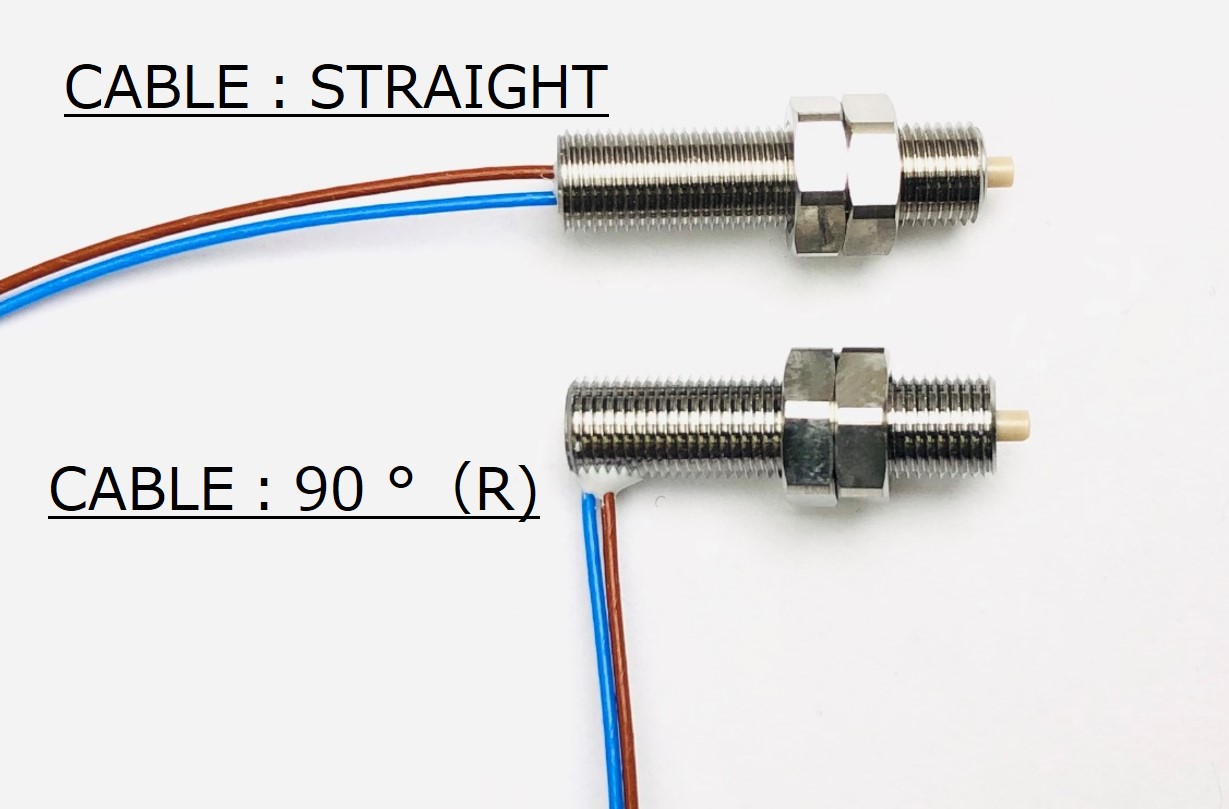

Specification 2: Cable direction

Select from the following 2 types of switch cable direction.

(1) Straight

(2) 90°(R)

Select the direction according to how you want to manage the cable within a vacuum device or chamber where space is limited.

Specification 3: Cable length

The standard cable length for High-Vacuum-Resistance Switch is 0.5 m.

The length can be selected from the following three types of options.

《Options of the cable length》

・1m

・3m

・5m

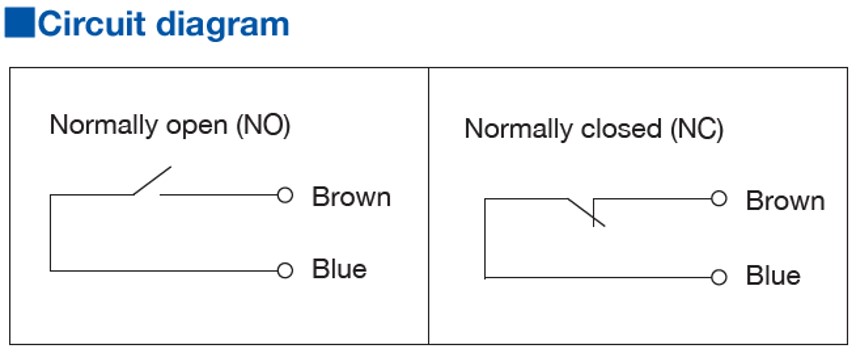

Specification 4: Operation mode

There are 2 operation modes, normally open and normally closed.

