Resolved a false detection of the photo sensor under high-vacuum environment

Semiconductor industry

A manufacturer of semiconductor manufacturing equipment that designs vacuum deposition devices to manufacture semiconductors for photovoltaic panels.

A representative of substrate sensing parts design department inquired us about "positioning" of glass substrates under vacuum environment.

Table of Contents

Client’s Issues

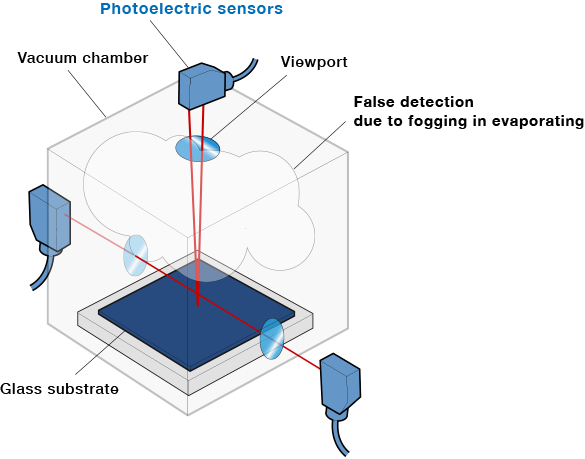

The "photoelectric sensor" has been used to detect a presence of a glass substrate within the vacuum chamber, however, there was some trouble in many false detection due to fogging of the view port in evaporating.

Furthermore, there was another problem; the view port itself is expensively machined.

The client consulted major sensor manufacturers and tried a high-performance photo sensor, however, using it cannot prevent false detections.

A visit of our booth in the "Vacuum Exhibition" for mold technologies encouraged the client to know our switches and to contact us.

The main focus of the issues

Positioning the glass substrate under vacuum environment.

Fogging of a view port in evaporating causes a false detection in the photo sensor.

The view port is expensively machined.

Metrol’s suggestions

Because the conventional "photoelectric sensor" detects workpieces with a reflection by emitted lights, they are subject to external conditions such as fogging, water drops and diffused reflections, etc., which consistently causes false detections.

Most engineers assume that "A sensor is useless under vacuum environment".

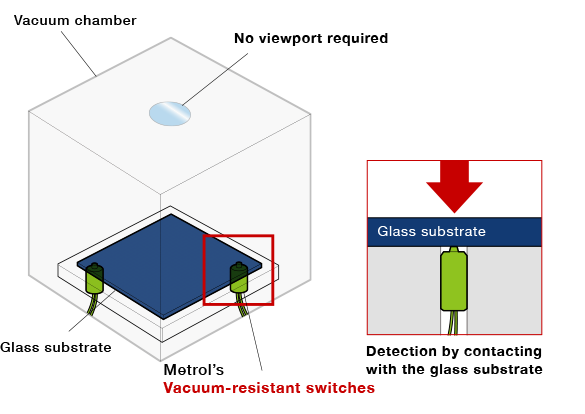

Metrol's "high vacuum class-compatible switch" is a mechanical precision positioning switch manufactured only with low outgas-compatible parts without any electric substrate.

The switch is compatible with high vacuum class up to 10^-5 Pa and capable of securely detecting the glass substrate even under high vacuum environment.

We customize the switch contact force to 0.5 N or less and the tip material to special resin respectively, so there is no risk of scratching the sensitive glass substrate.

Improvements

Realization of positioning the wafer under the 10^-5 Pa high vacuum environment.

No false detection by directly contacting the wafer.

The need for the view port is eliminated, and the machining cost is reduced significantly.

Comment from Metrol representative

Because the signal points of the photo sensors such as "photoelectric sensor" and "fiber sensor" are invisible, adjusting the installation has taken more than two days.

Because the signal points of Metrol's contact-type "precision positioning switch" are visible, the installation positions can be specified on the CAD when designed.

In the semiconductor industry, we have many past adoption experiences also about positioning within vacuum devices such as "sputtering device", "organic EL evaporating device", "etcher", and "wafer carriers", etc.

If you have any trouble in positioning or detection of the presence under vacuum environment, please feel free to contact Metrol.

We look forward to hearing from you preparing our samples for the evaluation.

For further information about the products used in this application

High-vacuum resistance Switches

Resolved a false detection of the photo sensor under vacuum environment!