Features

Install measurement functions on machine tools

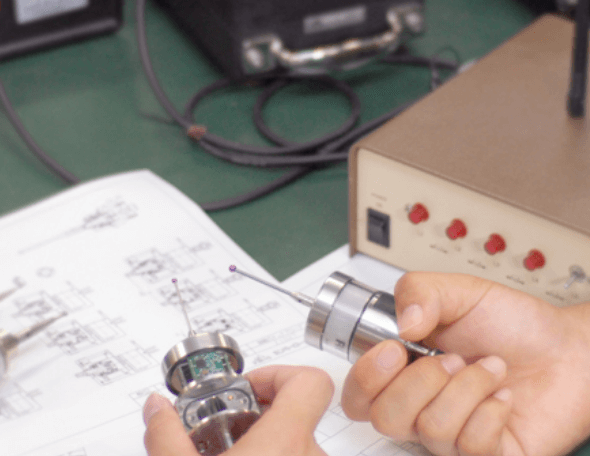

It operates at the moment the measuring element contacts the workpiece, enabling highly accurate position detection with a repeatability of 1μm.

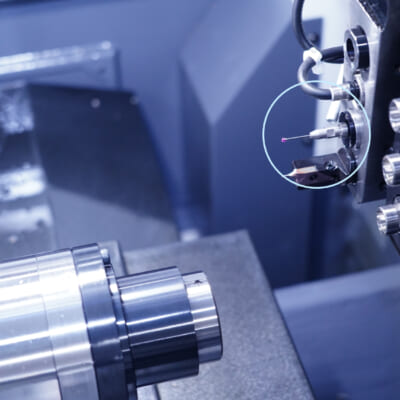

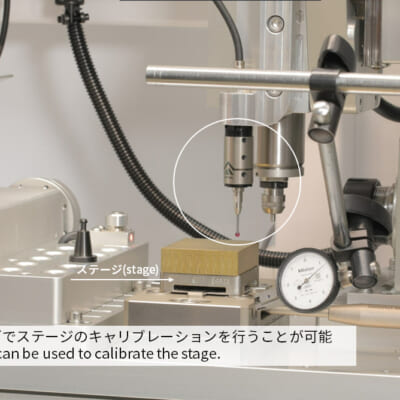

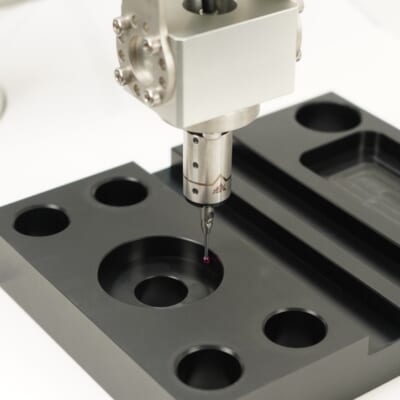

When mounted on high-precision processing machines such as NC grinders and CNC automatic lathes, it acts like a simple 3D measuring machine.

It eliminates manual variation in workpiece measurement and reduces setups such as moving and setting workpieces for inspection, thereby realizing cost reductions.

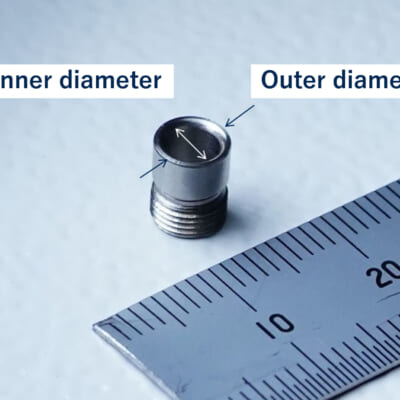

Smallest diameter for machine tools

The smallest diameter is φ17.8mm to φ19.05mm, and the main unit is designed to fit tightly into the milling holder of a lathe or other machines.

It can be mounted on a grinding machine or CNC lathe with limited space without interfering with other tools.

*In the picture, the main unit is clamped and the side is fixed with an set screw for installation.

Excellent resistance to water, coolant, and dust with IP68 protection rating

Spec’d with IP68 protection rating, designed for use in adverse environments and has passed high-pressure coolant durability tests inside machine tools for more than 300 hours.

High repeatability even when used in machine tools with splashing coolant and chips.