The signal operating point is different between normally open and normally closed modes.

・ Normally open (NO):

A signal is output when the switch makes contact with a contact surface and is depressed 0.2 to 0.3 mm.

・ Normally closed (NC):

0 pre-travel (the distance traveled before signal is switched). Signal is output when contact is made with the target.

Summary of the specifications:

・ Contact shape

・ Cable direction

・ Cable length

・ Operation mode: Normally open (NO) or Normally closed (NC)

・ DiameterCatalog

《High-Vacuum-Resistance Switch GN Series Specifications Table 》

*1: Overall length = From the contact tip to the end of the body (doesn’t include cord length)

*2: Unit of length:mm

FAQ & Points to Remember

Heat resistance temperature (upper and lower limits)

The upper limit for heat resistance of High-Vacuum-Resistance Switches is 120°C and the lower limit is 0°C.

When baking for outgassing, it can be used at up to 120°C for up to about 2 hours without any problems.

Operation speed and chattering

Avoid using low operating speeds of 10mm/min or less as there is a risk of chattering.

Contact life

Can be used for 3 million ON⇔OFF transitions.

Installation tightening torque of nuts and screws

The tightening torque of nuts and screws when installing the switch should be 1N/m.

Success Stories and Applications

This section introduces success stories of High-Vacuum-Resistance Switches by industry, application and workpiece.

Industries:

・ Semiconductor

・ LCD panel

・ OLED

・ Aerospace

Case studies/applications:

The following positioning applications within vacuum environments are common.

・ Workpiece origin finding

・ Workpiece seating

・ Jig positioning

Detectable workpieces:

・Substrates, glass, metal, plastic

Actual implementation examples:

・ Stage positioning within vacuum chambers

・ Workpiece positioning within vacuum deposition devices

・ Sputtering equipment

・ Positioning within thin film manufacturing equipment

・ Semiconductor wafer positioning

・ Vacuum compatible positioning stages

・ Verifying mask seating with substrate holdersCatalog

Improvement Example with High-Vacuum-Resistance Switches

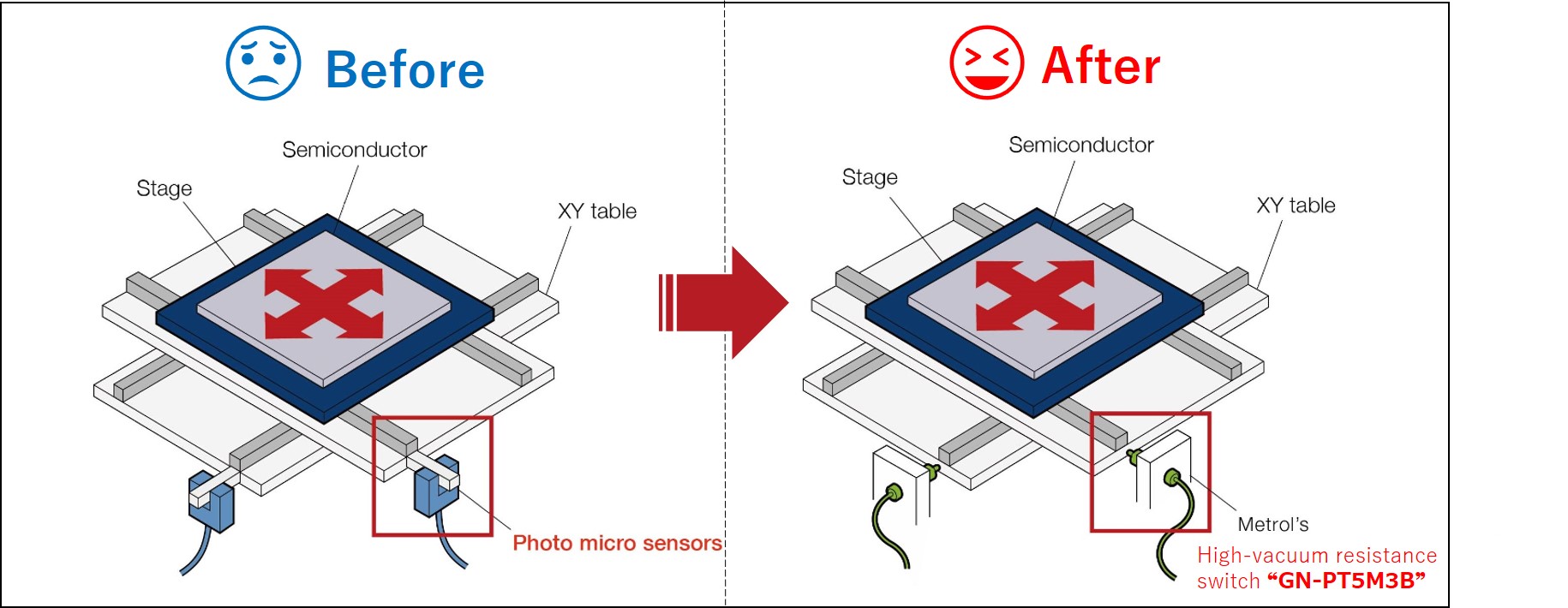

Adoption example 1: Semiconductor XY table positioning

Problem point

- XY axis shifts by a few microns due to self-heating.

- Photo micro sensors are not capable of accurate origin finding.

After improvement

- Precision detection of table position is possible with a contact type touch switch.

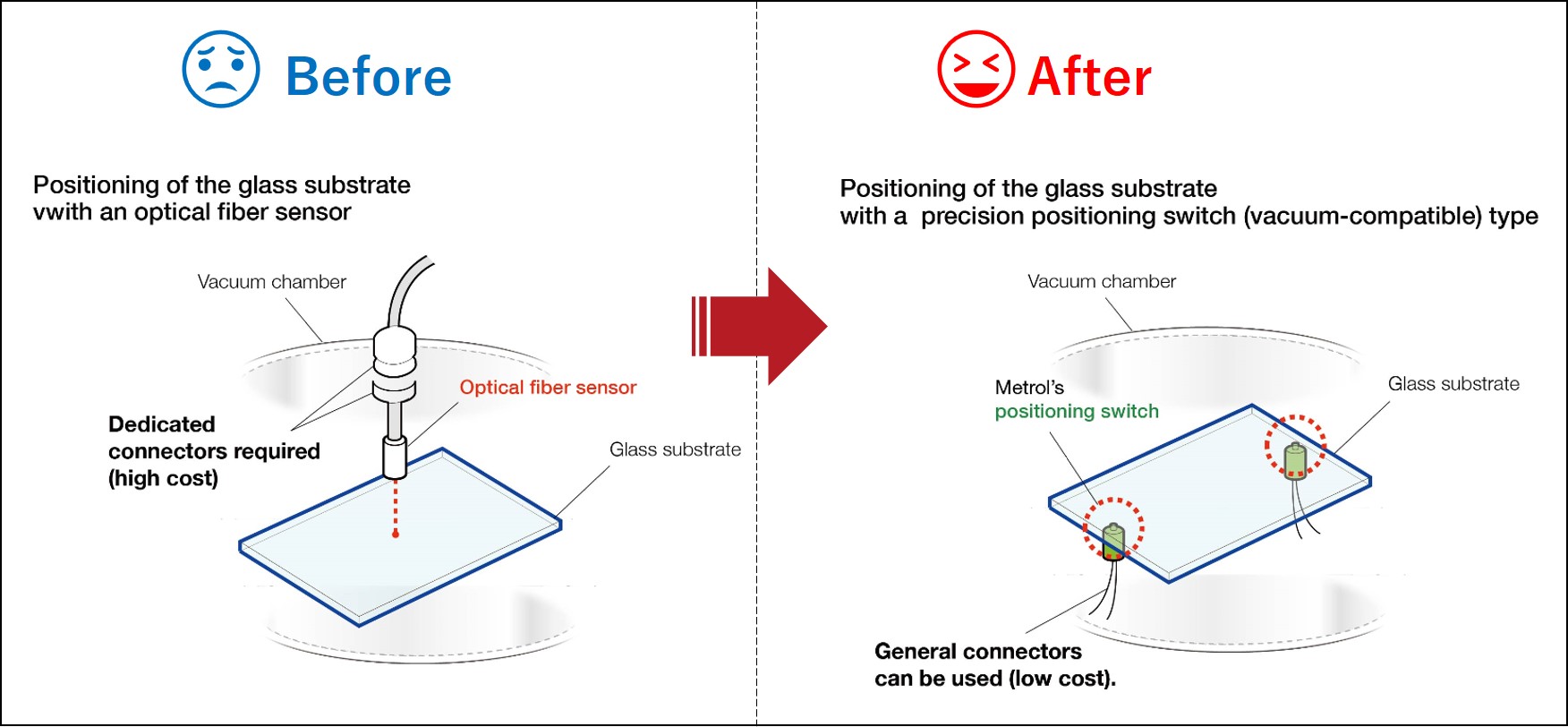

Adoption example 2: Glass substrate seating confirmation

Problem point

- Special vacuum connectors are expensive at over $2,000 USD.

- Installing of a view port is required.