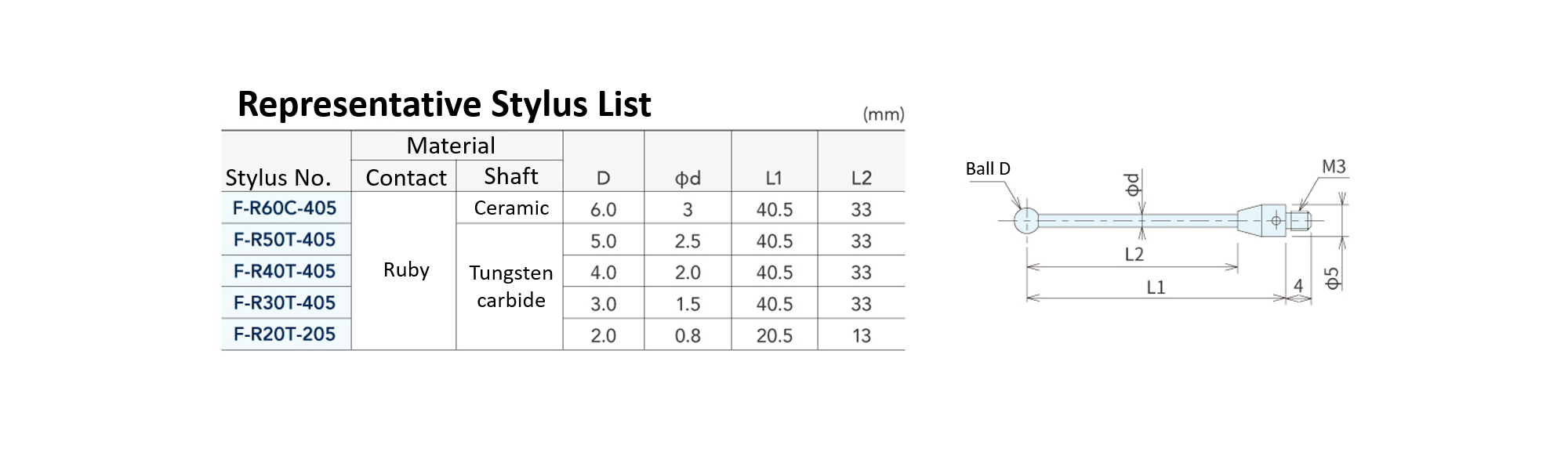

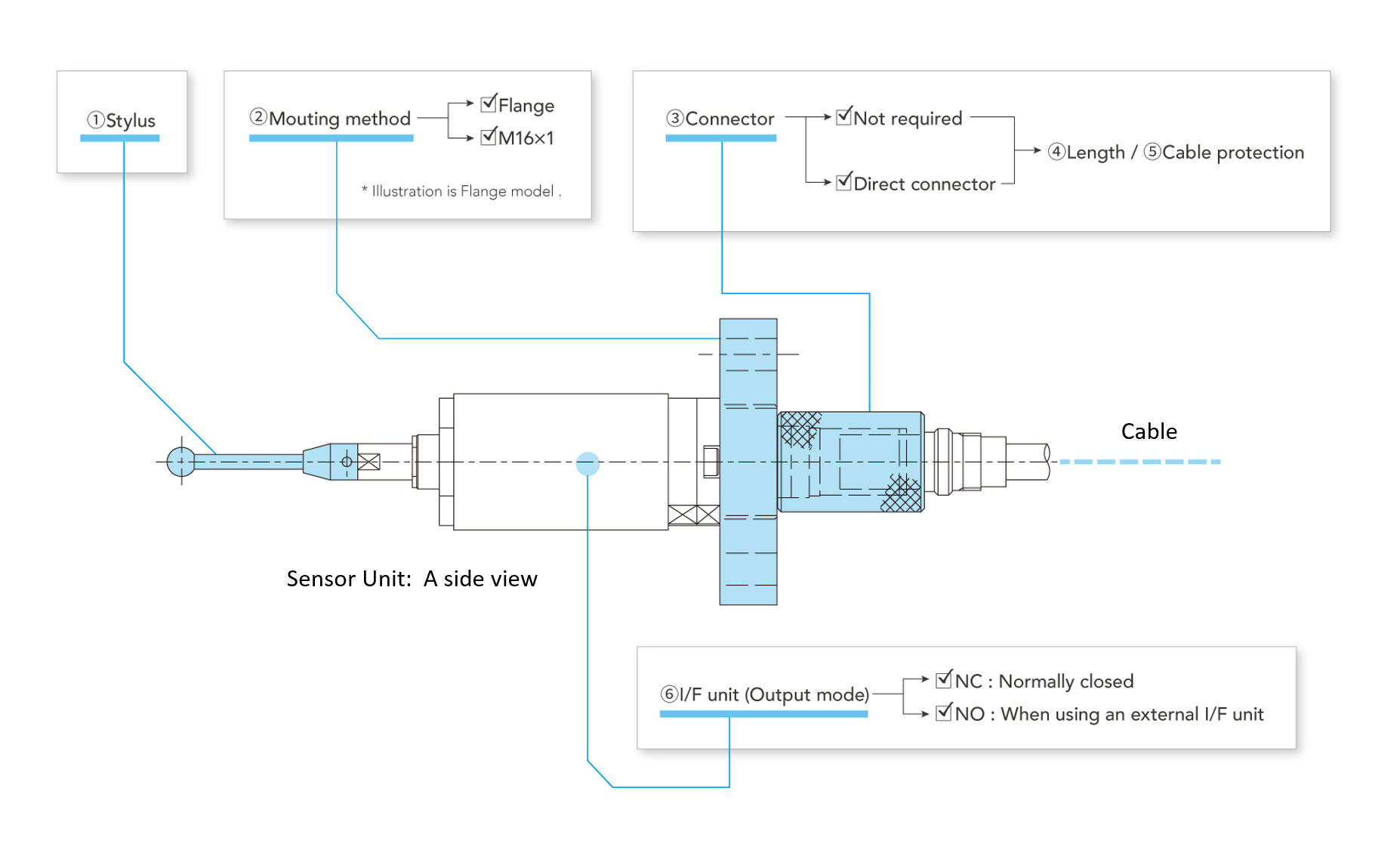

Comprehensive customization options

A wide variety of customization options are available to meet the needs of your operating environment.

Stylus customization, flange mounting, connector type, wireless method option, NO/NC measurement signal output, cord length, among other options are available.

Please inquire us for special installation environments at your convenience.

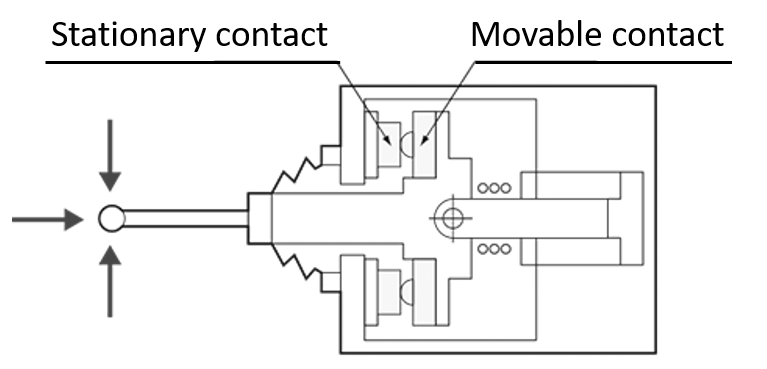

Principle Structure

By placing the touch-probe on the stylus tip against the workpiece or table, a high-precision ON/OFF signal is output, which can be input to NC/PC equipment.

The moving part swings with the three points of contact as fulcrums. Since the contacts play the role of fulcrums, a momentary ON/OFF signal is output when one of the fulcrums is detached.

It is recommended to supply power only during measurement to protect the contact-point.

(*The contact force varies depending on the direction of detection. If the contact force varies depending on the detection direction, a perfect circle will not be formed when measuring a perfect circle shape (roving phenomenon), and thus it is necessary to take this specific quality into account.)

![Wired Touch Probe Sensor for CNC Lathes [K3S Series]](https://metrol-sensor.com/wp-content/uploads/2024/11/K3S_4c-2-1-2-1.png)

![[Case Study] How to Utilize Small Touch Probes with Small Milling Machines](https://metrol-sensor.com/wp-content/uploads/2025/05/2892328468a73b8b95a944aabba2ad84-800x530.jpg)

![[Case Study] Productivity increased more than 4 times! How to utilize “ON-machine measurement” of CNC surface grinders?](https://metrol-sensor.com/wp-content/uploads/2023/11/a11b4bb3ba448d1fa402ac3dc62cc91f-800x530.png)