* ”Transparent vacuum fiber sensors” or “displacement sensors” from other manufacturers are available as replacement products.

However, compare to the High-Vacuum-Resistance Switch, which is typically around $300 ~ $500, the price range of fiber sensor is much higher at $2000 ~ $5000 or more per unit and amplifier.

After improvement:

- Special, expensive vacuum connectors are not needed.

- Costs can be saved by not requiring a view port.

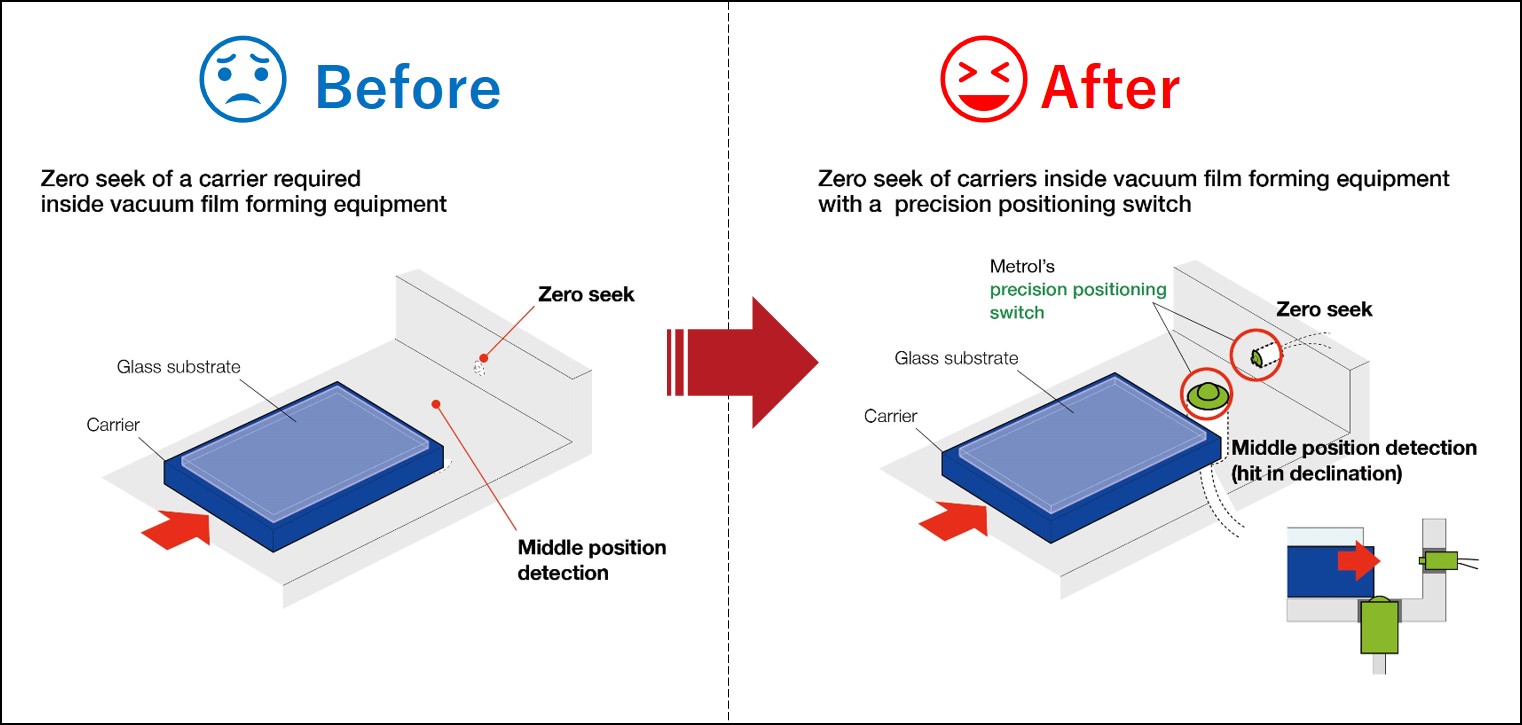

Adoption example 3: Carrier origin finding

Problem point

- I want to find the origin of a sliding carrier using 2 points with the bottom and side surfaces.

After improvement:

- Embedding a ball contact type touch switch into the jig enabled a seating bottom surface positioning system to be designed.

- High precision origin finding of side surface was designed using a straight touch type switch.

Contact and Product Information

《Contact》

Our engineers will respond to any questions regarding product usage methods or requests to customize products.

We can provide our best support if details about application, usage environment and what kind of workpieces will be detected can be provided.

Use our contact form below to contact us.

More information about High-Vacuum-Resistance Swiches:

Please fill the following form to download it.Catalog

《Production site》

Click here to go to the site of GN series